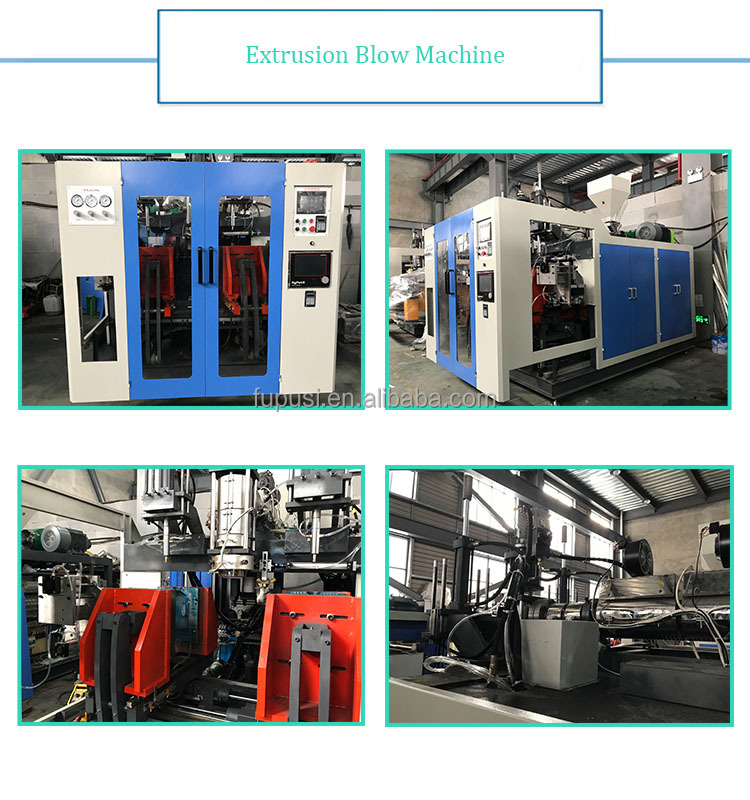

Extrusion Plastic Blow Molding Machine Automatic High Speed Extrusion Blow Molding Machine HDPE PE PP PC PETG LDPE

-

Supplier: Taizhou Fupusi Machinery Co., Ltd. -

Region: Zhejiang, China -

Contact: Mr John Tao -

Price: $18200.00 /set -

Min. Order: 1 set

| Dimensions (L*W*H): | 6.8*4.2*5.8 | station: | Water tank double station extrusion blow molding machine |

| Supply capacity: | 300 sets per year | Core components: | PLC, engine |

| advantage: | High speed, fully automatic, double station | Origin: | Zhejiang, China |

| Weight (ton): | twenty two | Package preview: | |

| Hollow part volume: | 60 | Suitable bottle: | Water and oil spray bottle road guardrail car fuel tank small dropper |

| PLC brand: | mitsubishi | Plastic processing: | PP, HDPE, PC, ABS, PVC, PET, PPR, polystyrene, EPS, PE, EVA, PA, ABS/PP, PE/PP, HDPE/PP, wood plastic, polylactic acid, PETG |

| Warranty: | 1 year | Blow molding type: | Extrusion Blow Molding Machine Blow Molding Bottle Making Machine |

| type: | Extrusion Blow Molding Equipment | Showroom location: | not any |

| Number of screw heating zones: | 5 | Mechanical test report: | not available |

| brand: | Novo | Screw diameter (mm): | 28mm |

| Main selling points: | High speed, fully automatic, double station | Voltage: | customer specified |

| Air pressure (MPa): | 1.0 MPa | Health status: | new |

| Air consumption (m3/min): | 1.8 cubic meters per minute | Year: | Year 2014 |

| Template size (height) (mm): | 1000mm | Screw heating power (kW): | 25 kW |

| Extruder motor power (kW): | 37 kW | Output (kg/h): | 120 kg/h |

| Material: | HDPE LDPE LLDPE HDPE PE PP PC | application: | Plastic bottles, oil barrels, plastic buckets, water tanks, toys, boards, jars |

| automation: | Fully automatic, manual | Applicable materials: | HDPE, PE, PP, PC, PETG, LDPE, |

| Production: | HDPE Extrusion Blow Molding Machine | payment terms: | Western Union, T/T, MoneyGram |

| Applicable industries: | Energy and mining, hotels, household, machinery repair shops, manufacturing plants, restaurants, building supplies stores, retail, food and beverage factories, food stores, clothing stores, advertising agencies, farms, food and beverage stores, construction, print shops, industry | Type of machine: | Automatic PETG Extrusion Blow Molding Machine |

| Power (kW): | 60 | Production Process: | Ocean ball high speed LDPE extrusion blow molding |

| port: | Ningbo port or Shanghai port | Packaging Details: | Export standard seaworthy packaging, using strong film |

| Accumulator capacity (L): | 25 liters | Core component warranty: | 1 year |

| Die heating power (kW): | 4.5 kW | Clamping force (kN): | 700 |

| Template size (width) (mm): | 1050mm | Video outbound inspection: | if |

Forps Machinery Available in packaging containers with volumes from a few milliliters to 100 liters, as well as large containers with capacities up to 120 liters. The machines and molds of Fupus Machinery make the manufacture of blow molded products simple, whether with or without continuous or accumulator parison heads, with technologies such as hydraulic or hybrid drives. The close cooperation between Artin and its clients has contributed to its success.

Forps machines include double station continuous duty series extrusion blow molding machines for 100ml to 10L containers and single station hopper extrusion blow molding machines for 12L to 120L containers.

FPS-D series is a two-stage extrusion blow molding machine for containers from 5ml to 10L, with high reliability, excellent efficiency and flexibility to meet different customer requirements. The machine can process a wide variety of materials including HDPE, LDPE, PP, PVC, TPU, PETG and others. Compared with the S-series machines, the D-type machines can produce faster per hour. The FPS-D machine covers the complete production range from the smallest ampoules or tubes to beverage packaging, cosmetic containers, wide mouth containers and multi-layer containers with visible stripe lines.

1. Suitable for producing 1L-12L fuel bottles, lubricating oil bottles, etc.

2. The inside of the die head is smooth, the curved flow channel has no dead angle, and the inside and outside of the finished product are smooth without lines.

3. The effect of multi-layer co-extrusion, the visible line design of the finished product can be selected to ensure uniform layer thickness. Straight visible lines of uniform width at top and bottom.

4. The machine can be equipped with automatic deburring, finished product take-out device, waste and finished product conveying device, in-mold label, leak detector.

5. This model can be upgraded to a "hybrid type". The moving part of the carriage is designed with a servo motor to achieve no noise, easy operation, accurate positioning, and fast centering of the mold

Extrusion Plastic Blow Molding Machine Automatic Double Station High Speed Blow Molding Machine HDPE PE PP PC

We will be happy to provide you with more details if required.

| maximum. Product volume | (big) | 250 liters |

| dry cycle | (Hours) | 300 |

| Screw diameter | (mm) | 132 |

| Screw aspect ratio | (major diameter/diameter) | 38(30) |

| Screw drive power | (kilowatt) | 320-380 |

| Screw heating capacity | (kilowatt) | 16.7 |

| Number of heating zones | (district) | 8 |

| HDPE maximum output | (kg/hour) | 160 (computer) |

| Oil pump driving power | (kilowatt) | 45 |

| Clamping force | (kN) | Chapter 770 |

| Mold stroke (platen distance) | (mm) | 800-1800 |

| maximum. Die size (width*height) | (mm) | 1200*1720 |

| Die capacity | (big) | 1.9 |

| maximum. Die diameter | (mm) | 620 |

| Mold heat capacity | (kilowatt) | 15 |

FPS-PC25L Extrusion Blow Molding Machine

FPS-PC25L Extrusion Blow Molding Machine is specially designed for producing 5 gallon PC bottles with relatively low capital investment, output up to 60BPH&100 PBH, extrusion blow molding process provides high quality PC water bottles at very attractive cost. In addition, the extrusion blow molding process offers decisive advantages due to the virtually unlimited design freedom with regard to bottle geometry and the easy installation of handles

FPS-S Series Industrial Accumulator Head Extrusion Blow Molding Machine

FPS-S storage head extrusion blow molding machine is mainly suitable for the production of various PE and PP material packaging barrels, tool boxes, auto parts such as fuel tanks, air pipes and other large and medium-sized hollow products with a capacity of 12L-120L. The machine is equipped with an accumulator, and the material storage capacity can reach 12kg, which is the key to manufacturing high-quality large-size industrial containers. The top brand closed-loop hydraulic system guarantees the performance of the machine, and less power consumption.

"A" series is suitable for producing various blow molding products, such as chemical barrels, tool boxes, children's toys, chairs, auto parts, pallets, etc. The machine adopts the design of energy storage die head, which can easily store materials in a short time, and adopts imported hydraulic control system, which makes the operation more reliable and stable. We also employ an advanced parison control system to precisely even out the wall thickness of the product.

Plastic 19 Liter Simple Jar Production Blow Molded Bottle Making Machine

Fully automatic full electric water and oil spray bottle water tank road guardrail car fuel tank plastic extrusion blow molding machine

HDPE extrusion blow molding machine

HDPE Extrusion Bottle Making Machine Plastic Blow Molding Blow Molding Machine

-

plastic machine for the production of water tanks

-

Fully automatic plastic bottle blow molding machine with favorable price

-

Juice plastic popsicle tubes in different shapes

-

HDPE 1 Liter 5 Liter View Stripe Lubricant Lubricating Engine Oil Plastic Bottle Manufacturing Extrusion Blow Molding Blow Molding Machine Price

-

Plastic Mannequin Extrusion Blow Molding Machine

-

Blow molding machine Hdpe

-

Barrel Making Machine 90L 100L 120L Plastic Barrel Molding Machine 230L 210L 200L 160L

-

4L/5L Used Extrusion Blow Molding Machine With Parison Control Used Plastic Bottle Blow Molding Machine

-

blow molding machine with plastic extrusion

-

5000L HDPE water tank three-layer blow molding machine

Other Products

-

$3300.00 / set

$3300.00 / set -

$35000.00 / set

$35000.00 / set -

$10000.00 / set

$10000.00 / set -

$420.00 / piece

$420.00 / piece -

$15000.00 / set

$15000.00 / set -

$2800.00 - $3300.00 / set

$2800.00 - $3300.00 / set