HDPE 1 Liter 5 Liter View Stripe Lubricant Lubricating Engine Oil Plastic Bottle Manufacturing Extrusion Blow Molding Blow Molding Machine Price

-

Supplier: Zhangjiagang Ostar Machinery Co., Ltd. -

Region: Jiangsu, China -

Contact: Mr Jimmy Shi -

Price: $20000.00 / 1 - 1 sets

$19500.00 / 2 - 4 sets

$18000.00 / >=5 sets -

Min. Order: 1 set

Product details

| Weight (ton): | 5.5 | Mechanical test report: | if |

| Blow molding type: | extrusion blow molding | automation: | automatic |

| Dimensions (L*W*H): | 3.2X1.7X2.5M | Health status: | new |

| Packaging Details: | Standard sea freight high quality low price 500ml 1000ml hdpe milk bottle blow molding machine | payment terms: | L/C, Western Union, D/P, T/T, MoneyGram |

| Main selling points: | competitive price | Hydraulic valve: | Japan Oil Research Institute |

| Key words: | Oil bottle blow molding machine | Voltage: | 380V |

| Screw aspect ratio: | 25 | Applicable industries: | Home use, food and beverage factories, food stores, construction works |

| Applicable bottle: | 50-5000ml bottled | Output (kg/h): | 80kg/hour |

| Die heating power (kW): | 5.7 kW | application: | bottle |

| Clamping force(kN): | 68 | brand: | Austrian star |

| Hollow part volume: | 50ml to 5000ml | Accumulator capacity (L): | 0 liter |

| product name: | Drum Blow Molding Machine | Power (kW): | 7.5 |

| Plastic processing: | PP,PE,PE/PP,HDPE/PP | High pressure valve & cylinder: | Taiwan Yadeke |

| Core components: | PLC, engine, bearing, gearbox, motor, pressure vessel, gear, pump | Screw heating power (kW): | 7.2 kW |

| Mold platen size (height) (mm): | 400mm | engine: | Siemens |

| brand: | mitsubishi | Energy saving: | Servo motor system |

| Number of screw heating zones: | 3 | Video shipment inspection: | if |

| Core component warranty: | 1 year | Air pressure (MPa): | 0.6 MPa |

| Extruder motor power (kW): | 22 kW | Key words: | Engineer Blow Molding Machine |

| port: | Shanghai | Material application: | PP PE PVC ABS... |

| Air consumption(m³/min): | 0.5 cubic meters per minute | Showroom location: | Indonesia, Nigeria |

| Screw diameter (mm): | 70 mm | Mold platen size (width) (mm): | 360 mm |

| Supply capacity: | 100 sets per month high quality low price 500ml 1000ml hdpe milk bottle blow molding | Origin: | Jiangsu, China |

| Warranty: | 1 year |

Product Description

extrusion blow molding machine

Extrusion blow molding machines are used to produce various food, toys, beverages, medicines, chemical products, pesticide detergents, water bottles, milk bottles, medicine bottles, oil bottles, plastic balls, cosmetic bottles, lubricating oil bottles, plastic containers. machine is low

It has the advantages of investment, high efficiency, quick and safe operation, easy troubleshooting and easy maintenance.

It has the advantages of investment, high efficiency, quick and safe operation, easy troubleshooting and easy maintenance.

Machine parameters

Specification | unit | KSC-5L | KSC-5L/II | |||

Applicable material | PE PP HDPE PVC.. | |||||

Maximum product volume | large | 5 | 5 | |||

dry cycle | piece/hour | 1100 | 700*2 | |||

Machine size | rice | 3.2*1.8*2.5 | 3.4*2.2*2.5 | |||

machine weight | Ton | 4.0 | 5.5 | |||

clamping force | Potassium | 70 | 70 | |||

Platen distance | mm | 165-525 | 165-525 | |||

Mold moving stroke | mm | 420 | 420 | |||

Template size (W*H) | mm | 360*400 | 360*400 | |||

Maximum mold size (W*H) | mm | 360*400 | 360*400 | |||

Screw diameter | mm | 60 | 70 | |||

Screw aspect ratio | aspect ratio | 25 | 25 | |||

screwdriver power | kilowatt | 15 | twenty two | |||

Screw heating power | kilowatt | 6.5 | 7.2 | |||

Screw screw heating zone | district | 3 | 3 | |||

HDPE output | kg/h | 70 | 80 | |||

Number of mold heating zones | district | 3 | 3 | |||

Mold heating power | kilowatt | 5.7 | 5.7 | |||

Maximum single mode diameter | mm | 145 | 145 | |||

Dual mode center distance | mm | 150-180 | 150-180 | |||

Three-mode center distance | mm | 110 | 110 | |||

Four-mode center distance | mm | 80-90 | 80-90 | |||

total power | kilowatt | 34.7 | 42.4 | |||

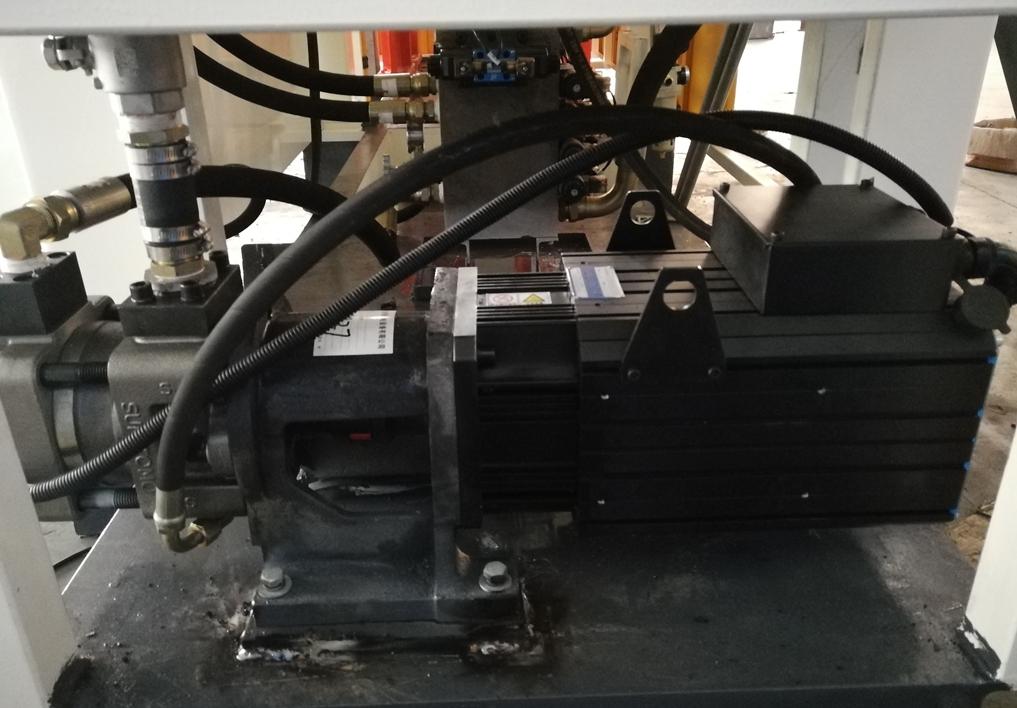

oil pump motor | kilowatt | 7.5 | 7.5 | |||

average energy consumption | kilowatt | 15.5 | 20.5 | |||

blowing pressure | MPa | 0.6 | 0.6 | |||

Air consumption | m3/min | 0.5 | 0.6 | |||

cooling water pressure | MPa | 0.3 | 0.3 | |||

Water Consumption | l/min | 50 | 60 | |||

machine parts

parts

We choose well-known brand components for our machines. Make sure the machine is stable and durable. Each machine will be automatically tested for more than 72 hours to ensure that each machine part is in good condition and will not cause any trouble to our customers.

machine application

machine details

controller panel

The color screen displays English.Technical Settings Data Storage System

100-point parison controller ensures uniform thickness of the finished product.

Optimized switch for easy operation.

Electrical cabinet

Famous brand electrical components ensure durability and stability.

Digital wire connection, convenient for future inspection and testing

Modular components for easy replacement

server system

Adopt high-efficiency servo motors and pumps, save up to 40%-50% power consumption, and reduce your factory manufacturing costs. Low noise and stable working condition.

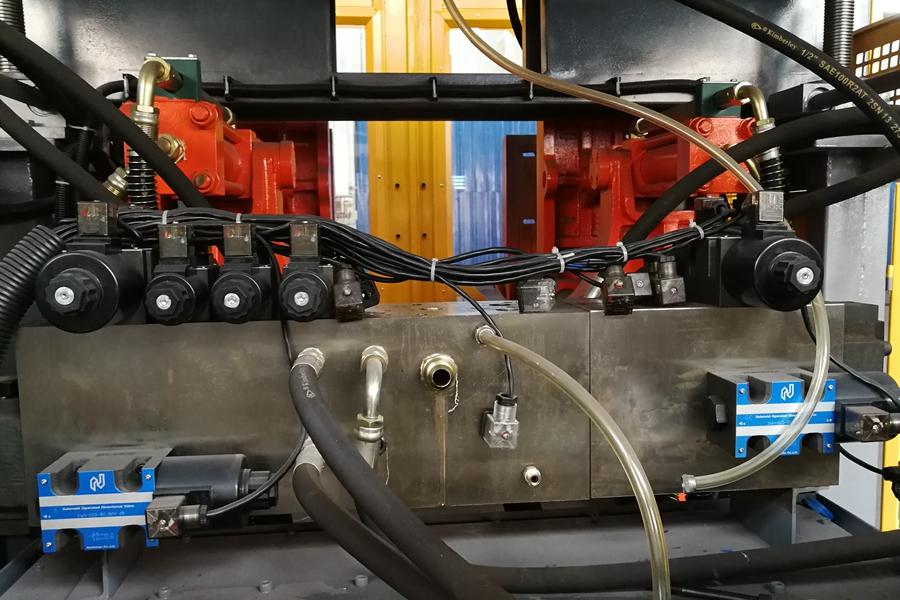

Hydraulic system

Japan/Taiwan famous brand oil pressure valve, proportional control of machine pressure and flow, is a precious movement.

Optimized hydraulic oil system, fast response, precise control action.

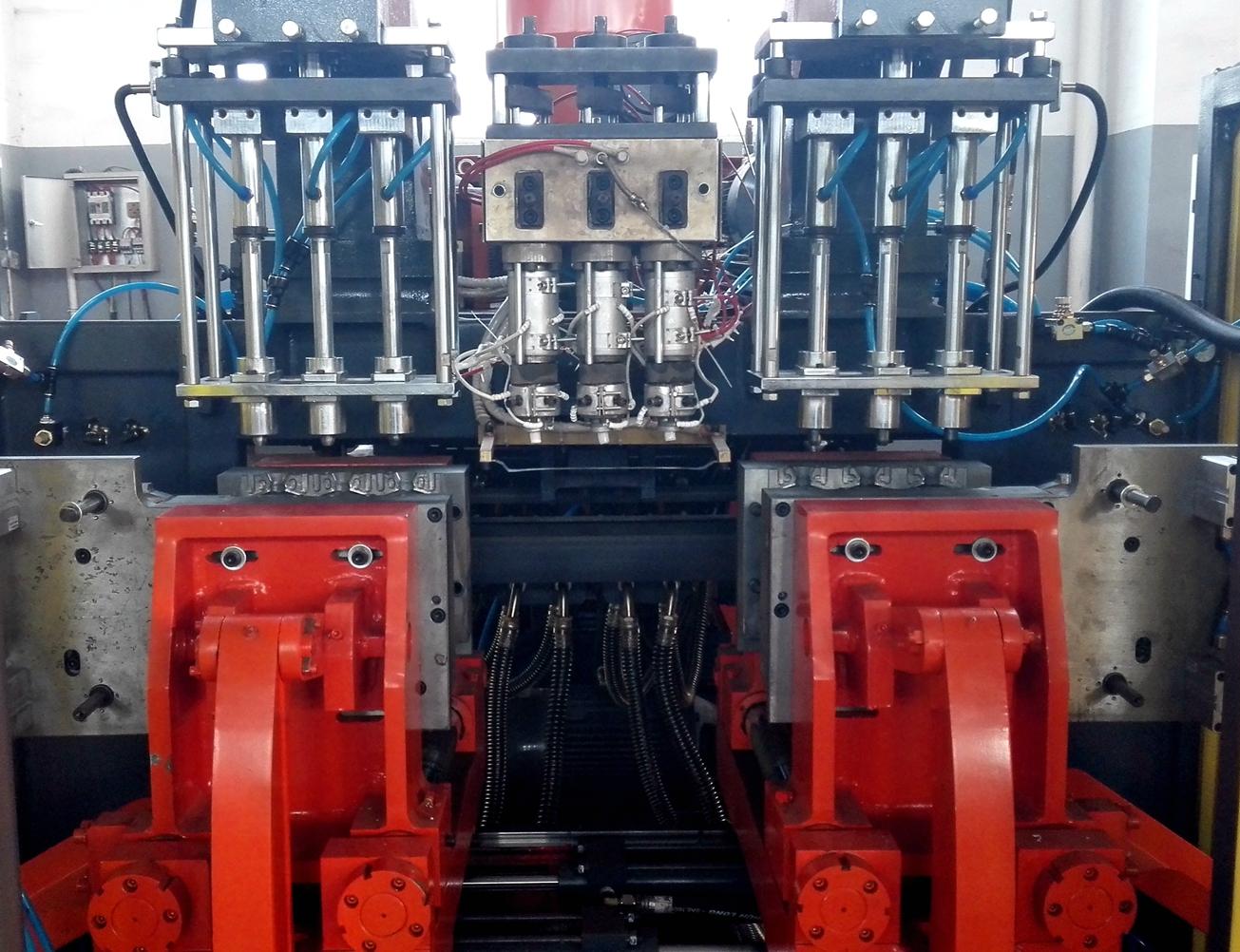

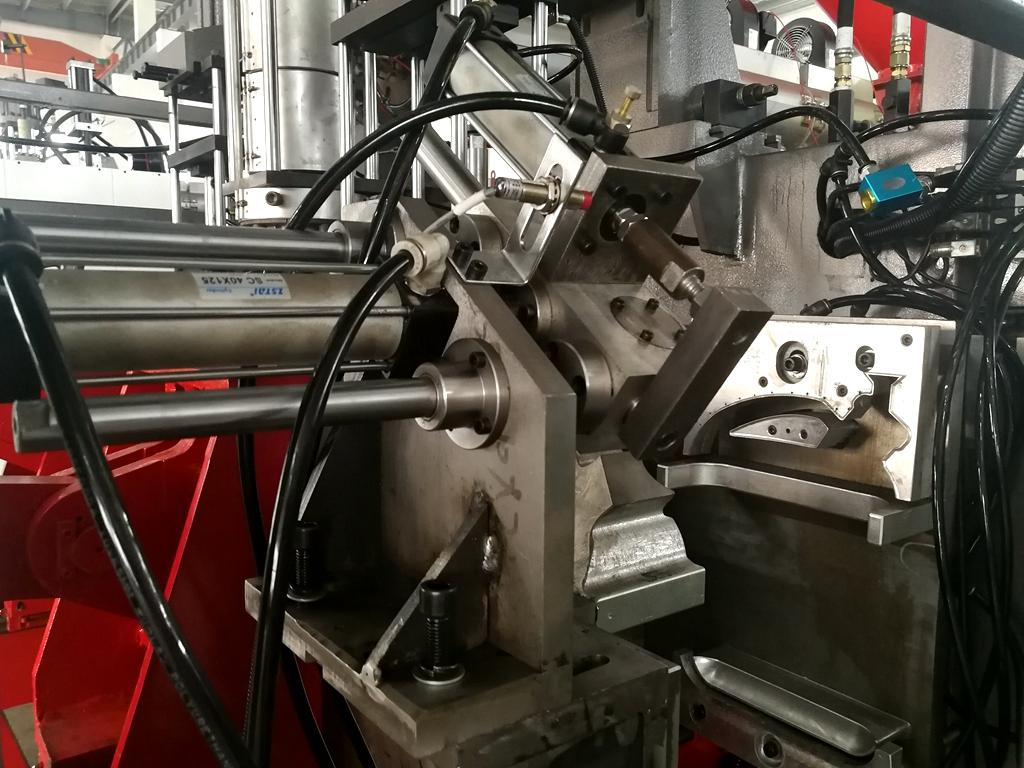

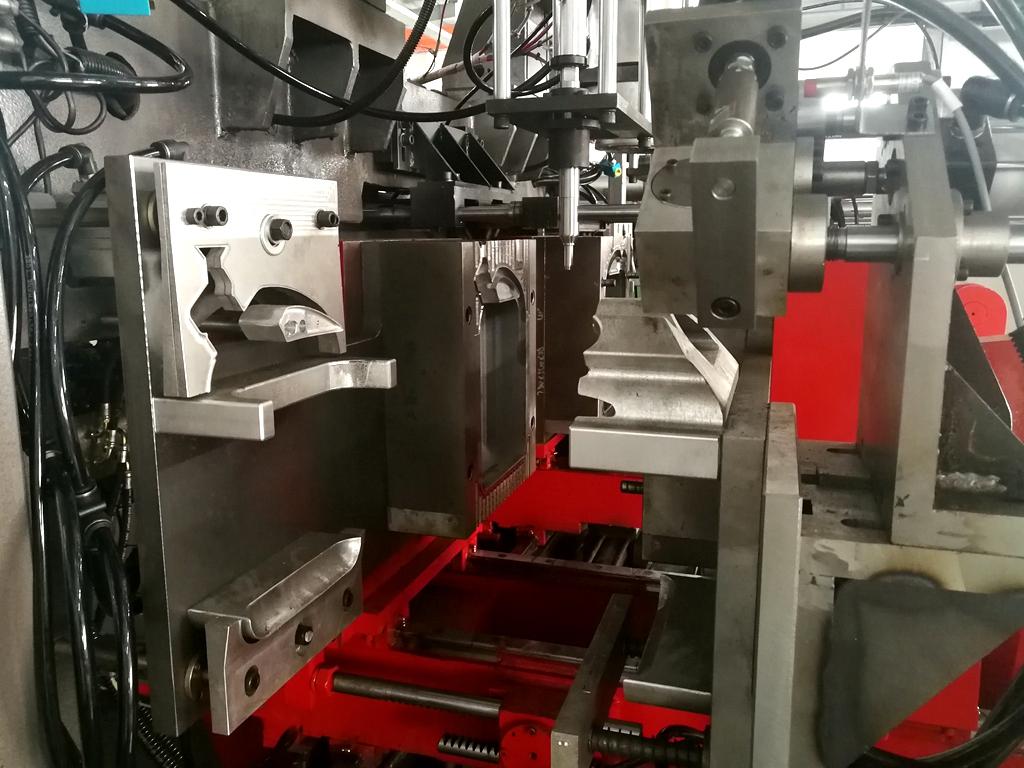

Mold Clamping Device & Die Head

Super strong machine clamping force ensures that the blow mold is locked tightly and the surface of the finished product is better.

Operator safety protection device.

Good material for dies.

extrusion system

High hardness bimetal screw barrel, high plasticization and long life.

High quality gearboxes, motors and inverters.

Specially designed heating belt with high efficiency and low power consumption.

Mold & Auxiliary

blow mold

We have our own mold department, we design drawings, make mold parts, assemble together, test molds on our machines, make sure to run the goods before shipping.

We choose high-quality mold materials, such as P20, aluminum, beryllium copper, for better finished products.

Mold design with optimized cooling system helps to reduce cooling time and increase production speed.

The mold belt is trimmed and is in automatic operation state.

Rotary Bottleneck Cutting

Top hardness cutting head, smooth bottleneck cutting

Automatic Deflashing System

Automatic removal of flash glue, reducing labor

Auxiliary equipment

We provide customers with blow molding machines, blow molds, and necessary auxiliary equipment, such as automatic feeders, crushers, conveyors, air compressors, chillers, leak detectors, in-mold labelers, and external labelers machine, self-adhesive labeling machine, robot, bottleneck trimming machine, automatic packing machine. We provide complete solution, automatic production line.

VIEW MORE

You may like

-

plastic machine for the production of water tanks

-

Extrusion Plastic Blow Molding Machine Automatic High Speed Extrusion Blow Molding Machine HDPE PE PP PC PETG LDPE

-

Fully automatic plastic bottle blow molding machine with favorable price

-

Juice plastic popsicle tubes in different shapes

-

Plastic Mannequin Extrusion Blow Molding Machine

-

Blow molding machine Hdpe

-

Barrel Making Machine 90L 100L 120L Plastic Barrel Molding Machine 230L 210L 200L 160L

-

4L/5L Used Extrusion Blow Molding Machine With Parison Control Used Plastic Bottle Blow Molding Machine

-

blow molding machine with plastic extrusion

-

5000L HDPE water tank three-layer blow molding machine

Other Products

-

$28000.00 - $29000.00 / set

$28000.00 - $29000.00 / set -

$16000.00 - $20000.00 / set

$16000.00 - $20000.00 / set