Food Ultra High Pressure Homogenizing Emulsification Homogenizer Juice Beverage Dairy Milk Homogenizer

-

Supplier: Shanghai Genyond Technology Co., Ltd. -

Region: Shanghai, China -

Contact: Mr WAKIN Yong -

Price: $8000.00 /set -

Min. Order: 1 set

| Supply capacity: | 30 sets per month | brand: | Gansu |

| Packaging Details: | wooden box | Mechanical test report: | if |

| Package preview: | Origin: | China Shanghai | |

| Core components: | PLC | Processing: | Homogenizer |

| After Warranty Service: | Video Technical Support | Core component warranty: | 1 year |

| port: | Shanghai | Dimensions (L*W*H): | L1780*W3050*H2950MM |

| Processing type: | milk drink | strength: | 7.5 kW |

| payment terms: | L/C, Western Union, D/P, D/A, T/T | Showroom location: | not any |

| weight: | 400 kg | Voltage: | 220V/380V/440V 50HZ/60HZ |

| model: | Guojie B | Certification: | CE&ISO9001 |

| Warranty: | 12 months | Video outbound inspection: | if |

| Applicable industries: | manufacturing plant | Marketing Type: | 2020 New Products |

| After-sales service provided: | Engineers available to repair machinery overseas | Health status: | new |

Homogenizerintroduce

The milk homogenizer adopts the process of pressure passing through the adjustable flow-limiting gap to form a comprehensive effect of pressure-loss expansion, explosion, shearing, and high-speed collision, which crushes particles and droplets into extremely small sizes, and at the same time creates an ideal solution or Dispersion of emulsion. Product stability, consistency, mixing, absorbability, nutritional value, shelf life, flavor, color, safety and activity are all realized in homogeneous processing.

Widely used in production, scientific research and technology development in the fields of food, dairy products, beverages, fine chemicals and biotechnology.

Homogenizer Features

1. The transmission noise is lower than the motor noise. The pointer of the pressure gauge is stable, and the swing range of the pointer is less than 2MPa.

2. The crushing particle size is between 0.1 micron and 0.2 micron, and the average particle size is ≤1 micron.

3. The sealing material can work under 150℃ohC. The parts in contact with the material are made of stainless steel, which is resistant to acid and alkali. All valves and plungers are made of special materials, so they are durable and inexpensive. The bearing is also durable because it is made of a special alloy material, the greater the friction, the greater the hardness.

4. LubricationHomogenizerIt is credible that the oil needs to be changed for the first time after 800 hours to 1000 hours of work, and the oil needs to be changed every year thereafter.

5. The higher the pressure, the finer the material, the more uniform the particle size. Models below 30MPA are mainly used for liquid-liquid emulsification. When the pressure is above 30MPA, it plays a role in the dispersion of liquid-solid liquid. When the pressure reaches 60MPA, most of the materials reach a particle size below 2μm. When the material reaches 80MPA, the effect is more obvious. It is mainly used for crushing ultrafine particle materials. 1μm or less. For more than 100MPA, finer particles can be produced. After repeated high-pressure homogenization of some material particles, particle-free materials below 0.1-0.5μm can be prepared

Working Standards:Through the reciprocating motion of the three plungers, the processed material is sent to the homogenizing valve in the form of high pressure, so that the material receives an instantaneous resultant force when it flows through the small gap between the valve disc and the valve seat. Under the action of turbulent flow, cavitation and shear force, the original coarse emulsion is processed into fine, uniform and stable liquid-liquid mixed emulsion or liquid-solid dispersion. The average fineness of emulsification is less than 1um, and the average particle size of solid dispersion is less than 2um. It integrates the functions and principles of internal jet, ultrasonic homogenizer, horizontal pulverizer and ball mill. The material after high-pressure homogenization has the advantages of high stability, reduced stratification, improved storage quality, faster reaction time, and saving additives.

Homogenizer model list

|

Name |

type |

Rated flow L/H

|

preset pressure MPa |

Working pressure MPa |

weight |

Dimensions (cm) |

Power kW

|

|

high pressure Homogenizer |

GJB500-25 |

500 |

25 |

0~20 |

670 |

100×75×110 |

5.5 |

|

GJB1000-25 |

1000 |

25 |

0~20 |

670 |

100×75×110 |

7.5 |

|

|

GJB1500-25 |

1500 |

25 |

0~20 |

720 |

100×75×110 |

11 |

|

|

GJB1000-30 |

1000 |

30 |

0~24 |

720 |

100×75×110 |

11 |

|

|

GJB2000-25 |

2000 |

25 |

0~20 |

1150 |

100×75×110 |

18.5 |

|

|

GJB2500-25 |

2500 |

25 |

0~20 |

1250 |

100×75×110 |

twenty two |

|

|

GJB3000-25 |

3000 |

25 |

0~20 |

1350 |

100×75×110 |

30 |

|

|

GJB4000-25 |

4000 |

25 |

0~20 |

1400 |

100×75×110 |

37 |

|

|

GJB5000-25 |

5000 |

25 |

0~20 |

2000 |

100×75×110 |

45 |

|

|

|

|

|

|

Zhengyang Machinery Industry Group

It has 6 food machinery and packaging machinery factories in China.

Shanghai Genyang Technology Co., Ltd.; Zhangjiagang Jinyuan Machinery Co., Ltd.

Shanghai Jiuyu Industrial Co., Ltd.; Shanghai Qi Food Machinery Co., Ltd.

Huatuo Machinery; Nantong Yihai Machinery; Kunshan Kaipaike Machinery

Our products have been exported to more than 160 countries, and the sales volume will reach 80 million US dollars in 2022, with an average annual growth rate of more than 10%.

Genyond machine has more than 100 installation engineers for overseas projects.

You just need to provide us with your ideas on the final product, processing capacity, packing way, and we will make suggestions for your review. You can also give us your budget, and we can also design a production line to meet your budget accordingly.

Satisfied items will be given; long-term cooperation will come.

-

Commercial 100L 200L 300L 500L Stainless Steel Milk Machine Milk Homogenizer

-

Stainless steel milk homogenizer 100-150 bar - 100 l, for the small dairy industry

-

100/200/300/500L Dairy Machinery High Pressure Pasteurizer Yogurt Milk Juice Homogenizer

-

Export hot selling homogenizer

-

High quality food hygiene 1000L/H 25mpa milk homogenizer

-

Industrial 100-1000L Milk High Pressure Homogenizer

-

customize liquid tank homogenizer for mixing emulsifier with stainless steel stirrer mixer

-

High Pressure Milk Pasteurizer Milk Homogenizer

-

Ice cream homogenizer price

-

2018 cheapest high pressure small milk homogenizer price

Other Products

-

$5000.00 / set

$5000.00 / set -

$80000.00 / set

$80000.00 / set -

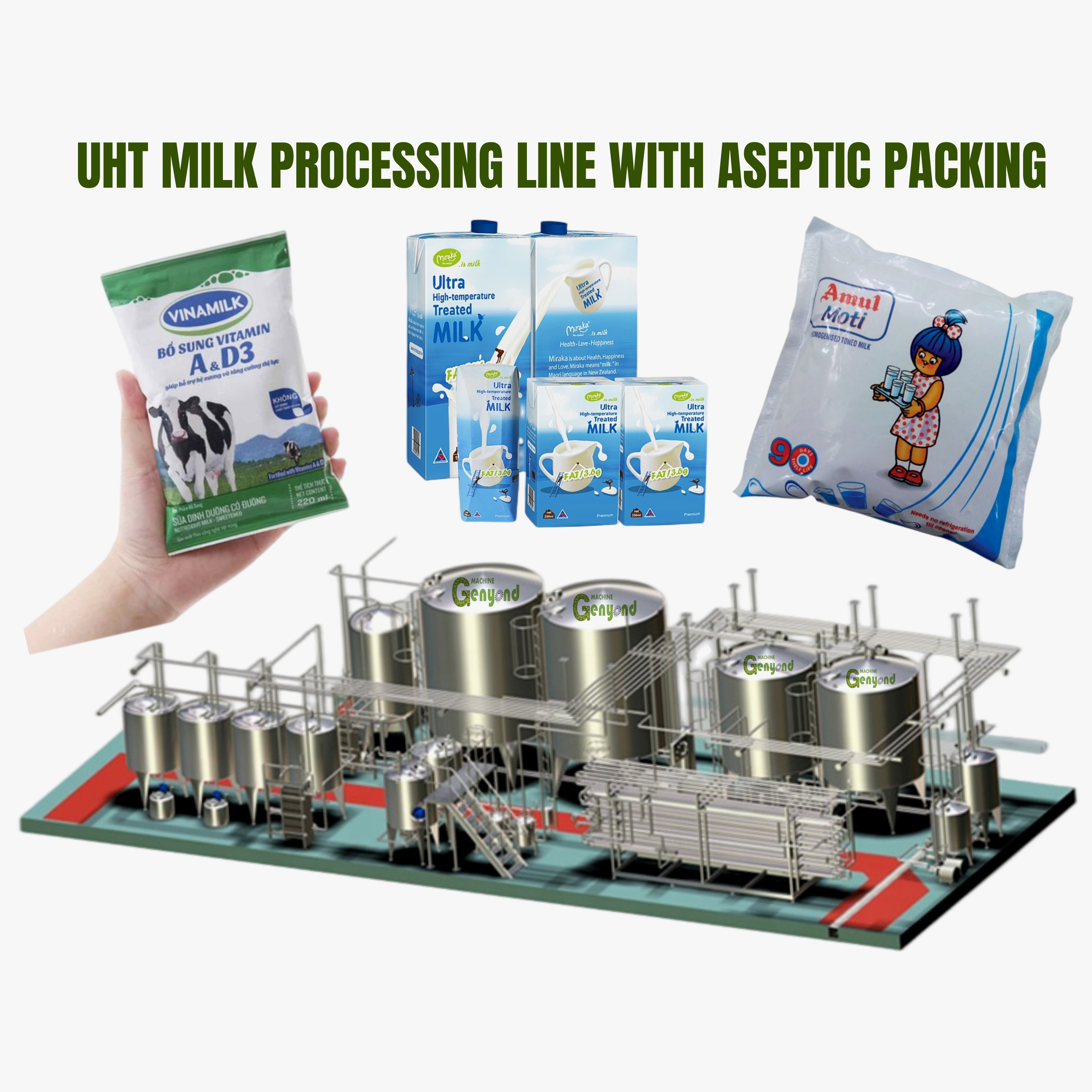

$120000.00 - $150000.00 / set

$120000.00 - $150000.00 / set -

$8888.00 / set

$8888.00 / set -

$80000.00 / set

$80000.00 / set -

$5000.00 / set

$5000.00 / set -

$2000.00 / set

$2000.00 / set -

$1000.00 / set

$1000.00 / set -

$5500.00 / set

$5500.00 / set -

$350.00 / set

$350.00 / set