Heavy duty industrial waste tire shredder, scrap car tire shredder, tire shredding

-

Supplier: Gongyi City Yuxiang Heavy Machinery Co., Ltd. -

Region: Henan, China -

Contact: Mr Jack Chen -

Price: $5000.00 /set -

Min. Order: 1 set

| product name: | metal shredder | Core component warranty: | 1 year |

| Plastic Type: | pvc | Shaft design: | double |

| Main selling points: | multifunctional | use: | waste plastic shredder |

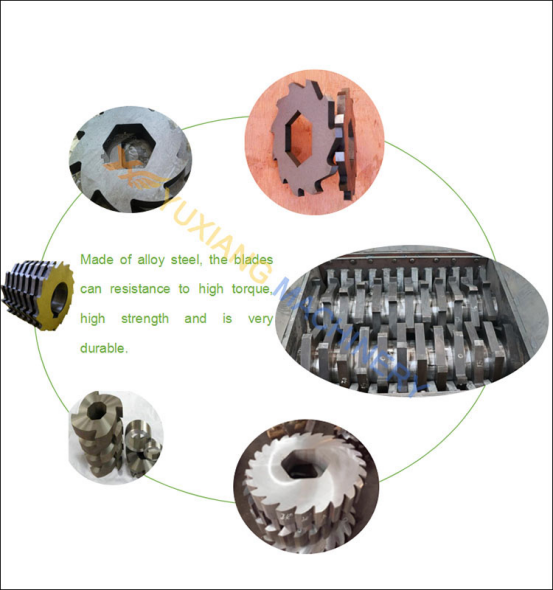

| Blade material: | high speed steel | Recycled material: | shredding scrap metal |

| brand: | Yuxiang | Warranty: | 1 year |

| Packaging Details: | Metal Shredder: Small models are packed in plywood boxes, and large models need to be directly loaded into containers | Applicable industries: | Building material stores, machinery repair shops, energy and mining |

| port: | Qingdao, Tianjin | capacity: | 2-60 tons/hour |

| weight: | 1-100 tons | Health status: | new |

| Weight (ton): | 10 | Mechanical test report: | not available |

| Core components: | gearbox | Function: | crushed wire |

| Origin: | China | application: | metal plastic wood bottle film |

| Power (kW): | 100 | Video outbound inspection: | if |

| Dimensions (L*W*H): | 2000*1000*1500 | Supply capacity: | 100 sets per month |

| Marketing Type: | 2020 New Products | Maximum production capacity (kg/h): | 2500 |

| Type of machine: | plastic crusher | Showroom location: | not any |

| Voltage: | 380V/50HZ,380V | Power (watts): | 100 kW |

| payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram | Package preview: | |

| Production capacity (kg/hour): | 100 - 2500 kg/h |

Heavy duty industrial waste tire shredder, scrap car tire shredder, tire shredding

|

The metal shredder uses the working principle of shearing, tearing and extrusion to process materials and crush different solid wastes, and has good effects on hard and soft materials. It is often used in environmental protection industries such as waste disposal, resource recovery, and waste incineration pretreatment. |

|

|

|

All small metal shredders adopt PLC automatic control system, with automatic reverse control system in case of overload. The shredder is easy to disassemble and replace, and is suitable for shredding large, thick and hard materials. |

Metal Shredder Technical Parameters

| Model | JL-2600 | JL-1900 | JL-1500 | JL-1200 | JL-1000 | JL-600 |

| Spindle power (kw) | 4-160*2 | 4-90*2 | 4-45*2 | 4-37*2 | 4-30*2 | 4-15*2 |

| Spindle speed (rev/min) | 16-18 days | 14-16 days | 14-16 days | 18-20 days | 18-20 days | 18-20 days |

| Production capacity (t/h) | 25-60 | 10-25 days | 8-18 days | 6-15 | 5-10 | 2-5 |

| Number of cutterheads | 40 | 40 | 30 | 28 | 30 | 26 |

| Due to different materials, the number of blade teeth and the number of blades are also different. You can customize. | ||||||

| Cutter diameter(mm) | Φ720 | Φ560 | Φ530 | Φ372 | Φ360 | Φ260 |

| Borken Size(cm) | 3-10 | 3-10 | 3-10 | 3-10 | 3-10 | 3-10 |

| Dimensions (mm) | 8200*4000*4300 | 8000*2500*2400 | 4000*1700*2400 | 3200*2000*1900 | 3000*2000*1900 | 2600*2000*1900 |

| Weight (tons) | 36 | 15 | 12 | 6 | 5 | 2.5 |

Tip:

1. The above metal shredder is our standard equipment. For different materials, the standard may be different. If you want to know more details or specific requirements, please contact us in your free time.

2. We can provide you with welded, detachable and blade holders for metal shredders. You can communicate with our sales representative to confirm the suitable blade you need.

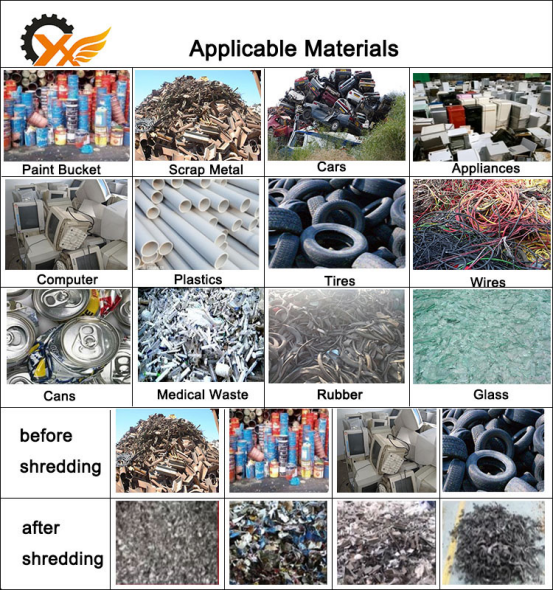

Applicable materials for metal shredder

A wide variety of materials including scrap tires, scrap metal, rubber, and more.

Details of metal shredder

Packaging and Shipping

Packaging: according to the specific size of each shredder, it is packed in wooden boxes, which is suitable for long-distance transportation and various transportation methods.

Delivery: 20-25 working days after receiving customer deposit.

pre-sale service:

Be a good consultant and assistant to customers

Select the device model;

Design and manufacture products according to the special requirements of customers;

Training technicians for customers;

Sale service:

Respect customers, consider all aspects and details for customers

Inspection of products before delivery;

Let customers know about the transportation situation;

After-sales service:

We promise high-quality after-sales service!

Assist customers to prepare the first construction plan;

Equipment installation;

Command the front-line operators on site;

Take the initiative to quickly eliminate on-site failures;

Provide repair of bulky items;

-

-

Plastic Crusher/Powerful Granule/Cutter WSGE-400/High Quality Film Powerful Plastic Crusher

-

Efficient and multifunctional crushing rubber/tire plastic crusher grinder for sale

-

waste plastic shredder pet shredder for shredding plastic

-

Small Portable Dual Shaft Household Scrap Metal Tire Plastic Coconut Pallet Mobile Tire Shredder Metal

-

Double shaft shredder edge blade

-

Professional large-scale 2000 type scrap iron shredder, scrap steel shredder, waste tire shredder

-

Industrial Type 1200 Plastic Waste Wood/Metal/Rubber/Plastic/Scrap/Shredder Blades

-

Small waste plastic recycling machine/metal shredder/metal shredder

-

Automatic Plastic Shredder Industrial Heavy Duty Single Shaft Steel Shredder Wood Shredder

Other Products

-

$2500.00 - $3000.00 / set

$2500.00 - $3000.00 / set -

$3600.00 / set

$3600.00 / set