Diamond knurling mold China factory direct sales high quality thread rolling mold

-

Supplier: Ningbo Henghui Thread Tools Co., Ltd. -

Region: Zhejiang, China -

Contact: Mr Tony Wang -

Price: $60.00 /set -

Min. Order: 1 set

Product details

| Packaging details: | wooden box | Supply capacity: | Thread rolling mold factory produces 10,000 sets per month |

| Customization support: | OEM, ODM, OBM | usage: | External thread forming |

| Certificate: | ISO9001:2008 | product name: | Thread rolling die |

| Material: | Cr12MoV/SKH9/M2 | Advantage: | Wear resistance |

| hardness: | HRC60-67 | payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram |

| Mold type: | Thread rolling die | Minimum order quantity: | 1 set |

| standard: | International Organization for Standardization | port: | Ningbo Port |

| Place of origin: | China | Finish: | Bright (uncoated) |

| Warranty: | 1 | pack: | wooden box |

Product Description

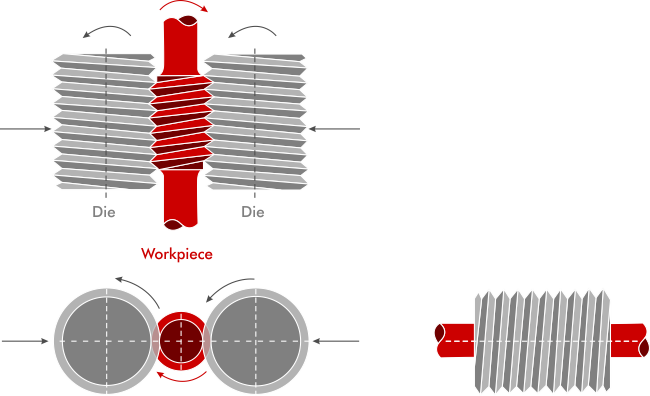

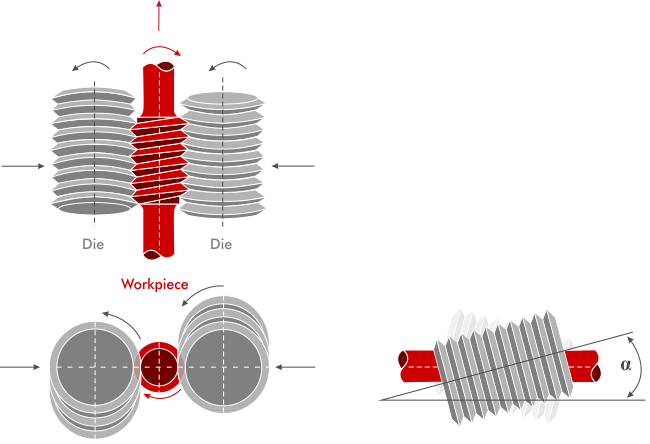

Cylindrical thread rolling moldA process using two or three rolling dies, where the workpiece is usually placed on a supporting blade. At least one (1) rolling slide has a feed motion to perform the forming process. At the same time, the mold contacts the workpiece and rotates synchronously to form the profile.

feed scroll

Feed thread rolling is based on one parameter: workpiece lead = thread rolling die lead. This results in synchronized rotational motion

parts and die. No axial movement occurs. The necessary rolling force is determined by the thread diameter and length.

parts and die. No axial movement occurs. The necessary rolling force is determined by the thread diameter and length.

- Through rolling:

When the workpiece profile is longer than the maximum length, always use through-feed thread rolling. Rolling die width.

There are 4 different types of through-feed molds:

1.Ring Mold: A grooved mold without any lead. The lead angle is produced by the rotation of the mold.

2.Accelerate molds: Increase productivity.

3.Spiral slow feed mold: reduces power requirements,

4.Continuous rolling type: suitable for automatic feeding machines.

There are 4 different types of through-feed molds:

1.Ring Mold: A grooved mold without any lead. The lead angle is produced by the rotation of the mold.

2.Accelerate molds: Increase productivity.

3.Spiral slow feed mold: reduces power requirements,

4.Continuous rolling type: suitable for automatic feeding machines.

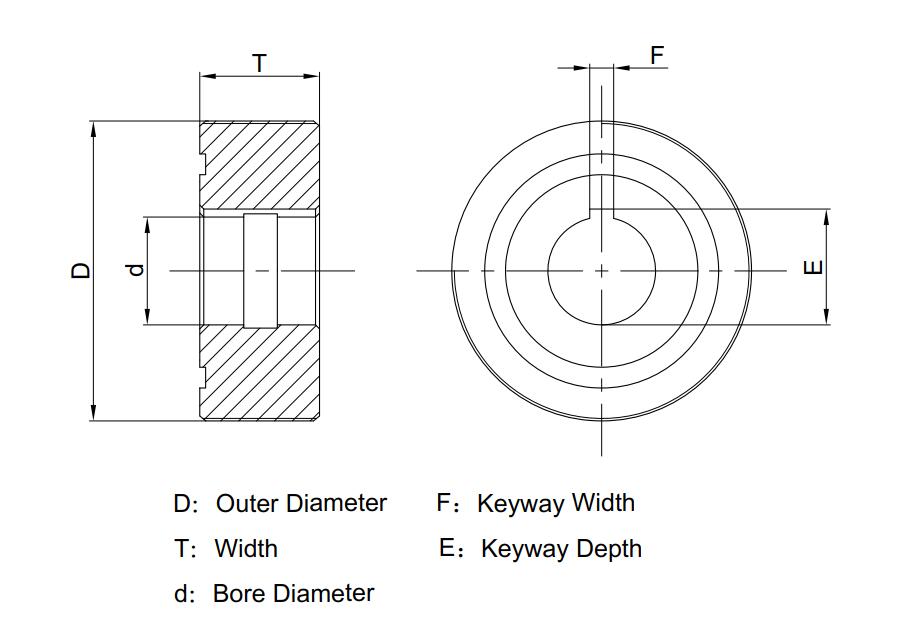

How to order cylindrical thread rolling die

feed to feed

Aperture (d):

Outer diameter (D):

Thickness (T):

Keyway depth (E):

Keyway width (F):

Thread type: (such as M8*1.25,1''-8UNC...)

Headed fully threaded bolts

Headless fully threaded bolts

Partially threaded bolts

Please indicate if it is used for B7 material or has special design for wind power.

Outer diameter (D):

Thickness (T):

Keyway depth (E):

Keyway width (F):

Thread type: (such as M8*1.25,1''-8UNC...)

Headed fully threaded bolts

Headless fully threaded bolts

Partially threaded bolts

Please indicate if it is used for B7 material or has special design for wind power.

VIEW MORE

You may like

-

SUNTECHMACH thread die dimensions and

-

Low price factory supply round round thread rolling die cylindrical wire nail thread die

-

Cylindrical thread rolling dies for high speed steel processing

-

NPT Thread in Feed China Factory Direct Sales Thread Rolling Dies

-

Grooved plane thread rolling die simplex high precision thread rolling die

-

TG Tools Imperial High Speed Steel Threaded Round Dies

-

TG Tools high carbon steel high speed round steel

-

Trapezoidal/trapezoidal bolt mold factory direct sale cylindrical thread rolling mold wooden box ISO long tool life 1 set

-

TG Tools Mertric HSS Alloy Steel Threaded Die

-

China factory direct selling high quality round thread rolling dies

Other Products

-

$60.00 / set

$60.00 / set -

$16.00 / set

$16.00 / set -

$60.00 / set

$60.00 / set -

$60.00 / set

$60.00 / set -

$16.00 / set

$16.00 / set -

$16.00 / set

$16.00 / set -

$16.00 / set

$16.00 / set -

$100.00 / set

$100.00 / set -

$100.00 / set

$100.00 / set -

$100.00 / set

$100.00 / set

Related Search

oil pressure sensor factory direct sale

high quality carbide roll rings

brass knurled molding insert

china factory laundry washing

high quality china car seat protector

factory direct computer hardware

loop factory direct bow

high quality china underground car parking

factori direct chainsaw suppliers

high qualiti diamond powder suppliers