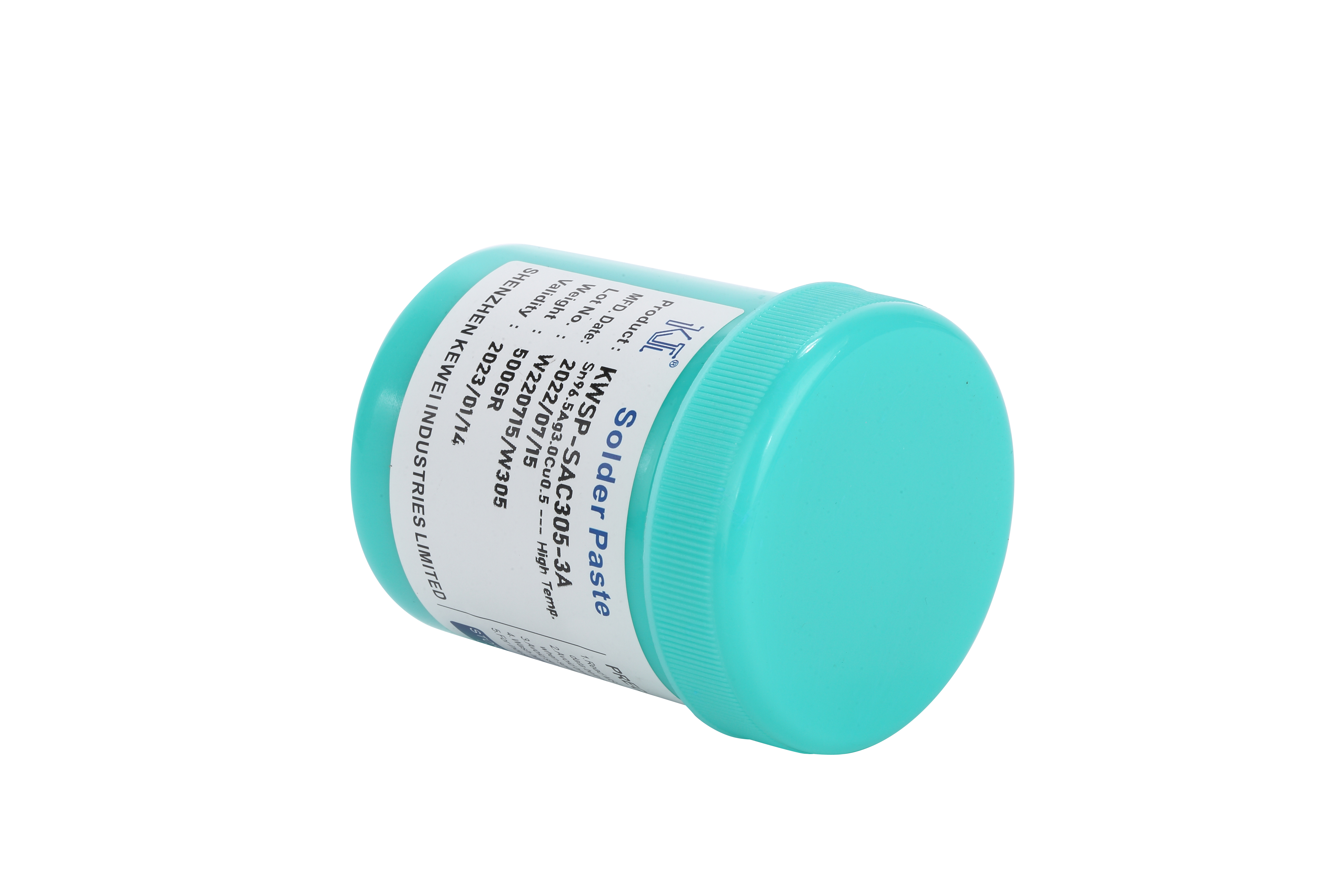

Sn96.5/Ag3.0/Cu0.5 SAC305 Lead Free Solder Paste High Temperature Solder Paste

-

Supplier: Shenzhen Kewei Industries Limited -

Region: Guangdong, China -

Contact: Ms Wendy Cheung -

Price: $27.50 / >=20 pieces -

Min. Order: 20 pieces

| product name: | Lead-free solder paste | Viscosity: | 190±30Pa`s |

| standard: | 500g/bottle | Customization support: | OEM, ODM |

| Material: | Sn96.5%Ag3.0%Cu0.5% | Warranty: | 12 months below 0℃ |

| Gross weight of single piece: | 0.600kg | brand: | KI |

| Conductivity: | Accounting for 13.0% of IACS | Sales unit: | Single product |

| Powder size: | 20-38 microns | Place of origin: | Guangdong, China |

| Package preview: | Flux content: | 11.5±0.5% | |

| Melting point: | 217-227℃ | Packaging details: | 500g/bottle |

| Single piece packaging size: | 38X24X23cm | Material: | Tin/Silver/Copper |

| feature: | Excellent welding performance |

Specification | ||

alloy composition | Sn96.5Ag3.0Cu0.5 | |

Halogen(W/F) | Halogen-free | |

Metal content% | 90±0.5% by weight | |

Powder size | 20~38um (optional) | |

Flux type | RMA no clean | |

Viscosity range | 190±30Pa/s | |

Expansion rate | >80% | |

Tin bead test | <3 | |

melting point | 217℃ | |

Advantages 1.

Less residue and high insulation resistance.

Use no-clean flux, and there will be no residue on the product surface after soldering. It also maintains a transparent appearance and high insulation resistance.

Advantage 2.

The viscosity is suitable and there is no collapse or offset.

By using our own formula and environmentally friendly flux, our solder paste maintains good thixotropic properties and stable viscosity. And our solder paste has excellent thermal collapse protection, which will provide quality assurance for production.

Advantage 3

Strong wettability and high tin crawling performance.

Wettability and soldering properties will determine soldering quality.

We also have powerful grinding machines that can provide different sizes of solder powder. Powder diameters are available from 5μm to 75μm. Suitable for different kinds of production requirements.

Advantage 4.

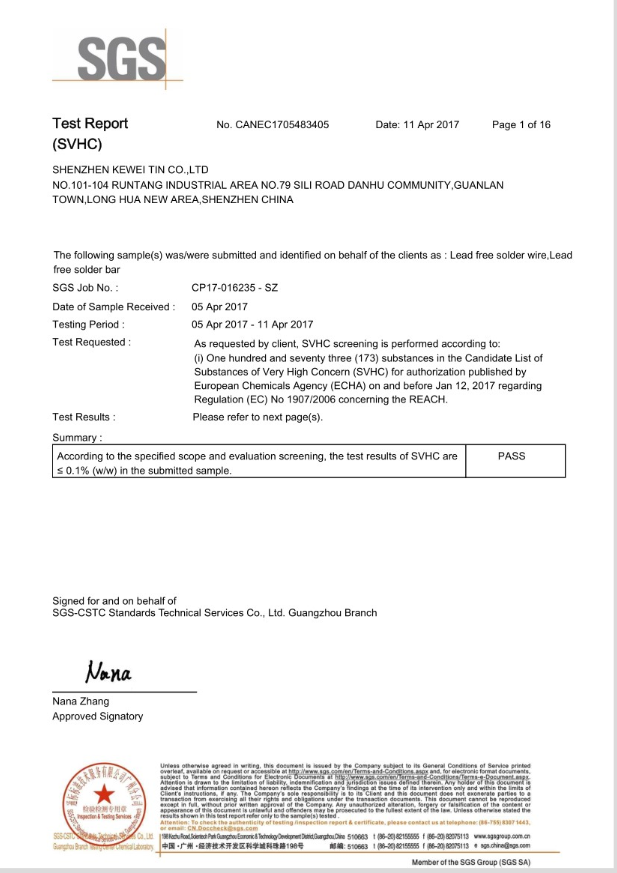

Directly from the manufacturer, dust-free workshop.

Our factory is located in Shenzhen, China, and we have our own factory to manufacture solder wire/solder bars.

There is also an independent solder paste factory equipped with a dust-free studio. Make sure the product is clean and pure.

We also work with China's largest mine suppliers to ensure our stable, fresh supply of raw materials.

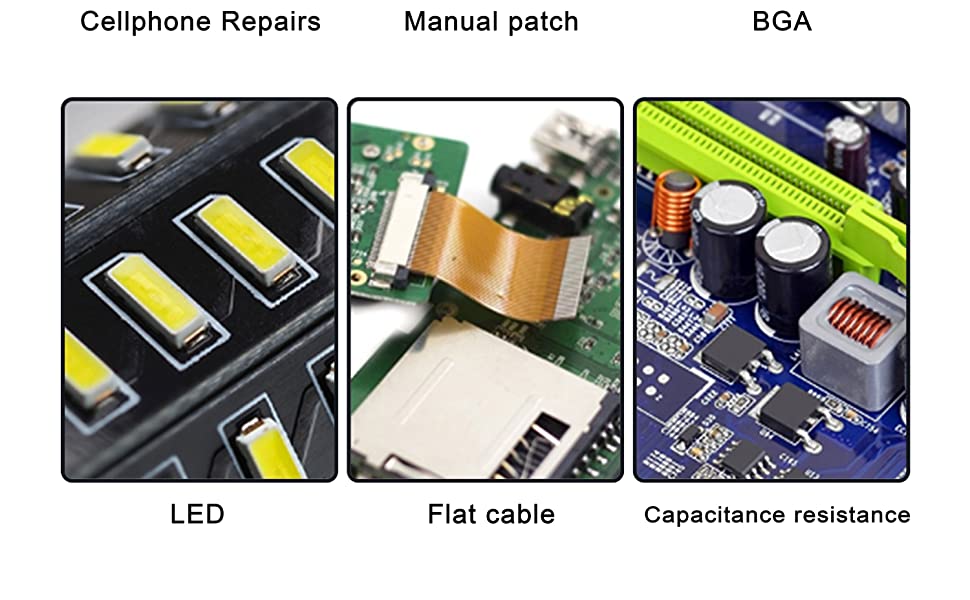

Solder paste application.

Sn96.5/Ag3.0/Cu0.5 solder paste is widely used in PCB, BGA, CSP and soldering repair. We have low halogen and halogen-free types. Can reach industry standards. It has the characteristics of rapid removal of metal surface oxide layer, strong bonding performance between components and metal, non-conductive insulation, rapid wetting, less smoke and less residue. We also produce high-temperature solder paste, low-temperature solder paste, medium-temperature solder paste, flux, tin-lead solder paste, Sn63Pb37, Sn60Pb40, Sn50Pb50, Sn62.8Ag0.4Pb36.8, Sn62.9/Pb36 and other models.9/Ag0 .2. Lead-free solder paste, low-halogen solder paste, halogen-free solder paste, and solder paste flux.

Widely used in: laptops, computers, mobile phones, home appliances, LED, SMT, SMD, PCB industries, etc.

TranSpoRT.

For solder paste shipping, it is best to ship by air. And the shipping time is preferably less than 5 weeks.

start using.

After receiving the solder paste, it should be stored in the refrigerator for 2 to 4 hours before normal production begins.

And after taking the solder paste out of the cold storage, do not open it immediately. To prevent fogging, it must be placed at room temperature (2-4 hours) and the solder paste temperature returns to 25°C before it can be opened, stored and used.

Storage.

Used solder paste must be stored in a clean, pollution-free empty bottle, sealed and refrigerated, and cannot be mixed with new solder paste. The shelf life of solder paste is 6 days after opening. If the storage period exceeds 6 days, please discard it to ensure its production quality.

There are also validity periods at different temperatures:

0-10℃: 6 months (sealed storage)

>10℃: 15 days (sealed and stored)

After opening: 6 days (keep sealed)

attention.

If you accidentally contaminate your hands and feet, wash them immediately with soap and water. Do not knead them with your hands. Use alcohol to scrub the remaining residue.

Printing conditions.

scraper | Hardness 80-90 degrees |

Board material | Stainless steel mesh mold or wire mesh |

Material | rubber or stainless steel |

Board thickness | Stainless steel template 0.12-0.25mm |

Squeegee speed | 10-150 - mm/sec |

environment | Temperature: 25±5L; Humidity: 40-60%RH |

Blade angle | 60-90 |

wind | Will destroy the adhesive properties of the paste |

Reflow oven.

Different temperatures are set according to different alloys and machine characteristics. You also need to consider the PCB layout, circuit width and then adjust the processing temperature.

The following are recommended parameters for a reflow oven.

(1) Heating up to reflow soldering: The heating rate is set to 1℃~3℃/second. In the preheating zone, heating up too fast will destroy the fluidity and composition of the solder paste. This will cause solder spray and solder ball problems.

(2) Preheating zone: The temperature is 140~170℃, and the time is 80~150 seconds. If the temperature is too low, there will be problems with the solder not completely melting.

(3) Reflow soldering: peak temperature. Set at 210℃~230℃. When the temperature. ≥183℃, time is set at 60~100 seconds. ≥200℃ set for 40~80 seconds.

(4) Cooling: cooling rate <4℃/second.

-

Solder paste 500g high/medium/low temperature halogen-free lead-free no-clean solder paste soldering station flux

-

BST-223-UV 10cc SMD BGA Lead Free Soldering Flux

-

Factory hot sale submerged arc welding wire sj431 flux

-

Bst-21503a 150g High Quality Solder Paste For Led Bga Smd Pga Top Sale Solder Paste Flux Grease

-

FLUX FLUXPLUS 10CC 10G NC-D500 NORDSON soldering flux soldering lead-free soldering fluxes Liquid soldering EUROPE warehouse

-

MECHANIC Solder Paste XGSP30 Sn63/Pb37 Medium Temperature Glue Flux Mobile Phone PCB Repair

-

Bst-706 lead-free solder paste low temperature solder paste BGA solder paste Sn42/Bi58 10cc

-

New Arrival Welding Magnet Set Magnetic Welding Stand Adjustable Welding Magnet

-

Hot sale SMT solder paste Sn63Pb37 high performance solder paste

-

Refrigerated Brazing Powder

Other Products

-

$0.10 - $0.20 / piece

$0.10 - $0.20 / piece -

$14.30 / piece

$14.30 / piece -

$28.64 / piece

$28.64 / piece -

$4.50 / roll

$4.50 / roll -

$2.53 / roll

$2.53 / roll -

$11.21 / piece

$11.21 / piece -

$4.00 / piece

$4.00 / piece