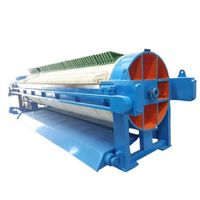

Durable, high quality water filtration membrane filter press with cloth cleaning drip tray

-

Supplier: Shanghai Junyi Filter Equipment Co.,Ltd -

Region: Shanghai, China -

Contact: Ms Susana Wang -

Price: $10000.00 / 1 - 2 sets

$9500.00 / >=3 sets -

Min. Order: 1 set

Product details

| product name: | Durable, high-quality water filtration membrane filter press | Mechanical test report: | if |

| Advantage: | Fully automatic | Marketing type: | 2020 new products |

| Packaging details: | wooden box | Frame material: | Carbon steel, wound stainless steel, wound PP board... |

| Voltage: | 220V, 380V, 460V, customized | Core components: | PLC, motor, board |

| Health status: | new | Package preview: | |

| payment terms: | L/C, Western Union, T/T, MoneyGram | Dimensions (length*width*height): | by model |

| Supply capacity: | 200 sets per month | Function: | Solid-liquid separation |

| Showroom location: | not any | Video outbound inspection: | if |

| Filter press type: | Membrane filter press | port: | Shanghai Port, Qingdao Port, Guangzhou Port or upon request. |

| Filter area: | 30-1000 square meters | Automatic level: | automatic |

| Filter chamber volume: | 412-20000L | Applicable industries: | Manufacturing plants, food and beverage plants, farms, construction projects, energy mining, water treatment, chemicals, metallurgy, rare metals |

| Place of origin: | China | strength: | 4kW-11kW |

| weight: | 6500kg | brand: | Junyi |

| Warranty: | More than 1 year | Filter plate material: | Diaphragm |

| type: | Automatic filter press | Core component warranty: | 1 year |

| application: | Petroleum, food, brewing, fine chemicals, sewage treatment, etc. |

Product Description

brief introduction | Junyi series fully automatic diaphragm filter press uses a diaphragm and a chamber filter plate to form a filter chamber. The board is made of reinforced PP material, and the membrane material and PP board are inlaid together, which is strong and reliable, not easy to fall off, and has a long service life. |

work process | Two steps: filtration and cake drying. Under the pressure of the feed pump, the slurry is pumped into the filter chamber, and the solids and liquids in the slurry are separated by the filter media (filter cloth). After the solids in the filter form a filter cake, air is introduced into the membrane to fully squeeze the solids in the filter chamber and reduce the moisture content. |

Function | Automatic pressing plate, automatic pressure maintaining, automatic pulling plate. We can also choose to equip it with a cloth washing machine, drip tray, belt conveyor, etc. Equipped with a variety of safety devices to ensure the safety of operators and the normal operation of the filter press. It has its own unique characteristics and is especially suitable for users who have higher requirements for filtration of viscous materials. |

Optional parts for filter presses

Automatic filter press with drip tray

There are two plate shifters installed under the filter press plate. During the filtration process, the two-plate shifter is in a closed state, which can guide the dripping liquid and washing water during filtration to the water collector on the side. After filtration, open the two-plate transfer machine to discharge the filter cake.

Automatic filter press with conveyor belt

The belt conveyor is installed under the filter press plate and is used to transport the filter cake discharged after the filter press plate is opened. This device is suitable for projects where it is inconvenient to build the base layer. The cake can be delivered to a designated location, reducing a lot of labor.

Automatic filter press with filter cloth cleaning system

It is an ancillary equipment for the filter press, installed above the beam, and has an automatic walking function. Through the valve switch, high-pressure water (pressure up to 13Mpa) automatically cleans the clothes.

Specification

Manufacturing plant

Junyi series filter presses include plate and frame filter presses, chamber filter presses, membrane filter presses, cast iron filter presses, stainless steel filter presses, high temperature and high pressure filter presses, automatic self-cleaning filter presses, and automatic plate pullers. Filter press, one-time pull filter press, sealed filter press, circular filter press, various filter cloths, filter plates, related belt conveyors, belt shifters, and mud storage hoppers. We can customize filter presses according to customer requirements, such as different materials (the frame is made of stainless steel, PP board, spray plastic), different sizes, other special requirements for special filtrate such as volatile, toxic, irritating, odor or corrosiveness, etc. .

VIEW MORE

You may like

-

Alcove filter press factory well glass plate, fiberglass filter plate

-

Cement sludge dewatering circular filter press with plunger pump

-

Ceramic round chamber filter press with favorable price automatic customized filter press

-

Machine builder’s automatic membrane PP filter press for breweries

-

Refinery Edible Oil Biodiesel Pressure Leaf Filter

-

Solid-liquid separation filter press for wastewater treatment

-

High pressure reinforced polypropylene filter press PP filter plate

-

Multi-layer stainless steel plate filter media

-

Oil wine clay ceramic automatic filter press concave plate filter press chamber filter press

-

Stainless steel plate filter press for 100 liters of beer and wine

Other Products

-

$4000.00 - $4560.00 / set

$4000.00 - $4560.00 / set -

$1.00 - $1.50 / piece

$1.00 - $1.50 / piece -

$480.00 - $520.00 / piece

$480.00 - $520.00 / piece -

$1100.00 / set

$1100.00 / set

Related Search

membrane filter press

high quality nylon liquide cartridge filter suppliers

high quality mobile food cart for snacks with designers

high quality hepa filter h14 suppliers

high quality electric water pump motor price in pakistan

high quality solar hot water

high quality donaldson hydraulic filter

high quality hydraulic oil press brake

high quality air intaking filter

high quality diesel boiler feed water pump suppliers