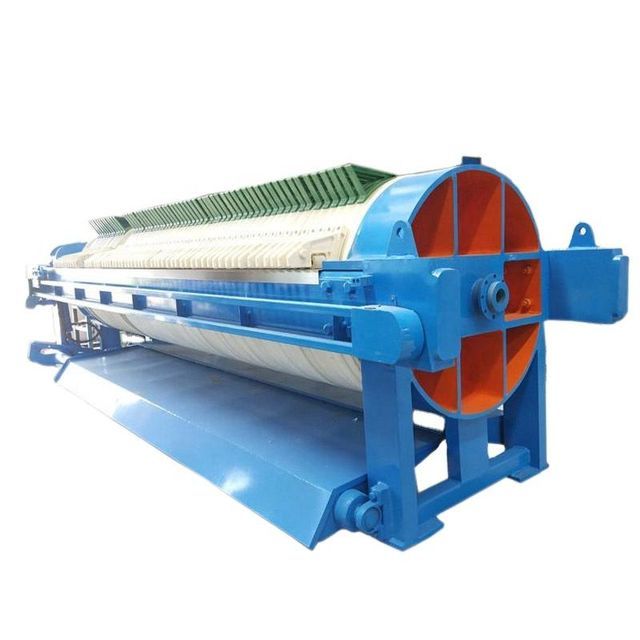

Cement sludge dewatering circular filter press with plunger pump

-

Supplier: Shanghai Junyi Filter Equipment Co.,Ltd -

Region: Shanghai, China -

Contact: Ms Susana Wang -

Price: $4560.00 / 1 - 4 sets

$4300.00 / 5 - 9 sets

$4000.00 / >=10 sets -

Min. Order: 1 set

Product details

| Filter plate size: | 800*800mm | Mechanical test report: | if |

| payment terms: | L/C, Western Union, T/T, MoneyGram | Cake Thickness: | 30/35/40 mm |

| Automatic: | automatic | Applicable industries: | Manufacturing plants, food and beverage plants, energy and mining |

| application: | Water treatment industry | Exhibition Hall Location: | Egypt, Canada, United States, Vietnam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, Mexico, Russia, Thailand, Malaysia |

| weight: | 1480 kg | product name: | Round Clay Filter Press |

| strength: | 2.2KW-7.5KW | Packaging Details: | The beams and frames are wrapped with plastic ropes, and the components and electrical parts are packed in wooden boxes. |

| Voltage: | client needs | Function: | Liquid-solid separation |

| Core components: | PLC, motor, pressure vessel | capacity: | 50-200 tons/day |

| Keywords: | Clay filter press | Video factory inspection: | if |

| Marketing Type: | New Products for 2020 | Origin: | China Shanghai |

| brand: | Junyi | type: | Automatic filter press |

| Supply capacity: | 10 sets per month | Dimensions (L*W*H): | custom made |

| port: | Shanghai Port | Specification: | Plate and frame filter press experiment |

| Core component warranty: | 1 year | Package Preview: | |

| Health status: | new | Warranty: | 12 months |

| Filter area: | 50-500 sqm |

introduce

| High pressure round filter press for clay/ceramics/kaolin/bentonite | |

| feature |

Its high pressure is 1.0-2.5Mpa, and it has the characteristics of high filtration pressure and low moisture content of filter cake.

|

| application | It is widely used in yellow wine filtration, rice wine filtration, stone wastewater, clay, kaolin and building materials industries. |

Technical Parameters

+

|

Model |

Filter area (square meters) |

Plate size(mm) |

Cavity volume(large) |

Number of plates(Item) |

Filtration pressure(MPa) |

|

XAMY30/φ800-25 |

thirty |

φ 800 |

377 |

thirty |

1.0 / 2.0 |

|

XAMY40/φ800-25 |

40 |

499 |

40 |

||

|

XAMY50/φ800-25 |

50 |

621 |

50 |

||

|

XAMY60/φ800-25 |

60 |

750 |

60 |

||

|

XAMY80/φ800-25 |

80 |

1200 |

80 |

Working Principles

The working principle of the filter press: when the mixed liquid flows through the filter cloth, the solids are retained on the filter cloth and accumulate into a cake, and the clear liquid without solids will permeate out of the filter cloth.

Filter Cake

transportation

Connection Diagram

business card

VIEW MORE

You may like

-

Alcove filter press factory well glass plate, fiberglass filter plate

-

Durable, high quality water filtration membrane filter press with cloth cleaning drip tray

-

Ceramic round chamber filter press with favorable price automatic customized filter press

-

Machine builder’s automatic membrane PP filter press for breweries

-

Refinery Edible Oil Biodiesel Pressure Leaf Filter

-

Solid-liquid separation filter press for wastewater treatment

-

High pressure reinforced polypropylene filter press PP filter plate

-

Multi-layer stainless steel plate filter media

-

Oil wine clay ceramic automatic filter press concave plate filter press chamber filter press

-

Stainless steel plate filter press for 100 liters of beer and wine

Other Products

-

$9500.00 - $10000.00 / set

$9500.00 - $10000.00 / set -

$1.00 - $1.50 / piece

$1.00 - $1.50 / piece -

$480.00 - $520.00 / piece

$480.00 - $520.00 / piece -

$1100.00 / set

$1100.00 / set