Second-hand Haitian injection molding machine Standard injection molding machine Second-hand 330-ton servo motor

-

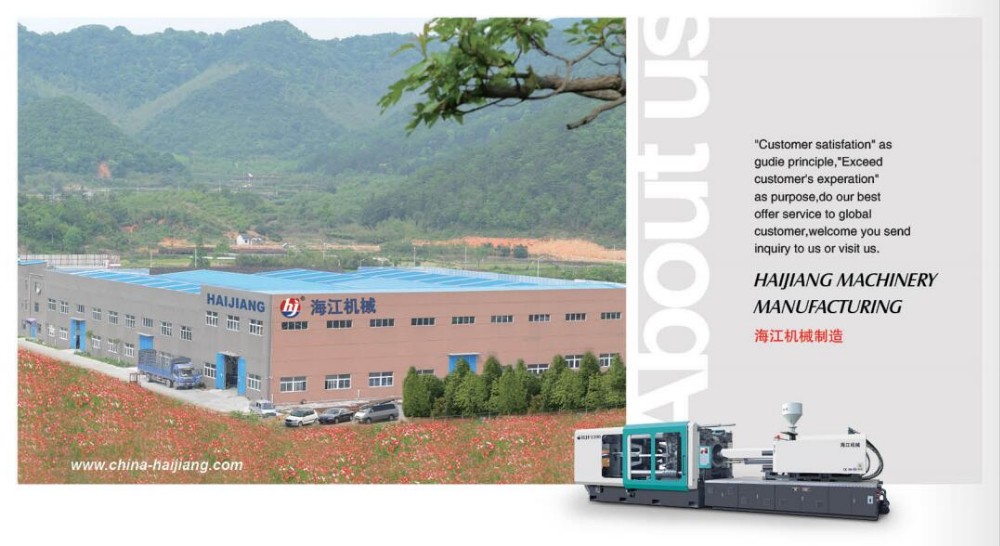

Supplier: Ningbo Haijiang Machinery Manufacturing Co., Ltd. -

Region: Zhejiang, China -

Contact: Mr Haijiang China -

Price: $7500.00 / 1 - 2 sets

$5000.00 / 3 - 4 sets

$3000.00 / >=5 sets -

Min. Order: 1 set

| Injection rate (g/s): | 240 g/s | brand: | Haijiang |

| Voltage: | 220V/380V/400V/415V | Number of injectors: | 7 |

| After-sales service provided: | On-site maintenance and repair services | automatic: | Yes |

| Plastic Type: | Thermoplastics | Tie rod spacing (height) (mm): | 600 mm |

| Mould height(mm): | 220 - 600 mm | style: | horizontal |

| Core components: | Bearings, motors, pumps, gears, PLCs, pressure vessels, engines, gearboxes | Tie rod spacing: | 610*600 |

| Machine Type: | Hydraulic | Weight (kg): | 8500 kg |

| Ejection force(kN): | 75 kN | Mechanical test report: | if |

| Screw speed (rpm): | 1 - 220 rpm | Applicable industries: | Hotels, manufacturing plants, machine shops, food and beverage plants, farms, restaurants, home use, retail, food stores, construction, energy and mining, food and beverage stores, advertising agencies |

| type: | Shoulder injection | Opening stroke(mm): | 585 mm |

| application: | Insert plastic products | Health status: | new |

| Screw aspect ratio: | 20 | Supply capacity: | 50 sets per month |

| Origin: | Zhejiang, China | Packaging Details: | Plastic film, wooden pad, shockproof iron-free chain, injection molding machine screw barrel |

| Plastic Processing: | PP, PC, ABS, PET, PVC, FRPP/PVC, PPR, EVA, HDPE, EPS, polystyrene, PE, LDPE, EVOH, HDPE/PP, ABS/PP, PE/PP, polylactic acid | Theoretical shot volume (cm³): | 847 cm³ |

| brand: | Haga | Video factory inspection: | if |

| Clamping force(kN): | 2900 kN | Ejector stroke(mm): | 150 mm |

| language: | Language customization | Start your trip: | 585 mm |

| Core component warranty: | 1.5 years | Key words: | Plastic machinery and equipment |

| Injection Weight(g): | 780 g | Exhibition Hall Location: | Egypt, Turkey, Indonesia, India, Russia, Thailand, Algeria, Bangladesh, Ukraine, Nigeria, Uzbekistan |

| Plasticizing capacity(g/s): | 780 | Screw diameter (mm): | 60 mm |

| payment terms: | L/C, Western Union, D/P, T/T | port: | Ningbo |

| model: | HJF290 | Warranty: | 2 years |

| Key selling points: | easy to use | Tie rod spacing (width) (mm): | 600 mm |

| Power (kW): | 11 kW |

Second-hand Haitian injection molding machine Standard injection molding machine Second-hand 330-ton servo motor

HaijiangWe supply various types of injection molding machines from 50T to 3000T, including color chip machines, energy-saving injection molding machines, gear machines, double-clear color injection molding machines, bakelite injection molding machines, PET preform injection molding machines, quantitative pump and variable pump injection molding machines, PVC pipe fittings injection molding machines, injection molding machine screw barrels, etc.

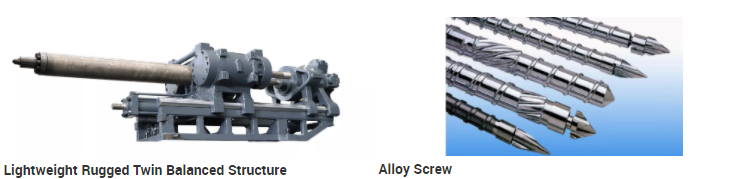

1. Features of Haijiang injection molding machine:

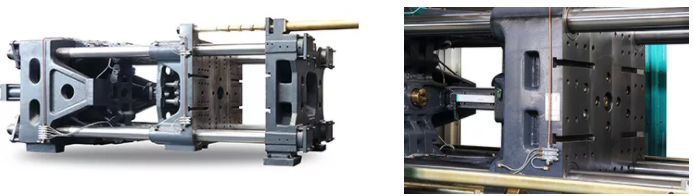

→ Wider tie rod spacing

→ Center clamping structure

→ Famous components

→ Use servo motor to save energy

→ Low noise, fast response

→ High precision, stability, and long life

→ T-slot clamp

→ Extensive range of spare parts

→ More favorable prices

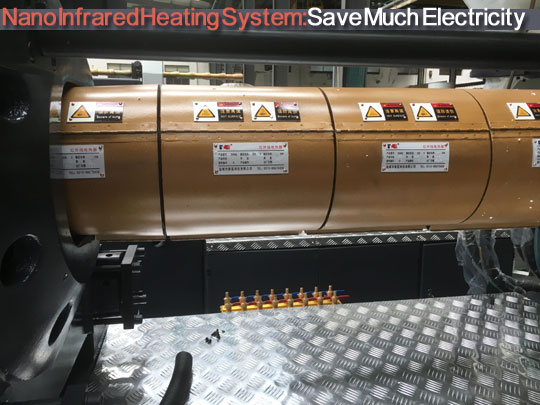

Injection unit:

1.) High-quality linear motion guides ensure smoothness and accuracy of the injection process

2.) High-speed and high-pressure injection structure can increase the injection speed

3.) Double nozzle cylinder ensures a more uniform and stable structure

4.) Screw barrels specially designed for various instruments

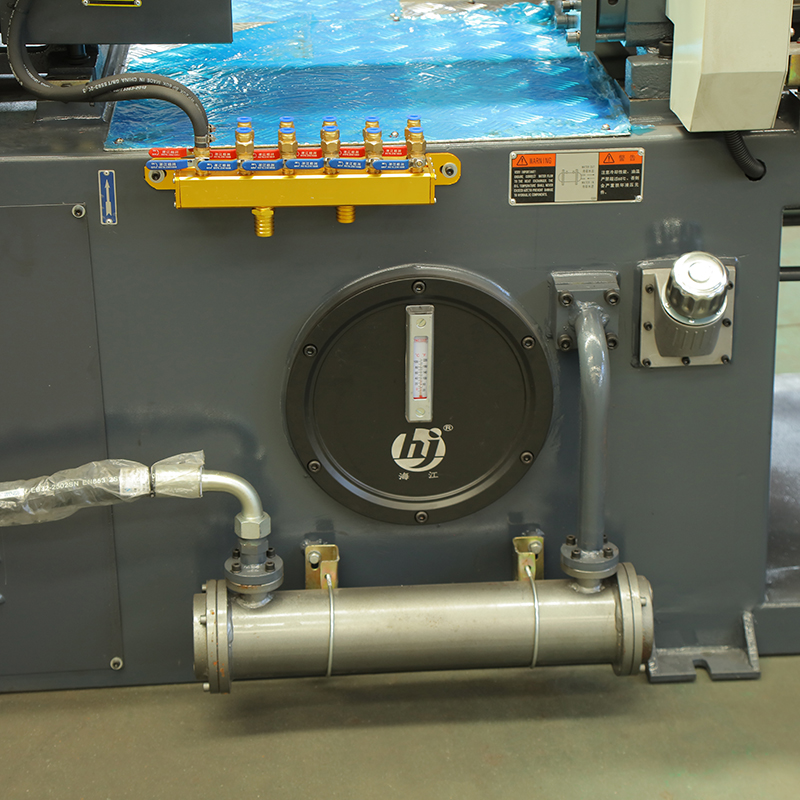

Hydraulic system:

1.) Dual proportional compound valve controls system pressure and flow, sensitive and stable

2.) Imported high-quality pump, low noise, long life and stable performance

3.) Optional world-renowned brand servo hydraulic system, lower noise and better energy saving effect

4.) The servo system has precise feedback control of pressure and flow, with higher sensitivity

5.) High-performance hydraulic valve, less failure, fast switching, easy maintenance

6.) Low-pressure mold protection system, more suitable for precision molds

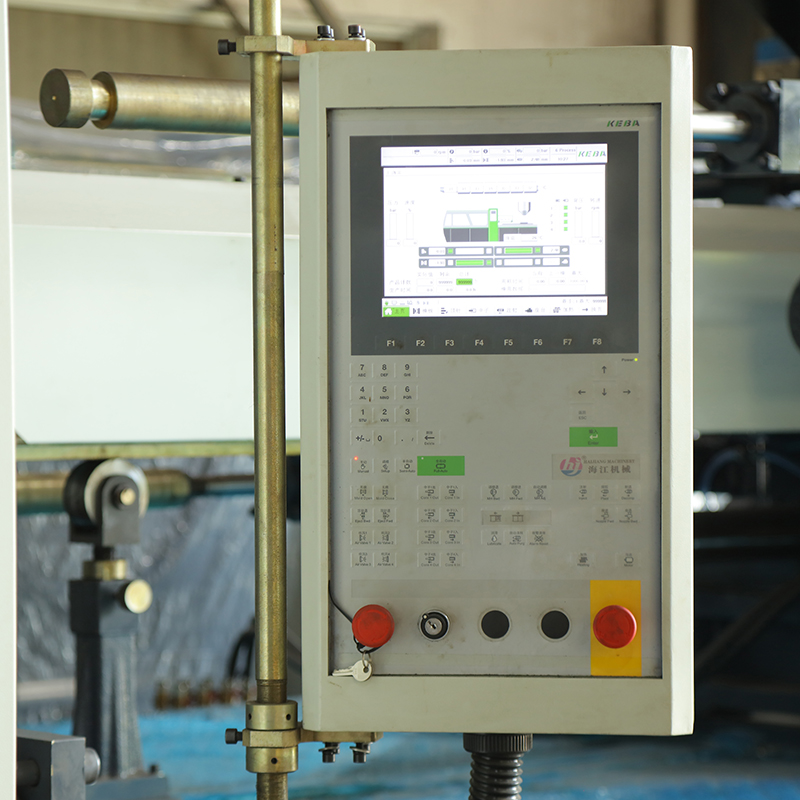

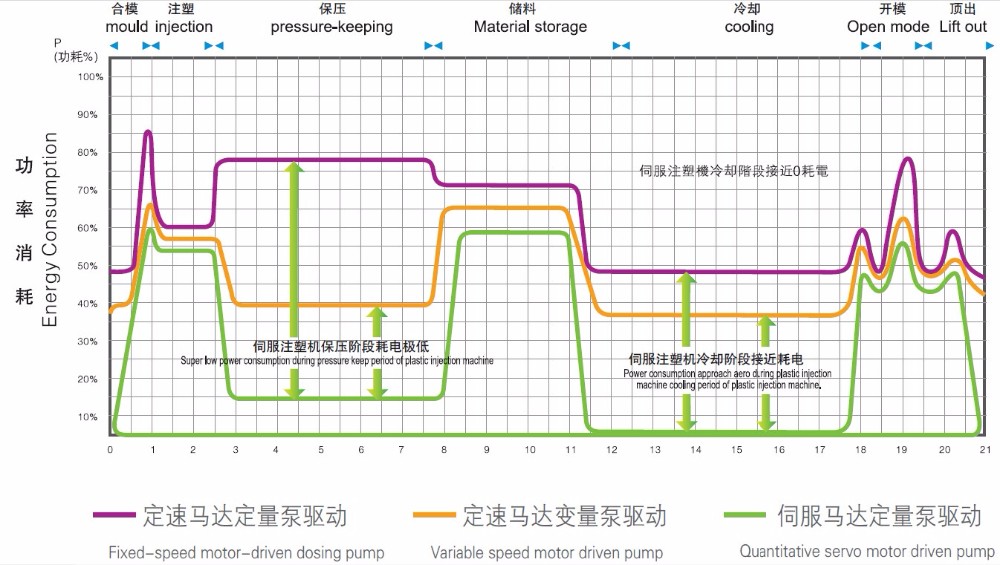

Servo controller part:

1.) The high-precision control servo system can accurately control the pressure, speed and position of the machine, ensuring the precise repeatability of injection measurement with an error of <0.3%

2.) Highly sensitive response Since the motor vector is precisely matched with the controller, it only takes 0.5 seconds to input the value from 0 to the maximum. Compared with traditional hydraulic injection molding machines, the HJS series is faster, has a shorter cycle time and higher production efficiency.

3.) Low noise Compared with traditional quantitative pumps and variable pump systems, the noise is reduced by 1/10 under normal use, which is more suitable for closed dust-free workshops

4.) Energy saving: The overall efficiency of the machine is 10% higher than that of ordinary models, the driving capacity is 18% higher, and it can save energy by 40-80%, achieving first-class energy saving effect.

5.) Water cooling saving system status prevents high voltage upload without any power output, thus saving water cooling

2. Injection molding machine parameters:

|

Specification |

HJF290 |

|||

|

Screw Type |

A |

Second |

C |

|

|

Screw diameter |

Millimeters |

55 |

60 |

65 |

|

Screw aspect ratio |

Aspect Ratio |

23.1 |

twenty one |

19.3 |

|

Injection volume (theoretical value) |

Cubic centimeters |

712 |

847 |

994.9 |

|

Injection weight (PS) |

G |

648 |

779.9 |

905 |

|

Injection rate |

g/s |

210 |

240 |

270 |

|

Injection pressure |

MPa |

205 |

168 |

143 |

|

Screw speed |

Rotating speed |

0~180 |

||

|

Clamping force |

Thousand Bulls |

2900 |

||

|

Opening and closing stroke |

Millimeters |

585 |

||

|

Tie rod spacing |

Millimeters |

600*600 |

||

|

Maximum mold height |

Millimeters |

600 |

||

|

Minimum mold height |

Millimeters |

220 |

||

|

Ejector stroke |

Millimeters |

150 |

||

|

Injector tonnage |

Thousand Bulls |

75 |

||

|

Maximum pump pressure |

MPa |

16 |

||

|

Pump motor power |

kilowatt |

thirty |

||

|

Heater power |

kilowatt |

15 |

||

|

Machine size (length*width*height) |

rice |

6.0*1.6*2.1 |

||

|

Machine weight |

television |

8.5 |

||

|

Fuel tank capacity |

large |

570 |

||

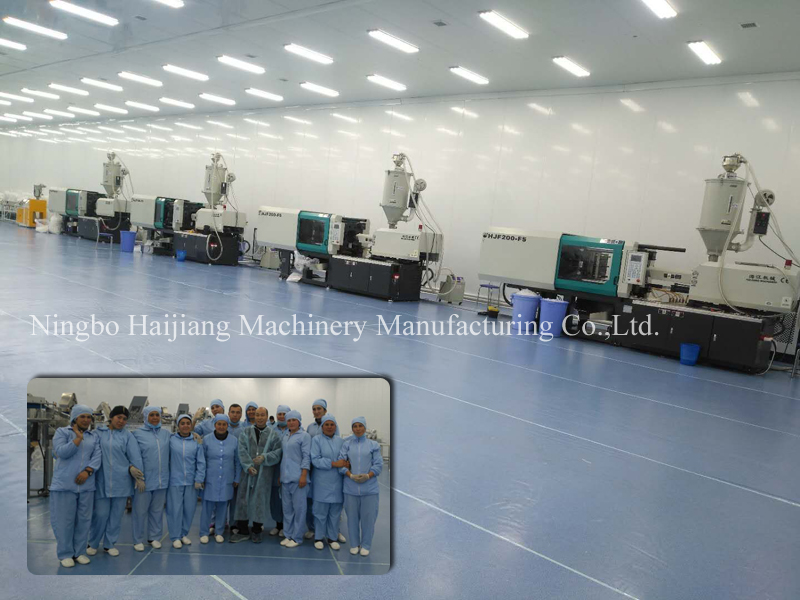

3. Injection molding machine in workshop:

4. Injection molding machine photos

4. Auxiliary equipment:

5. Haijiang Injection Molding Machine Exhibition

6. Packaging and delivery of Haijiang injection molding machines

7. Injection molding machine certification

FAQ

Q1. How long is the warranty period for plastic injection molding machines?

A1: 18 months in total, including machine platen, base, injection unit, clamping unit.

Question 2: Can you send engineers overseas to install machines and train customer workers?

Q2: Yes, we will send engineers to customer factory to install machines or train customer workers. Within one week, totally free. After one week, $150 per day

Q3: How many spare parts will you prepare for customers?

A3: Spare parts include: mold clamp, long and short nozzles, heating belt, wrench, switch, thermocouple, operation manual, tool box, lubricating oil, seal, filter, etc.

Q4: For the computer system, besides English, you can also change other languages, such as French, Spanish, Arabic, Russian.

A1: Yes, please tell us the language you need when you place an order. The standard languages are English, Japanese, Chinese, Korean.

Q5: Can you help us change the power supply? For example: we need three-phase 220V 60HZ

A5: When you place an order, please write it clearly. Then we will change the electrical system for you.

Q6: If I need green machine, can you make it for us?

Q7:Yes,please give us the color sample.So we can make it for you.

-

Highshine 250 Ton Servo Injection Molding Machine Trash Can Making Machine Maquina Inyectora De Plastico Precio

-

Fully automatic new horizontal PPR electric EPS polystyrene chair PC PVC PP PET preform plastic injection molding machine

-

Plastic Paint Bucket Container Box Making Machine Plastic Turnover Box Injection Molding Machine Plastic Fruit Basket Molding Machine

-

Low Price Used Haitian 120 Tons SA1200 Injection Molding Machine

-

metal injection molding china powder metal parts Precision metal works MIM parts factory medical instrument Door Lock Cylinder

-

Used high quality Japan NISSEI 7 tons small all electric injection molding machine

-

2021 Hot Sale Desktop Plastic Injection Molding Machine Small Injection Molding Machine

-

Wholesale plastic manual benchtop mini injection molding machine for making plastic parts

-

Injection Molding Machine for Disposable Infusion Set Infusion Set Production Line

-

Mini Small Benchtop Plastic Injection Molding Machine for Small Small and Laboratory Use

Other Products

-

$7000.00 - $7500.00 / set

$7000.00 - $7500.00 / set -

$4300.00 - $4600.00 / set

$4300.00 - $4600.00 / set -

$4500.00 / set

$4500.00 / set -

$49500.00 / set

$49500.00 / set -

$10000.00 / set

$10000.00 / set