Factory price high quality shoe upper making machinery 7 claw hydraulic automatic shoe toe machine

-

Supplier: Guangdong Tenghong Machinery Technology Co., Ltd. -

Region: Guangdong, China -

Contact: Ms Miss Wei -

Price: $8800.00 / 1 - 4 sets

$7500.00 / >=5 sets -

Min. Order: 1 set

Product details

| Function: | Save 100 sets of shoe styles | application: | Leather/Pu/Sports Shoes Manufacturing |

| Core components: | Motor, Pump | Packaging Details: | Cling film + bubble pearl film + wooden box |

| Video factory inspection: | if | Advantages: | High efficiency |

| Keywords: | Seven claws toe cap machine | Warranty: | 1 year |

| Automatic: | Semi-automatic | Health status: | New |

| Mechanical test report: | if | type: | Hydraulic shoe machine |

| Dimensions (L*W*H): | 1700*1000*1950mm | strength: | 2.2 kW |

| Core component warranty: | 1 year | Production capacity: | 800-1000 pairs/10 hours |

| Supply Ability: | 500 pieces per month | feature: | Hydraulic |

| Name: | 7-claw hydraulic automatic toe cap machine for upper production | Brand Name: | Teng Hong |

| Payment Terms: | wire transfer | Clamp type: | 7 Claws |

| pressure: | 50 kg/cm2 | Applicable industries: | Manufacturing plants, shoe factories, shoe industry |

| Origin: | Guangdong, China | Keywords: | Shoe production machine |

| Voltage: | 380 volts | Marketing Type: | Ordinary products |

| usage: | Toe Cap Machine | weight: | 1160 |

| Package Preview: | Exhibition Hall Location: | Türkiye, India | |

| application: | All types of shoes |

+

|

Automatic glue toe lasting machine

Hydraulic automatic upper gluing machine TH-N737MA shoe making machine

Product Description

feature:

1. Hydraulic operating system.

2. Each set of pliers can be set to automatic pulling or manual operation.

3. This machine is suitable for the heels of shoes with a heel height below 180mm, and the back of general midsoles and soft-soled shoes.

4. This machine is equipped with a micro switch for the knotting height, which makes the machine easy to adjust and accurately positioned.

Packaging and Shipping

a. The packaging will use standard wooden boxes to ensure that the items are not damaged.

b.Shipment is confirmed once the order is confirmed.

Company Information

Guangdong Tenghong Machinery Technology Co., Ltd. was established in 1998 and is located in Houjie Town, Dongguan City, Guangdong Province, China, a world-renowned shoe production base.

We specialize in the production of various toe machines, heel machines, side machines and heel machines and sole machines. At the same time, we also cooperate with other brands, such as Atom cutting machines and Camoga leather machines, embossing machines and other related shoemaking machinery. We have a professional production team, high-quality suppliers, experienced maintenance and R&D teams. We have our own warehouse, covering an area of about 5000 square meters. We provide high-quality machinery and perfect after-sales service at reasonable prices.

We can provide all the equipment needed for a shoe factory. Whatever shoemaking machine you need, please contact us.

Tel: +86 13926855520 Ms. Wei

Tel:+86 13925700309 Milly

Contact number: +6012-3783843 / +86 13925700309

application:Shoe Factory

Packaging and shipping: standard packaging

|

+

+

|

Toe Upper Machine

|

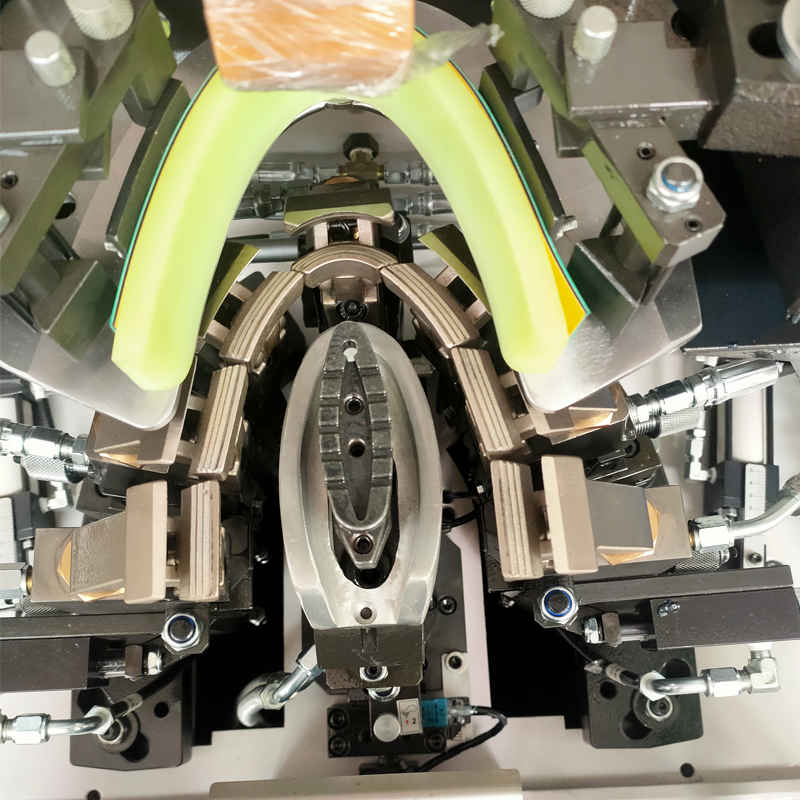

Seven claws

|

Electrical box

|

+

+

+

+

+

|

Fully hydraulic operating system.

The double-track pliers are equipped with 7 finely adjustable and quickly replaceable pliers.

The left and right last claws automatically turn inward to increase the perfection of the inner upper.

Each set of pliers (left and right) can be set to automatic pulling or manual pulling to avoid pulling only one side of the shoe uppers of different materials.

The upward stroke of the last stay can be adjusted by a knob on the outside of the machine.

The last support has a two-step upward movement function, which cooperates with the heel support movement to prevent the last from slipping.

The width of the applicator can be quickly adjusted to different shoe sizes to achieve the perfect glue dot on the insole.

The toe push mechanism adopts an adjustable two-stage pressure design. During the movement of the initial pressure, two modes (pressure control or position control) can be set to obtain the best operation.

The forward speed of the wiper can be controlled steplessly.

Standard equipment: Auxiliary wiper mechanism, auxiliary side thruster mechanism and toe projector mechanism.

|

+

|

Model

|

Dimensions (length, width, height)

|

Packing size (length, width and height)

|

weight

|

Production

|

strength

|

Voltage

|

|

TH-737B

|

1700*1000*1950

|

1800*1160*2100

|

1160 kg

|

1600 pairs/8 hours

|

2.7 kW

|

380 volts

|

Shoe machine application

+

Shoe Manufacturing Process

+

VIEW MORE

You may like

-

Refurbished second-hand Chenfeng hydraulic shoe toe and heel machine

-

Small Production Automatic Shoe Cement Toe Last Shoe Making Machine Price

-

Automatic Leather Shoes Upper Boots Hot Press Forming Machine

-

9 pliers computer memory control automatic servo gluing back upper mechanism shoe machinery

-

Shoe mold making machine automatic hydraulic computer consolidation shoe toe heel machine

-

Toe Lasting Machine Price Vending Machine Shoe Automatic Lasting Machine

-

Hydraulic Automatic Sports Shoes School Shoes Back Knot Shoe Making Machine

-

Automatic Lasting Machine Price Lasting Machine Spare Parts Lasting Machine

-

Shoe making machine Pneumatic snow boot toe forming machine

-

Factory price hot melt glue shoe last machine automatic shoe last sticking machine

Other Products

-

$21000.00 - $22000.00 / piece

$21000.00 - $22000.00 / piece -

$445.00 - $475.00 / piece

$445.00 - $475.00 / piece -

$29576.00 - $31500.00 / piece

$29576.00 - $31500.00 / piece -

$3200.00 - $3500.00 / piece

$3200.00 - $3500.00 / piece

Related Search

high quality garbage bag making machine

high quality sugar cube making machine

factory competitive price and high quality!

best price with high qualiti ku lnb suppliers

high qualiti rubber shoe cover suppliers

new designed shoe making machinery

high quality electric water pump motor price in pakistan

high quality mosfet portable welding machine price

high quality 5l 10l 20l 50l rotary evaporator price

high quality handle making machine