cold feed rubber extruder making machine

-

Supplier: Foshan Jct Machinery Co., Ltd. -

Region: Guangdong, China -

Price: $2000.00 /set -

Min. Order: 1 set

| Type: | Rubber Kneader; | Brand Name: | JCT; |

| Voltage: | 220V, 380V, 440V; | Packaging Detail: | Standard Export Cases, Standard Neutral packing, wooden package; |

| Certification: | ISO9001,CE; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram,CASH; |

| Discharge mode: | Bottom pumping, hydraulic tilting, screwing; | Supplier type: | kneader manufacturer; |

| Speed control: | Inverter for frequency control; | After-sales Service Provided: | Video technical support; |

| Power(W): | 0.75KW-150KW; | Materials: | SS304 + Q235-B; |

| Condition: | New; | Port: | shenzhen, guangzhou, foshan; |

| Weight: | 200kg to 7000kg; | Supply Ability: | 100 Set/Sets per Year kneader; |

| Blades mode: | Two sigma blades; | Speed: | Slow/ quick blades = 28/ 42 rpm; |

| Vacuum degree: | -0.098Mpa; | Motors: | Anti-explosion; |

| Heating mode: | Jacketed oil heating; | Warranty: | 1 Year; |

| Place of Origin: | Guangdong China; | Dimension(L*W*H): | 0.8m *0.5m *1m -1.6m *1m *2.5m; |

cold feed rubber extruder making machine

1. Instruction:

1). Kneading machine does very well in mixing, kneading, crushing and dispersing for high-viscosity liquid materials, with no dead point.

2). Two sigma or Z-type blades.

3). Equipped with inverter for frequency control.

4). Vacuum and high pressure are available.

5). The cylinder is opened hydraulically.

6). Discharge mode: Hydraulic tilting, Bottom pumping,or Screwing.

7). With jacket outside of the cylinder, for heating or cooling.

8). Heating mode: Hot oil, Electric or Steam/

9). All the parts that contact with material are made of stainless steel.

10). Widely used in high viscosity sealant, silicone rubber, CMC, adhesive, also used in batteries, ink, pigments, dyes, pharmaceuticals, resins, plastics, rubber, cosmetics ect.

2. JCT cold feed rubber extruder making machine applies for:

1) Chemicals Industry:

Sealant, rubber, glue/ adhesive, paint, dye, CMC, battery, pigment

2) Food Industry:

Bubble gum, chewing gum, soft candy, cheese etc.

3) Pharmaceutical:

Some medicines and medical materials.

4) Cosmetics industry

5) According to stattistics, JCT vacuum kneaders are most widely used in making:

Silicone sealant, Hot melt adhesive, Bubble/ chewing gum, Silicone rubber & Compound rubber, CMC

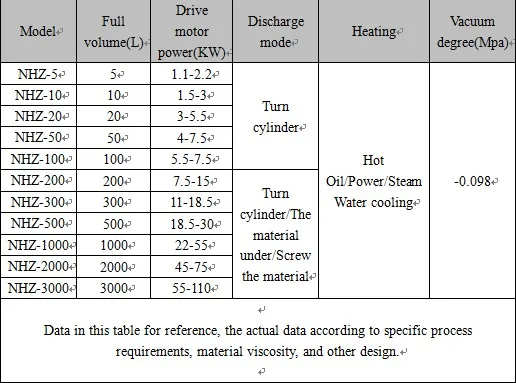

3. The Technical parameter of cold feed rubber extruder making machine:

4. Pictures of the cold feed rubber extruder making machine:

Some of the Kneaders Making Records in JCT Factory

The Kneaders Samples of JCT Machinery Co., Ltd.

Different Kneader Paddles (can be designed as other types by clients' reqiurements)

Packaging Detail: Wooden package & container. (Can be arranged as clients's requirements). JCT vacuum kneader

Delivery Detail: 20 - 30 days. JCT kneader

1. Company Introduction

1) Foshan JCT Machinery Co., Ltd. (www.gdjct.en.alibaba.com)

2) Professional manufacturer for chemical machineries, with 13 years' rich experience in this field.

3) JCT specializes in all kinds of reactors, mixers, kneaders, dispersers and some filling machines and extruders etc. And the machines are widely used in all kinds of adhesives, resins, rubbers, paints, sealants, chemicals, emulsions and some food and pharmaceutical industries.

4) JCT Machinery Co., Ltd was formally set up at 2003, but the origianl entrepreneur team are all very professional engineers who were with 20 years' experience.

5) JCT's main markets: China, Europe, Africa, Middle East, South America and South Asia, we can sell machines to anywhere as long as it needs.

2. Certificates

3.Our Clients

1. Warranty and After-sale Services

1) 18 months' free of charge warranty for all of our machines except of the pipes, valves, pumps etc.

2) 24 hours technical support by email, skype, mobile-phone.

3) Calling or door-to-door service.

4) Engineers are available to overseas for technical support or producing guidance.

5) Original manufacturers' price for quick-wear parts of our machines.

2.Contact Informatioin

-

High-quality practical enamel badge manufacturing machine automatic visual spray glue machine

-

Rubber tube/rubber belt/rubber profile extruder

-

Hot selling 65mm cold feed silicone rubber extruder

-

Rubber band making machine/natural rubber band production line and technical support

-

Rubber extrusion vulcanization production line Machine for making EPDM rubber profiles

-

Rubber Screen Extruder For Rubber Filtration

-

Technical Support for Elastic Band Making Machine/Apron Production Line

-

100-1000kg/h Masterbatch Machine Plastic Filling Extruders with Twin Screws for Masterbatch Production Line

-

Made in China Supply UCT Shape Extruded Window Door Auto Foam EPDM Rubber PVC Seal Strip Making Machine

-

OEM Rubber Band Product Manufacturing Machinery Extrusion Insulation Tube Rubber Hose Production Line Rubber Preform Extrusion Machine