Four Columns Hydraulic Die Cutting Machine / Clicker Press

-

Supplier: Guangdong Honggang Intelligent Equipment Co., Ltd. -

Region: Guangdong, China -

Contact: Ms Mandy Chen -

Price: $3900.00 /set -

Min. Order: 1 set

| Color: | Blue; | Columns: | four; |

| Place of Origin: | Guangdong China; | Product name: | Leather Cutting Machine; |

| After-sales Service Provided: | Field maintenance and repair service; | Payment Terms: | L/C,T/T,Western Union; |

| Packaging Detail: | cutting machine 1,Standard export wooden case with plastci film. 2,as customer's request.; | Working mode: | cutting by die/mould; |

| Cutting area: | 1220*610mm or 1600*610mm or Costomize; | Port: | guangzhou,shenzhen; |

| After-sales Service Provided: | Engineers available to service machinery overseas; | Cutting force: | 30tons;25-100tons or Costomize; |

| Brand Name: | HONGGANG; | Stroke: | 50-240mm; |

| Warranty: | 1 Year; | Suitable for material: | rubber/EVA Foam/fabric/paper/plastic and so on; |

| Supply Ability: | 100 Set/Sets per Week cutting machine; | Feeding side: | automatic,double,or as request.; |

Four Columns Hydraulic Die Cutting Machine / Clicker Press

Watch on youtube:

hydraulic cutting machine for multi-layer materials cutting video:

https://www.youtube.com/watch?v=LK0_k7blRDs

hydraulic cutting machine for foam materials cutting video:

https://www.youtube.com/watch?v=ceqEXQnFBWQ&index=1&list=PLZTnvjIksKDgVDj1Cd96ZheQwfuMG5mTG

hydraulic cutting machine for plywood materials cutting video:

https://www.youtube.com/watch?v=D36eBzjefCU

More cutting machine video on our youtube page:

https://www.youtube.com/channel/UCO-wTQeY0Hox4c4Gako8vAQ/videos

What Specification of our hydraulic cutting machine?

The working principle of the hydraulic cutting machine is down press to the mould,to cut material by dies / moulds.

1.The hydraulic cutting machine Cutting-Force:25ton--200Ton.

2.Hydraulic, manual simple operated,material precision 0.01mm,no burned.

3.Two Cylinders,Four Column.

4.Suitable to die cut all non-metal soft /half-soft materials.From manual to full automatic type.

5.Can make big cutting area: 2.3*1.3m or as required.

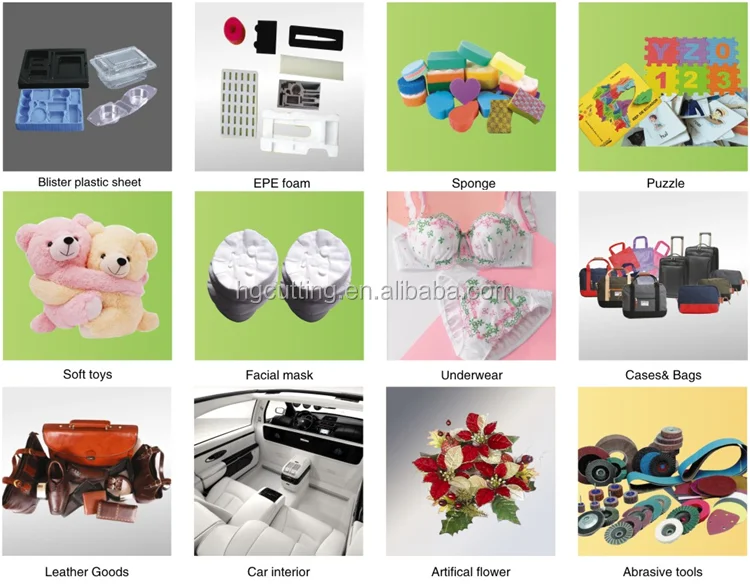

Mainly used for die cutting leather and leather products,plastic,rubber,sponge,foam,EVA,PVC,cardboard, paper products,fabric,home textiles,packaging materials,non woven,carpet,car cushion,felt,synthetic materials, and other non-metallic materials in various industries;Extremely suitable for cutting multiple layers of material at one time.

1. Technical Parameters

| Model.No~ | Cutting Force | Dimension (L*W*H) | Area of Work Table | Main Motor Power | Stroke Control Range | Net Weight |

| HG-a30T/63" | 30 Tons | 2330*1320*1260mm | 610*1600mm | 2.2kw | 50-160mm | 1900kg |

| HG-B30T/63" | 30 Tons | 2330*1320*1260mm | 610*1600mm | 2.2kw | 50-240mm | 2000kg |

| HG-B30T/48" | 30 Tons | 1950*1320*1260mm | 610*1220mm | 2.2kw | 50-240mm | 1900kg |

| HG-a40T/63" | 40 Tons | 2330*1320*1260mm | 610*1600mm | 4kw | 50-160mm | 2500kg |

| HG-B40T/48" | 40 Tons | 1950*1320*1260mm | 610*1220mm | 4kw | 50-240mm | 2400kg |

| HG-a50T/63" | 50 Tons | 2330*1320*1260mm | 610*1600mm | 4kw | 50-160mm | 2900kg |

| HG-B50T/48" | 50 Tons | 1950*1320*1260mm | 610*1220mm | 4kw | 50-240mm | 2800kg |

2. Features and Advantages

Features and Advantages | ||||||

| 1.Double-cylinders,four-columns,self-balancing connecting rod which can maintain equal pressure of each position. | ||||||

| 2.Series B machine has the long-stroke setting for adopt to the jumbo-size materials and high knife mould cutting. | ||||||

| 3.When the upper board pressure down and contact to the blade,automatically,it can cut slowly,so that there is no size error between the top and the bottom materials. | ||||||

| 4.The unique setting construction,combine with the cutting knife and cutting height which stroke simple and accurate. | ||||||

| 5.Central automatic lubrication systems can ensure precision and durability of the machine. | ||||||

| 6.More economical and 2 or 3 times improving producting capacity. |

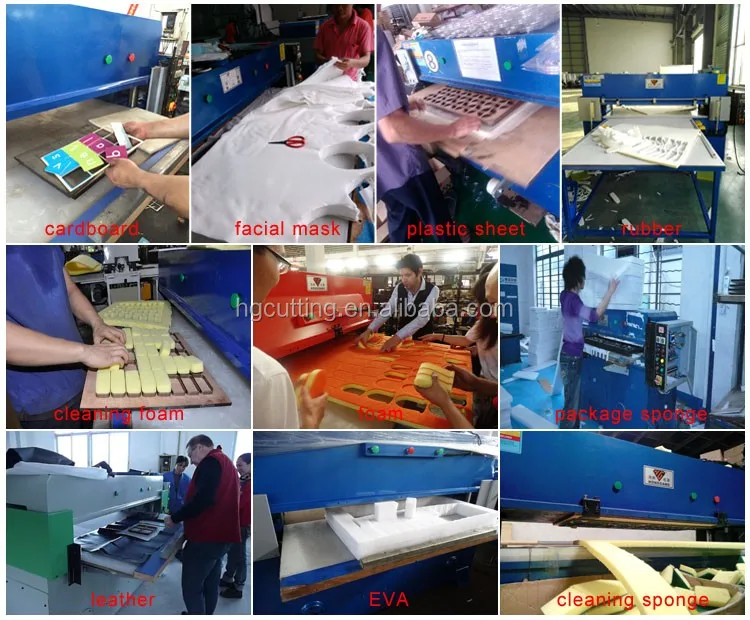

What Working of our hydraulic cutting machine?

3. the cutting-dies & PP board

We can according to your material,requirements,design the mould for you.

What Application of our hydraulic cutting machie?

The hydraulic die cutting machine is suitable to die cut all non-metal soft /half-soft materials, especially use for die cutting shoes,suitcases,bags,cases,seat covers,facial mash,soft toys,cleaning sponges,artifical flower,EPE,EVA,blister and abrasive tools.

4. The Hydraulic Cutting Machine Manufacturing Process:

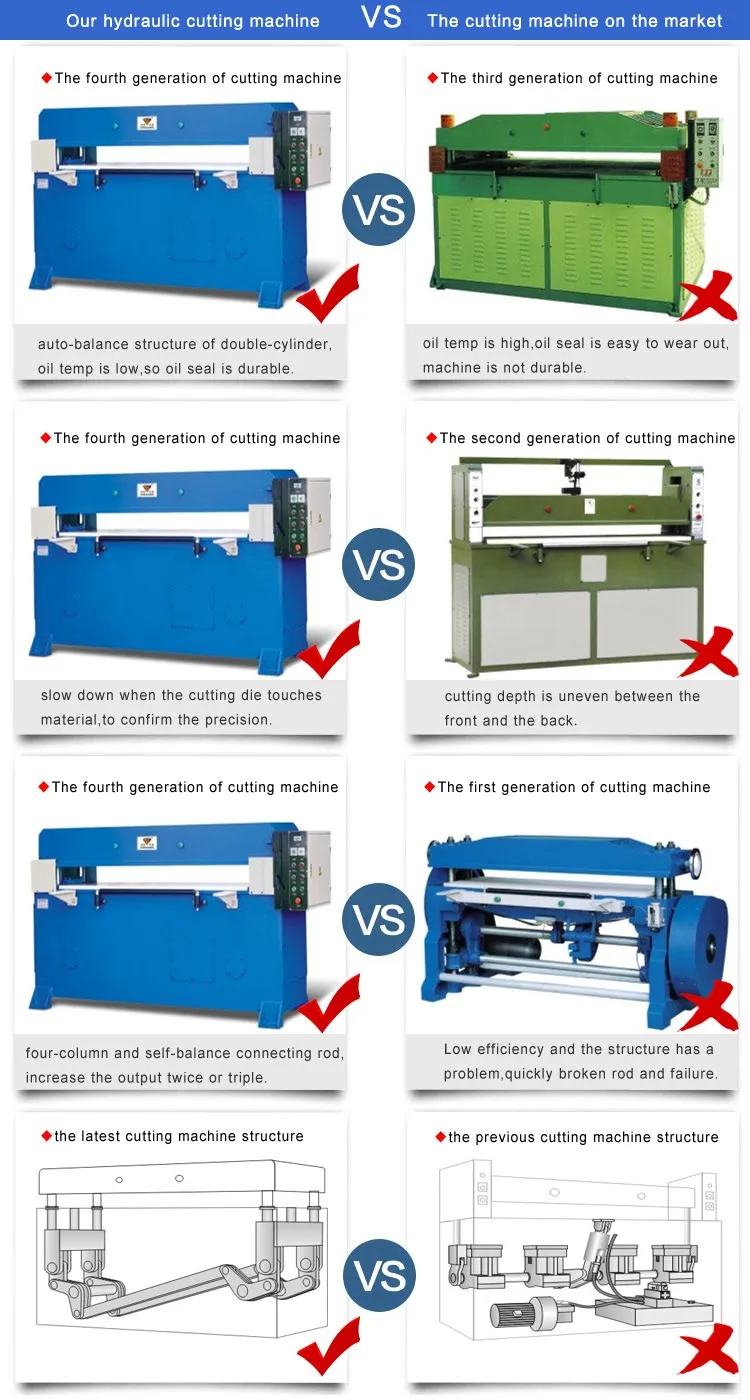

5.Compare the advantages of our machine:

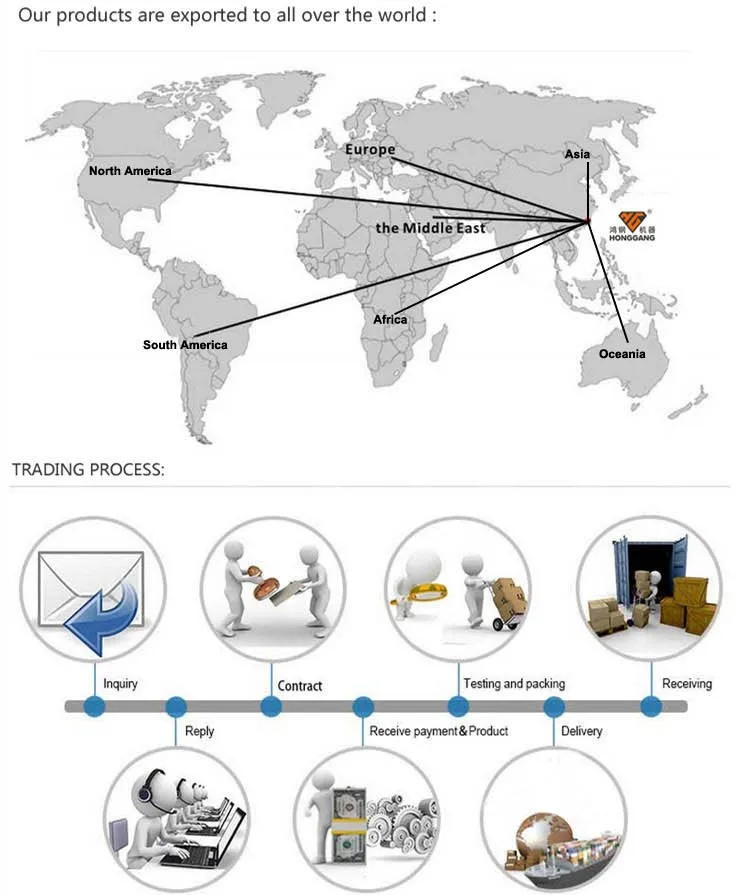

Trade Terms:

Trade term:FOB,CIF,EXW

Payment terms:T/T,Westem Union,PayPal,Escow,MoneyGram.

Payment Condition:30% deposit in advance. 70% balance before delivery.

Delivery time:5-15days working days after deposit.

Packing:Wooden case with plate.

Shipment:By Sea.

1. We are a factory, and the price is favorable.

2. We have strict QC system.

3. We offer a free after-sales warranty for 1 years;life-long maintenance service.

4. Our engineers are available to service machinery overseas.

5. Our machines have been sold to over 40 countries.

Company show

1)What's warranty of hydraulic cutting machine?

12 months Warranty

Life-long maintenance service for press cutting machine

2)What's your after-sales service?

Engineer available to serve machines over seas;

Email and calling service in working hour; 24 hours door to door in domestic.

3)Can we test the our material by your machine free?

Yes, please contact us to send your matrial.

4)How to confirm how much ton pressure is fine?

Always 1m knife line need about 5 ton pressure.

please send your drawing or product photo, we can help you confirm.

5)Can you make dies & PP boards?

Yes, just send your drawing or material.

PP board will come with machine to you.

6)Are you a factory or trading company?

We are a factory and manufacturer

Don't know how many ton you need?

Please contact us!

Don't know how the machine working?

Please contact us to see the video!

How to Contact Us?

If you are not sure if your material can be cut by this cutting machine,we want to know the product information:

| Material: | |

| Max. material width: | |

| Max. material thickness: | |

| Max.cutting length: | |

Send your Inquiry Details in the Below, Click "Send" !

we will reply within 24h!

-

-

Intelligent vision digital automatic marking and printing line drawing machine for uppers and soles

-

Factory price high quality shoe upper making machinery 7 claw hydraulic automatic shoe toe machine

-

Shoemaking machine automatic sole pressing machine double head hydraulic sole pressing machine

-

Injection Rubber Slipper Strap Making Machine

-

Hydraulic technology automatic heel machine

-

Tenghong TH-658A Hydraulic Computer Automatic Gluing Fully Automatic Side Heel Upper Machine

-

Customers praise the one-stop pneumatic bottom press machine

-

Fully automatic curtain hole punching machine

-

Fabric, Foam, Velvet Automatic Fabric Coating Machine Made in China

Other Products

-

$18500.00 / set

$18500.00 / set -

$120000.00 / set

$120000.00 / set -

$12000.00 / set

$12000.00 / set -

$3900.00 / set

$3900.00 / set