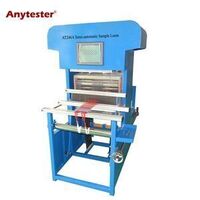

Single Yarn Sizing Machine Equipped With Yarn Tension Measuring Device And Yarn Breaking Detector With single spindle control

-

Supplier: Anytester (Hefei) Co., Ltd. -

Region: Anhui, China -

Contact: Mr Eric Qin -

Price: $8000.00 /set -

Min. Order: 1 set

| Machine Type: | Textile Tester; | Brand Name: | Anytester; |

| Heating method: | Steam heating or electric heating (optional); | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram; |

| Dimensions: | 3100*850*1750mm for 4 spindle machine; | Sizing speed: | 20~300m/min; |

| Condition: | New; | After-sales Service Provided: | Video technical support,Online support; |

| Packaging Detail: | Export Standard Wooden Case; | Weight: | N. T1000Kg. G.T 1100Kg for 6-spindle machine; |

| Motor power of heat circulation: | Approx.1.lKW; | Motor power of rotation frame: | 0.18KW per spindle; |

| Applicable yarn density: | 5~500tex, cotton, wool silk or chemical fiber; | Port: | Any China Seaport; |

| Material Capabilities: | as description; | Product: | Sizing Machine; |

| Place of Origin: | Anhui China; | Warranty: | 1 Year; |

| Supply Ability: | 200 Unit/Units per Year; | Certification: | ISO; |

AT240 Series Single Yarn Sizing Machine is suitable for yarn sizing of cotton, flax, silk, wool, synthetic filament, etc.

As the textile develops in the direction of small quantity, diverse kind and prompt delivery, so our company has developed AT240 Series Yarn Sizing Machine on the increasing requirements on product samples. It is widely used in the sampling in the industries including wool spinning, cotton spinning, colored woven and natural silk etc.

Independent control of each spindle, digital display

of tension index and digital display of speed of

rotating frame and counting of length. And rotating

frame storing 160 turns of yarn on it to increase the

drying time

single spindle control, the frequency controller

or steeples controller is used for cabbage

rotational motor in drying room. The yarn guide

cylinder is traced by the servo.

Motor

Grooved drum controlled by servo motor and

its rotation speed is automatically adjusted

according to the speed of rotating frame to

control the yarn tension

Grooved drum controlled by servo motor and its

rotation speed is automatically adjusted

according to the speed of rotating frame to

control the yarn tension

Equipped with yarn tension measuring

device and yarn breaking detector which

make the machine easy to operate and high

efficient.

History

Since 1982 with more than 20 years' experience

Warranty

Two Year Warranty for whole product

Training

Video and user manual for training

Onsite service

Installation and training service is available

Testing service

Free sample testing before order is available

Lead time

15 working days lead time for most product

-

Plush toy sofa cotton pillow fiber manufacturing and filling machine

-

Ear lanyard braiding machine head

-

Xuzhou Henghui Handle Rope/Shoelace Automatic Heading Machine

-

For sale wholesale price 2 in 1 pistols with handgun pistol grips

-

Cotton Waste Recycling Machine Automatic Wool Cotton Fiber Opener Wool Opener Fabric Recycling Machinery

-

YJ1000V high speed polyester thread texture machine

-

Easy To Use Automatic Infrared Positioning Laser Bag Opener 3520

-

robot making icn machine video carpet tufting kit

-

Fiber opener/wool opener/cotton fiber opener at best price and high quality

-

Fiber opener polyester cotton waste recycling loose machine pillow stuffed toy doll PP cotton opener price

Other Products

-

$18500.00 / set

$18500.00 / set -

$6500.00 / set

$6500.00 / set -

$2500.00 / set

$2500.00 / set -

$9000.00 / set

$9000.00 / set -

$5000.00 / unit

$5000.00 / unit -

$20000.00 / set

$20000.00 / set -

$25000.00 / set

$25000.00 / set -

$1500.00 / set

$1500.00 / set -

$1950.00 / set

$1950.00 / set -

$4300.00 / set

$4300.00 / set