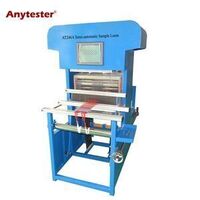

Batch-Type Low Temperature Carbide Furnace with Heat-resistant stainless steel pre-heating tube and quartz stopper

-

Supplier: Anytester (Hefei) Co., Ltd. -

Region: Anhui, China -

Contact: Mr Eric Qin -

Price: $20000.00 /set -

Min. Order: 1 set

| Size of pre-heating furnace: | diameter89*1200mm; | Condition: | New; |

| Place of Origin: | Anhui China; | Port: | Any China Seaport; |

| Temperature controlling accuracy: | 0.5%; | Connector: | diameter40 stainless steel corrugated pipe; |

| Steam source: | Steam generator with flowmeter to control pressure; | Package Preview: | ; |

| After-sales Service Provided: | Online support; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram; |

| Certification: | ISO; | Supply Ability: | 200 Unit/Units per Year; |

| Packaging Detail: | Export Standard Wooden Case; | Warranty: | 1 YEAR; |

| Temperature controlling mode: | Intelligent controller; | Size of working furnace: | diameter89*1500mm; |

| Brand Name: | Anytester; |

AT232B Batch-type Low Temperature Carbide Furnace consists of pre-heating tube, working furnace tube, steam generator and flow controlling system. The pre-heating tube has two heating sections and the working furnace tube has three heating sections. Pre-heat steam produced by steam generator, air or oxygen to 600℃ in the pre-heating tube and then enters into the working heating furnace tube through pressure-adjusting valve and flowmeter. The pre-heat tube is connected with the working furnace tube by a rapid-connection connector and they are horizontally laid in rank. The heating furnace for the working furnace tube is open-able and dischargeable, convenient to observe. There is stainless steel filtering screen in the pre-heating tube for uniformly heating gas.

1.Two-furnace structure;

2.Sheet metal bracket with electrostatic spraying plastics;

3.Heat-resistant stainless steel pre-heating tube and quartz stopper;

4.Mollite fiber open-able heating furnace and tube heating furnace;

5.Steam generator with the flow-meter to control pressure;

History

Since 1982 with more than 20 years' experience

Warranty

Two Year Warranty for whole product

Training

Video and user manual for training

Onsite service

Installation and training service is available

Testing service

Free sample testing before order is available

Lead time

15 working days lead time for most product

-

Low Price Carbonization Furnace Charcoal Making Machine

-

charcoal forming machine charcoal forming machine charcoal forming machine

-

Charcoal production equipment cost investment small economical small carbonization furnace smokeless carbonization furnace

-

Multifunctional carbonization furnace charcoal machine

-

Coco coconut shell charcoal carbonization furnace machine

-

Factory direct supply charcoal kiln wood chip carbonization machine carbonization furnace

-

China large capacity industrial smokeless wood chip carbonization furnace kiln

-

Large Capacity Log Biochar BBQ Charcoal Making Machine Price

-

Biomass carbonizer rotary kiln

-

Activated Carbon Manufacturing Factory Charcoal Making Machine Activated Carbonization Furnace For Sale

Other Products

-

$18500.00 / set

$18500.00 / set -

$6500.00 / set

$6500.00 / set -

$2500.00 / set

$2500.00 / set -

$9000.00 / set

$9000.00 / set -

$5000.00 / unit

$5000.00 / unit -

$25000.00 / set

$25000.00 / set -

$1500.00 / set

$1500.00 / set -

$1950.00 / set

$1950.00 / set -

$4300.00 / set

$4300.00 / set -

$10000.00 / set

$10000.00 / set