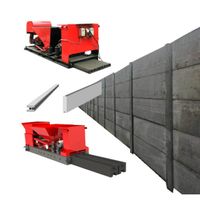

Prestressed concrete hollow core slab concrete hollow board making machine for use building houses

-

Supplier: Cangzhou ASC Toner Production Ltd. -

Region: Hebei, China -

Contact: Ms. Jessica Lin -

Price: $26000.00 /unit -

Min. Order: 1 unit

| Warranty: | 12 Months; | Supply Ability: | 20 Set/Sets per Month; |

| Automatic Grade: | Automatic; | Place of Origin: | china; |

| Steel diameter: | 12.7mm steel strand; | Voltage: | 380V/50HZ; |

| Port: | xingang,shanghai,lianyuangang,qingdao,shenzhen etc.; | Power(W): | 10.5kw; |

| Production Capacity: | 1.6m/min; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram; |

| Color: | Upon request; | Brand Name: | no; |

| Certification: | ISO9001, CE; | Max load: | 10.9m; |

| Max length: | 10.5m; | After-sales Service Provided: | Engineers available to service machinery overseas; |

| Type: | Semi-automation; | Main process: | Forming; |

| Features: | Prestressed; | Strength: | YG Wear Resistant Alloy; |

| No. of holes: | 8; | Application: | Building Materials Machinery; |

| Weight: | 3.9t; | Raw materials: | C30~C40 concrete; |

| Dimension(L*W*H): | 3.5*1.7*1.4m; | After-sales Service Provided: | No after-sales service,Online support,Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Video technical support; |

| Packaging Detail: | Neutral packing; |

Prestressed concrete hollow core slab concrete hollow board making machine for use bulding houses

Prestressed concrete hollow core slab

concrete hollow board making machine for use bulding houses

Thickness* Width | Total Power (KW) | productivity (m/min) | Max Length (m) | Maximum load capacity (kn/m2) | Steel Diameter | Number of steel used | Holes |

100*600 | 8 | 1.2-1.4 | 5.1 | 8.11 | 7mm | 5 | 6 |

120*600 | 8.5 | 1.2-1.4 | 6 | 8.86 | 7mm | 6 | 5 |

150*600 | 10.5 | 1.2-1.4 | 7.5 | 10.24 | 9.5mm | 5 | 4 |

180*600 | 10.5 | 1.2-1.4 | 9 | 16.16 | 12.7mm | 4 | 3 |

100*900 | 10 | 1.2-1.4 | 5.1 | 9.76 | 7mm | 10 | 10 |

120*900 | 14 | 1.2-1.4 | 6 | 8.86 | 7mm | 9 | 8 |

150*900 | 15 | 1.2-1.4 | 7.5 | 10.24 | 9.5mm | 10 | 6 |

180*900 | 15 | 1.2-1.4 | 9 | 16.16 | 12.7mm | 9 | 5 |

200*900 | 15 | 1.2 | 10.2 | 13.22 | 12.7mm | 7 | 6 & peach |

120*120 | 15 | 1.2-1.4 | 6 | 8.86 | 7mm | 12 | 11 |

150*1200 | 15 | 1.2-1.4 | 7.5 | 10.24 | 9.5mm | 14 | 13 |

180*1200 | 19 | 1-1.2 | 9 | 16.16 | 12.7mm | 10 | 11 |

200*1200 | 22 | 1-1.2 | 10.2 | 13.22 | 12.7mm | 10 | 8 |

250*900 | 18.5 | 1.2 | 12.6 | 11.1 | 12.7mm | 7 | 6 & peach |

300*900 | 22 | 1.2 | 15 | 10.83 | 12.7mm | 8 | 5 & peach |

220*1200 | 24 | 1-1.2 | 10.5 | 10.9 | 12.7mm | 9 | 8 |

250*1200 | 26 | 1-1.2 | 12.6 | 11.1 | 12.7mm | 10 | 8 |

300*1200 | 33 | 1-1.2 | 15 | 10.83 | 12.7mm | 12 | 6 |

We can design and manufacture specific model according to customers’ specific requirement. | |||||||

The machine works on the concrete platform, using pre-stressed steel wires as guidance,

electric motor aspower to push the concrete into concrete slabs while walking along the steel wires.

The continuously working of vibration plate will highly classify the concrete. Meanwhile,

the reaction of pushing materials by slider will move the equipment go along with the steel wire overcoming

the frictional resistance.After nearly 48-hour maintenance, it can be cut into concrete slabs for use.

Neutral packing and shipping by sea and train .

1.High load capacity, large span and good Anti-seismic performance. |

2.Fire resistant, heat insulation, sound insulation performance is good. |

3.Easy to forming up: The hollow core slab specifications can be customized according to the need of project, customer can choose different specifications according the building demend. |

4.Energy conservation and efficient: This hollow slab machine adopt advance production technology of extrusion molding, without molds and steam curing, reduce the labor cost, largely improve the production efficiency. |

5.Reasonable design: The hollow slab using steel cable for longitudinal reinforcement, have good toughness, strength, reasonal structure design, superior to other similar panels. |

6.Save time and labor cost: Hollow slab can be directly used as the floor slab and roof slabs, also can put on decorative brick, dry sticks stone on slabs for surface finishes. This can save rendering process, save labor and money. At the same time, avoid crack if plastering. |

| 7.Compared with casting- in- place, the hollow core slab with low steel consumption, low cost, its simple construction process, largely shorten the construction period, reduce labor cost, raw materials cost and comprehensive cost of construction projects. |

1) Send the technicians to carry out the installation and debugging of equipment for the foreign users with compensation.Countries or regions with unstable political situation or in the throes of wartime are not included in our plan.

2) Train the users to command the equipment and guide them for safe production.

3) Explain the routine maintenance of equipment carefully and remove common faults.

4) We are responsible for all the repairs that caused by our quality problems within one year’s warranty. (We will provide one set of spare parts/wear & tear parts free of charge with shipment.)

5) For some countries whose visas are difficult obtained, customers can also send their technicians to our company to receive free guidance and training.

6) Accept suggestions for improvement put forward by customers an earnest way. In accordance with changes of the market, provide the products and services to meet the user’s needs and create value for them.

7) We will make every effort to solve your problems, and your success will add new glory to us. |

-

Concrete wall fence panels/precast concrete fence moulds/hollow cement slab wall precast parts for sale

-

Prefabricated hollow panel/sandwich panel production line/prefabricated concrete mold for prefabricated board room

-

Double Layer Roll Forming Machine Roll Forming Machine Metal Roof Corrugated Steel Sheet Wall Panel Tile Making Machine

-

Portland cement foam insulation board production line / prefabricated foam cement wall panel machine

-

precast concrete formwork/precast concrete stairs

-

Concrete Precast House Precast House Precast Concrete Fence Mold Plastic EPS Hollow Panel Sandwich Panel Machine

-

Prestressed concrete T-beam machine

-

Concrete Wall Panel Making Machine Light Weight Precast Wall Panel Machine for Concrete Panels

-

Sheet Manufacturing Machinery Embossing Machine Products 2020 Automatic Flooring Building Materials Embossing Metal New

-

precast compound concrete hollow core wall panel making machine