metal light gauge steel frame forming machine

-

Supplier: Cangzhou Zhongtuo International Trade Co., Ltd. -

Region: Hebei, China -

Contact: Mr Cary xu -

Price: $12000.00 /set -

Min. Order: 1 set

| material of blades: | Cr12 quenched; | Voltage: | 380V/50HZ 3Phase(as Request); |

| Brand Name: | zhongtuo; | Type: | Steel Frame & Purlin Machine; |

| After-sales Service Provided: | whole life; | Weight: | 3.5T; |

| drive system: | by gear; | Product name: | light gauge steel frame forming machine; |

| roller material: | Gcr12mov quenching; | Dimension(L*W*H): | 6.8*0.8*1.2m; |

| Supply Ability: | 30 Set/Sets per Month c channel steel roll forming machine; | Production Capacity: | 30-40m/min; |

| shaft material: | 40Cr steel; | Port: | XINGGANG TIANJIN; |

| Certification: | ISO; | forming steps: | customized; |

| material thickness: | 0.4-0.8mm; | Condition: | New; |

| Power(W): | 3kw+3kw; | hydraulic oil: | 46#; |

| Place of Origin: | Hebei China; | Warranty: | 2 years; |

| Packaging Detail: | 1.One 20ft container for loading one set machine with manual decoiler. 2.The whole wiped anti rust oil ,PLC controller covered by foam film. 3.Spare parts and some small parts packed in plastic tooling box. 4.All components of c channel Roll Forming machine fixed by steel wire.; | After-sales Service Provided: | Online support,Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Video technical support; |

| Payment Terms: | L/C,D/A,T/T,30%T/T ,Balance to be paid before shipping after inspection.; |

metal light gauge steel frame forming machinemetal light gauge steel frame forming machine

This light gauge steel frame forming machine is fully automatic and high speed producing continuously,

one set of forming rolls can produce various sizes of Stud and Runner just by simply and easily changing the spacers,

this enables the production of different sizes products on the same rollers.

This light gauge steel frame forming machine is fully automatic and high speed producing continuously,

one set of forming rolls can produce various sizes of Stud and Runner just by simply and easily changing the spacers,

this enables the production of different sizes products on the same rollers.

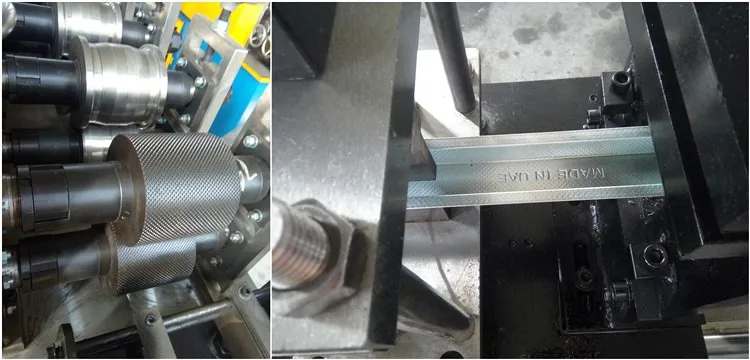

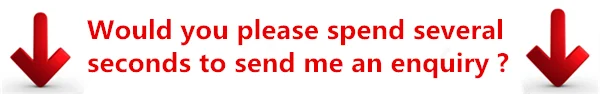

The following is a detailed description of some parts of the molding machine.

The light steel keel forming machine has the following characteristics:

2. The overall machine costs less

3. Lower energy consumption

4. This machine is safer and more efficient

Below is a layout of some machine outputs.

What is the producing process of light gauge steel frame forming machine?

What is the specifications of light gauge steel frame forming machine?

| Name | light gauge steel frame forming machine |

| Raw material | Galvanized |

| Thickness | 0.3-0.8mm |

| Inner Diameter | 450-550mm |

| Max Coil width | 300mm |

| Capacity | 1.5T |

| Forming steps | 10 rollers |

| Shaft diameter | 40mm |

| Design type | Memorial arch |

| roller material | GCr12MoV steel |

| shaft material | 45# steel |

| Work speed | 0-25m/min |

| Transport | By gear |

| Power of main machine | 3kw |

| Type of cutting | Hydraulic |

| Cutting tolerance | ±1mm |

| Cutter | Gcr12 |

| Hydraulic oil | 46# |

| Hydraulic power | 3kw |

| PLC Brand | Delta(as your requirement) |

feasures for the final goods:

1.Galvanized Zinc coating will protect the channel from being rust;

2.Flexibility of application makes each ceiling tile/plasterboard easily installed and disconnected;

3.Size adjustability can easier to match your request;

4.High quality leads longer life span & higher strength;

5.Better function of dealing with both high tensile stress and blending stress.

6. Easy and fast for installation,time-saving

What is the Advantages of light gauge steel frame forming machine?

1.Holes and embossinag

All C light gauge steel frame forming machines can be set-up with a Service Hole, Dimple Punch, Index/Bolt Hole and Web-notch tools.

2.high speed

Servo driven punch provides close tolerance accuracy and none stop punching for increased production,

with interchangeable tooling for different hole sizes and shapes.

Or just contact us directly

June Wang (sales manager)

whatsapp/wechat:+8615127778288

-

High speed metal roll forming machine and track

-

c light keel forming frame cad light steel machine

-

House light steel villa light steel keel forming machine

-

Electrical Cabinet Shelf Roll Forming Machine Using Elephant Roll Forming Technology

-

Light steel keel equipment keel rolling forming frame dividing machine

-

Popular c panel channel steel stud light weight keel equipment roll forming machine

-

metal frame for making drywall drywall, stud rolls, cu shaped light keel forming machine

-

Precast Concrete Fence H Beam Making Machine After Precast Concrete Fence

-

Gypsum Board Ceiling Steel Fur Channel Forming Machine Omega Channel Forming Machine

-

PLC controlled steel CZ purlin roll forming machine for quick replacement

Other Products

-

$70000.00 - $85000.00 / set

$70000.00 - $85000.00 / set -

$20000.00 / set

$20000.00 / set -

$5000.00 / set

$5000.00 / set -

$15000.00 - $23000.00 / set

$15000.00 - $23000.00 / set -

$27800.00 - $29800.00 / set

$27800.00 - $29800.00 / set -

$20000.00 / set

$20000.00 / set -

$2500.00 / set

$2500.00 / set -

$24000.00 / set

$24000.00 / set -

$14000.00 / set

$14000.00 / set -

$10000.00 / set

$10000.00 / set