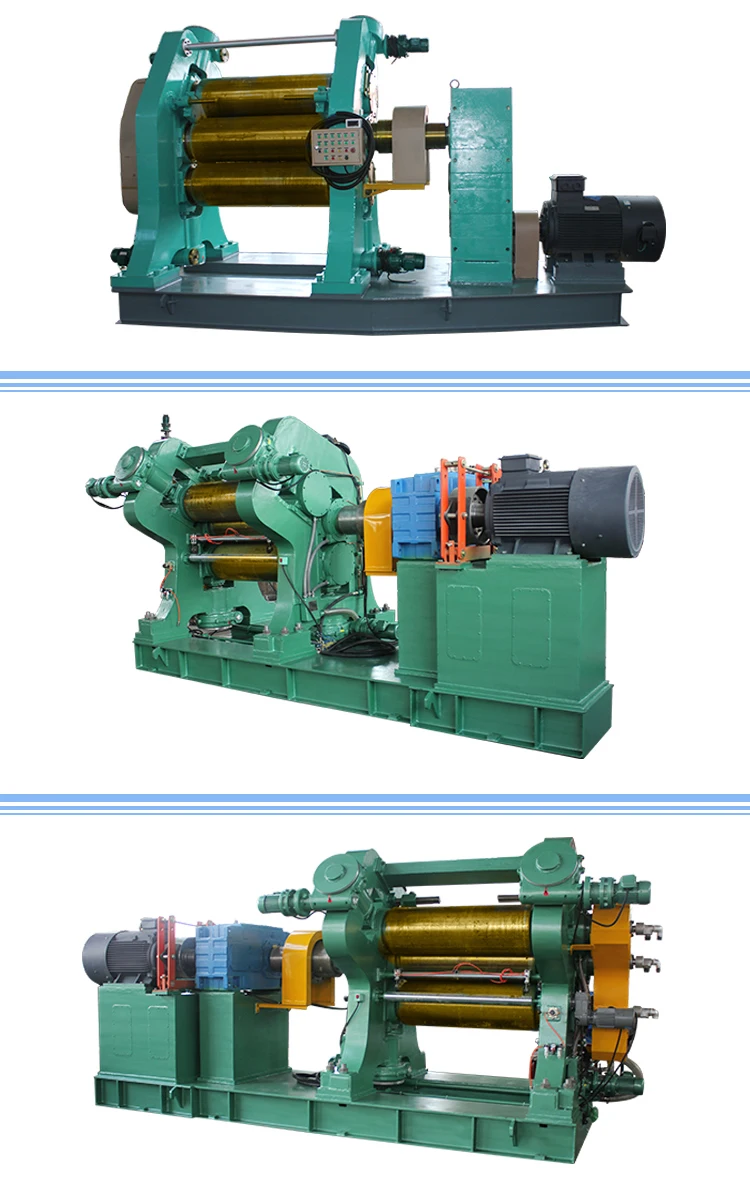

3 roll rubber calender machine for rubber sheet

-

Supplier: Qingdao Everfine Machinery Co., Ltd. -

Region: Shandong, China -

Contact: Mr David Shao -

Price: $20000.00 /set -

Min. Order: 1 set

| Payment Terms: | L/C,D/P,T/T; | Roller Diameter: | 230mm; |

| Brand Name: | Everfine; | Structure: | I, L type; |

| Keyword: | Rubber calender; | Place of Origin: | Shandong China; |

| Condition: | New; | Power(W): | 7.5KW; |

| Speed Ratio: | According to customer's request; | Warranty: | 1 YEAR; |

| Roller Working Length: | 630mm; | Certification: | CE, ISO; |

| Supply Ability: | 10 Set/Sets per Month; | Nip Adjust Scope: | 0.1~7mm; |

| Applicable Industries: | Manufacturing Plant; | Weight: | 2600kgs; |

| After-sales Service Provided: | Online support; | Key Selling Points: | good quality and price; |

| Middle Roller Linear Speed: | 0.8~8m/min; | Dimension(L*W*H): | 3168*890*1830mm; |

| Max Calendering Product Width: | 500mm; | Port: | Qingdao; |

| Power: | 7.5KW; | Package Preview: | ; |

| Voltage: | 220v, 380v, 415v, 440v, 460v, 480v, ect.; | Product Name: | Three roller rubber calender machine; |

| Packaging Detail: | Wooden case or no packing; |

3 roll rubber calender machine for rubber sheet

Three roller rubber calender is mainly used to roll-extrusion for rubber sheet, conveyor belt. sticking & friction rubber of fabrics.

1) Calender line for coating textile tire cord fabric (tire industry).

2) Calender line for inner liner, rim cushion and rubber sheet laminating (tire industry).

3) Calender line for coating textile conveyor cord fabric.

4) Calender line for industrial rubber film and sheet.

This type of three roller rubber calender machine is consisted of bedplate, frame, rollers, motor, coupling, gearbox, adjusting spacing device, the adjusting temperature device of roller, etc .

Features:

1) The bedplate is whole model, installation convenience.

2) Rollers are made of chilled cast alloy iron, the working surface of roller is hardness and smoothly. Steam and cooling water can pass through inner of the rollers so that surface temperature can be adjustable.

3) Adopt roll bearing, high precision, long service life, axes pathway is no abrasion.

4) Full range of bending deflections is optional including middle height, inflection and axis crossing.

5) Adjusting spacing device is consisted of one left and one right hand wheel. The bearing bases need is moved and reached nip by worm and worm wheel. Roller space can be adjusted manually or by electric motor.

6) Roller arrangement can be “I” type, “F” type, “L” type and “invert L” type.

7) The speed reducer is the hard-tooth surface gear reducer of class 6 precision, which has long service life and low noise.

8) Perfect emergency stop device can ensure the safety of person and equipment.

We may design and produce it as per customers’ requirements, equip various accessories, composing combined product line. Below is the main parameters:

Model | XY-230X630 | XY-360X1120 | XY-400X1400 | XY-450X1500 | XY-610X1730 | XY-710X2130 | XY-810X2430 |

Roller Diameter | 230mm | 360mm | 400mm | 450mm | 610mm | 710mm | 810mm |

Roller Working Length | 630mm | 1120mm | 1400mm | 1500mm | 1730mm | 2130mm | 2430mm |

Middle Roller Linear Speed (m/min) | 0.8~8 | 3~21.06 | 3~26.39 | 2.62~26.2 | 5.4~54 | 8~50 | 3~30 |

Nip Adjust Scope (mm) | 0.1~7 | 0.1~10 | 0.1~10 | 0.1~10 | 0.1~15 | 0.1~15 | 0.1~15 |

Max Calendering Product Width | 500mm | 920mm | 1200mm | 1300mm | 1500mm | 1900mm | 2150mm |

Power | 7.5kw | 45kw | 55kw | 75kw | 132kw | 185kw | 220kw |

Weight (kgs) | 2600 | 11000 | 22000 | 26000 | 52000 | 67000 | 94000 |

-

PTFE Seal Tape Machine

-

PTFE film with custom ePTFE membrane, waterproof, breathable

-

Rubber Calender/Three Roll Calender/Four Roll Calender for Rubber Coating

-

Three Roller Rubber Calender

-

Three-roll/four-roll calenders (for conveyor belt production)

-

Machine for the production of ptfe tapes

-

Four Roller Calender/PVC Calender/Four Roller Rubber Calender

-

Artificial PVC Film PVC Hard Film Extrusion Line

-

Calendar Chinese Manufacturer Used rubber calendar with three rollers

-

410*1350 PVC hard film rolling machine extrusion calendering mixing whole production line

Other Products

-

-

$6000.00 / set

$6000.00 / set -

$18000.00 / set

$18000.00 / set