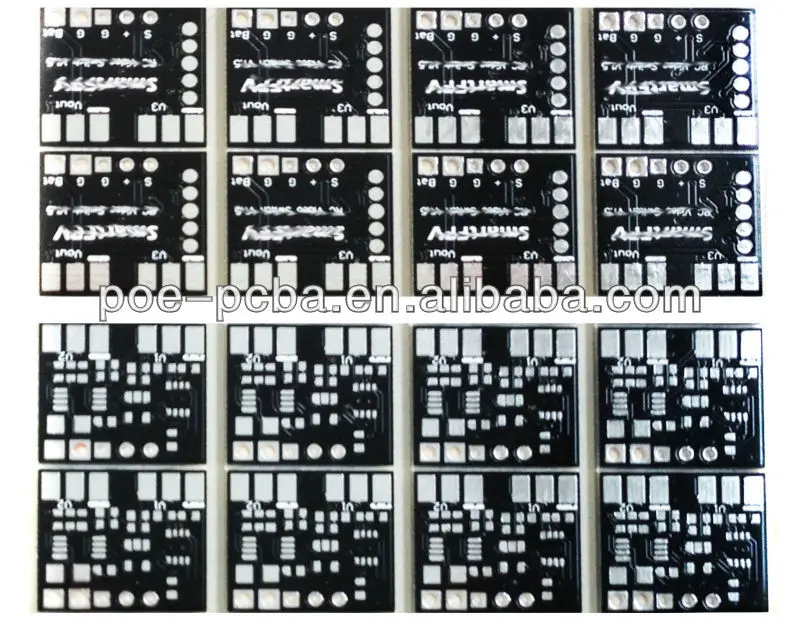

2 Layer Micro SD Card PCB

-

Supplier: Shenzhen POE Precision Technology Co., Ltd. -

Region: Guangdong, China -

Contact: Ms Vicky Liang -

Price: $1.00 /piece -

Min. Order: 1 piece

| Finised copper thickness: | 1-6OZ; | Model Number: | PCB-5359; |

| Payment Terms: | L/C,T/T,Western Union,Micro SD Card PCB; | Solder Mask Color: | Green\White\Red\Blue\Black; |

| Layers: | 1-28; | Min. Line Width: | 0.1mm; |

| Supply Ability: | 30000.0 Square Meter/Square Meters per Month Micro SD Card PCB; | Impedence Control Tolerance: | ±5%; |

| Brand Name: | POE; | Place of Origin: | Guangdong China; |

| China: | Micro SD Card PCB; | PCB Standard: | IPC-A-610 D; |

| Finished board thickness: | 0.2-7.0mm; | Port: | Shenzhen; |

| Board Size: | Optional; | Min. Hole Size: | 0.2mm; |

| Surface Finishing: | HASL lead free; | OEM/ ODM Service: | One-stop turnkey Service; |

| Copper Thickness: | 1oz; | Color: | Green,Blue,Black,Red,Yellow,white; |

| Min. Line Spacing: | 0.1mm; | Packaging Detail: | CNC package for bare PCB and ESD package for PCBA assemble with POE box Package; |

| Base Material: | FR4; | Hole tolerance: | PTH: ±3mil, NTPH: ±2mil; |

| Board Thickness: | 1.6mm; |

China Micro SD Card PCB

|

1.High quality micro SD card pcb 2.2 Layer HASL lead free SD pcb 3.Double sided black solder mask pcb 4.100%E-test before shipment 5.One-stop turnkey service 6.Small order is acceptable |

|

WELCOME TO POE

We are able to provide you best electronics services.

- PCB Production Service. (FR-4,HI-TG,Aluminum,FPC,TEFLON,CEM-1 )

- FPC,PCB Copy Service.

- PCB Assembly Service. (SMT, BGA, DIP)

- PCBA Housing assembly serivce.

- PCBA Final Functional Testing

- PCBA Copy Service.

- Electronic Components Purchasing & BOM List Purchasing Services.

- PCB SMT Stencil. (Laser cut & Etching)

1. POE PCB Manufacture Capability

|

Item |

Capability |

|

|

1.Base Material |

FR-4 / High TG FR-4 / Lead free Materials (ROHS Compliant) / Halogen Free material /CEM-3/CEM-1/ /PTFE/ROGERS/ARLON/TACONIC |

|

|

2.Layers |

1-28 |

|

|

3.Finised inner/outer copper thickness |

1-6OZ |

|

|

4.Finished board thickness |

0.2-7.0mm |

|

|

Tolerance |

Board thickness≤1.0mm: +/-0.1mm 1 Board thickness>2.0mm: +/-8% |

|

|

5.Max panel size |

≤2sidesPCB: 600*1500mm Multilayer PCB: 500*1200mm |

|

|

6.Min conductor line width/spacing |

Inner layers: ≥3/3mil Outer layers: ≥3.5/3.5mil |

|

|

7.Min hole size |

Mechanical hole: 0.15mm Laser hole: 0.1mm |

|

|

Drilling precision: first drilling |

First drilling: 1mil Second drilling: 4mil |

|

|

8.Warpage |

Board thickness≤0.79mm: β≤1.0% 0.80≤Board thickness≤2.4mm: β≤0.7% Board thickness≥2.5mm: β≤0.5% |

|

|

9.Controlled Impedance |

+/-5% |

|

|

10. Aspect Ratio |

15:1 |

|

|

11.Min welding ring |

4mil |

|

|

12.Min solder mask bridge |

≥0.08mm |

|

|

13.Plugging vias capability |

0.2-0.8mm |

|

|

14. Hole tolerance |

PTH: +/-3mil NPTH: +/-2mil |

|

|

15.Outline profile |

Rout/ V-cut/ Bridge/ Stamp hole |

|

|

16.Surface treatment |

OSP: 0.5-0.5um HASL: 2-40um Lead free HASL: 2-40um ENIG: Au 1-10U’’ ENEPIG: PB 2-5U’’/ Au 1-8U’’ Immersion Tin:0.8-1.2um Immersion silver: 0.1-1.2um Peelable blue mask Carbon ink Gold plating: Au 1-150U’’ |

|

|

17. E-testing pass percent |

97% pass for the first time,+/-2%(tolerance) |

|

|

FQC-Physical Lab: Reliability tests |

||

|

18.Certificate |

ROHS E327776 ISO9001:2008 IPC SGS |

|

|

|

||

|

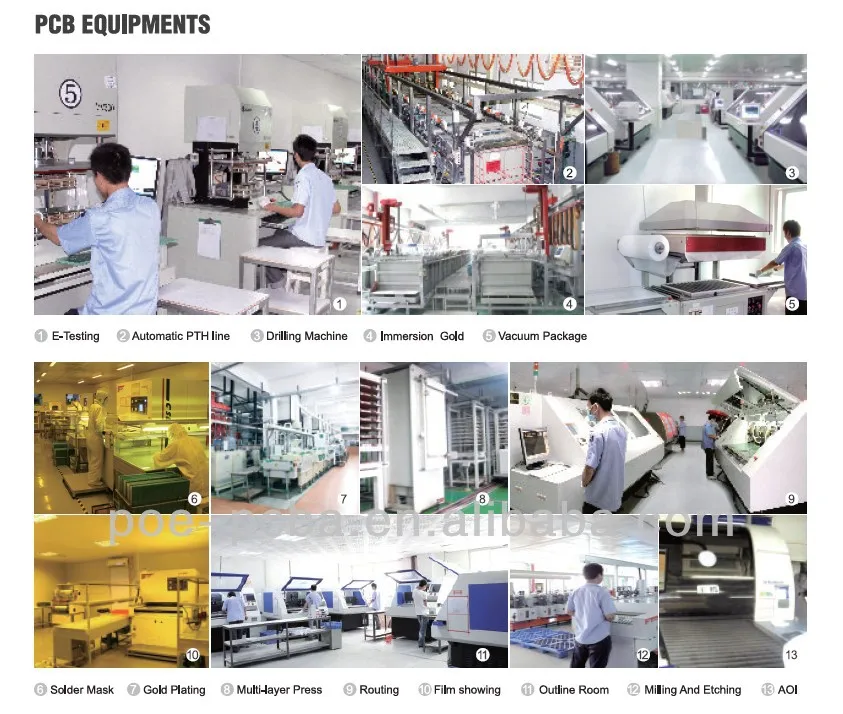

Our equipments |

||

|

1.Drilling workshop |

4 drilling bits of drilling machine: 4 sets 2 drilling bits of drilling machine: 2 sets |

|

|

2. photo plotting workshop |

Israel “ORBOTECH” Photo Plotters |

|

|

3.AOI |

AOI machine |

|

|

4.IPQC |

“OXFORD” CMI 700 Copper Thickness Tester |

|

|

5.Impedance test |

USA “Tektronix” DSA 8200 Impedance Tester |

|

|

6.Outline workshop |

CNC routing machine: 7 sets angle-cutting machine V-cut machine |

|

|

7.Testing Workshop |

Surpass X-600: 2sets WTD FT-2808: 5sets WTD HV300: 1set |

|

|

8.X-ray |

X-ray machine |

|

|

|

||

|

Acceptable file format |

||

|

GERBER file, PROTEL series, PADS series, POWER PCB series, AutoCAD series. |

||

|

|

||

…………… …………… ………………

2.Multilayer Manufacture Process

…………… …………… ………………

3.Leadtime for bare PCB

…………… …………… ………………

4.POE Partners

…………… …………… ………………

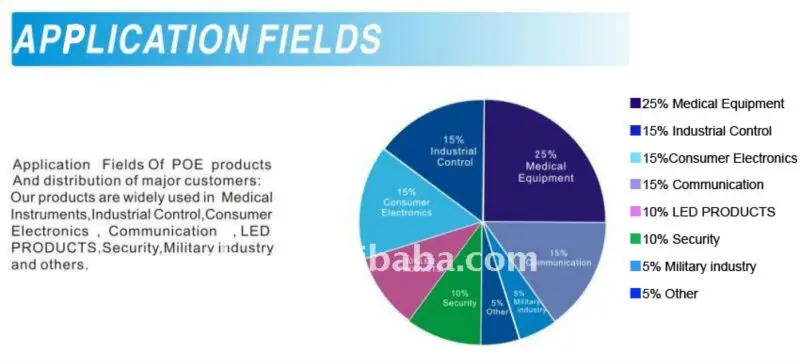

5. Application Fields&Customers

…………… …………… ………………

6.Production line

…………… …………… ………………

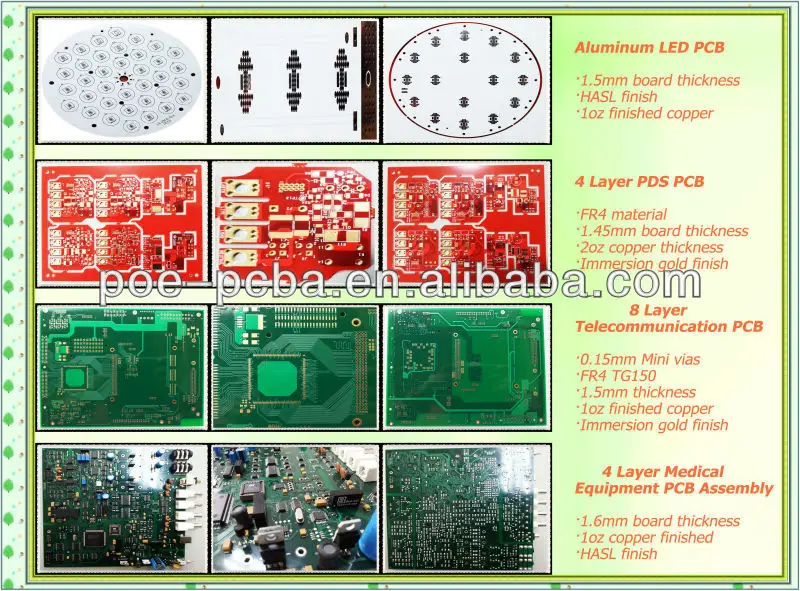

7.Products Show

…………… …………… ………………

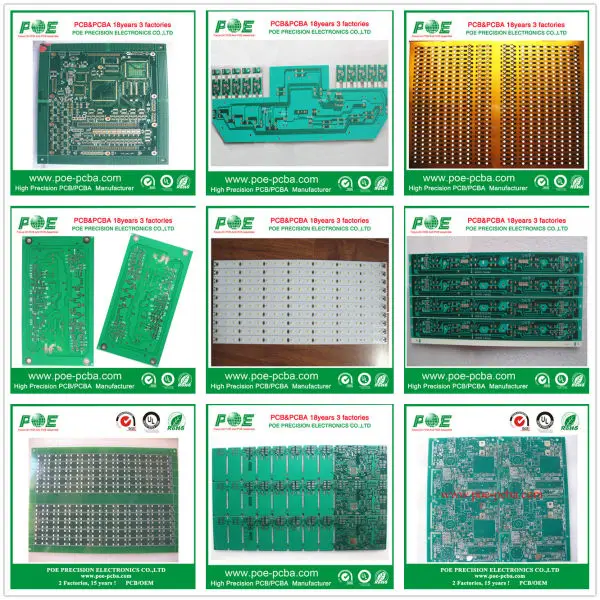

8.PCB&PCBA

…………… …………… ………………

9. POE Invitation

10. PCB

-

Customized single sided round aluminum substrate, 12v led light circuit board factory

-

Support professional double-sided PCB design one-stop OEM service

-

Custom electronics contract manufacturing double sided pcb assembly

-

Wholesale Lighting Led Pcb Led Board Design Led Circuit Board 3535 5730 3w 5w 7w 9w 12w 15w 18w Smd LED Printed Circuit Board

-

Free Shipping 100% Original HDD PCB Logic Board 2060-800041-003 REV P1 Hard Drive Circuit Board 2060-800041-000 REV P1

-

best china kb 3151c fr-1 pcb with rohs long life

-

China Printed Circuit Board Automotive Mobile Medical PCBA Assembly PCB Design Service

-

RDS Electronics- Circular board PCB aluminum factory MCPCB 2835 LED SMD 5630 aluminum PCB

-

5G mobile phone FR4 PCB manufacturer Shenzhen

-

Shenzhen ODM double-sided PCB designer and Customized PCB Manufacturer

Other Products

-

$0.50 - $3.00 / piece

$0.50 - $3.00 / piece -

$0.10 - $10.00 / piece

$0.10 - $10.00 / piece -

$1.00 - $15.00 / piece

$1.00 - $15.00 / piece -

$0.15 - $5.00 / piece

$0.15 - $5.00 / piece -

$0.50 / piece

$0.50 / piece -

$0.50 - $10.00 / piece

$0.50 - $10.00 / piece -

$0.10 / piece

$0.10 / piece -

$0.10 / piece

$0.10 / piece -

$0.25 / piece

$0.25 / piece -

$0.25 / piece

$0.25 / piece