TFE high efficient used oil refinery thin film evaporator

-

Supplier: Wenzhou Aowei Machinery Co., Ltd. -

Region: Zhejiang, China -

Contact: Ms Tina Zhang -

Price: $15000.00 /set -

Min. Order: 1 set

| Voltage: | 220-440; | Marketing Type: | New Product 2020; |

| Supply Ability: | 10 Set/Sets per Month used oil refinery equipment; | Applicable Industries: | Machinery Repair Shops,Food & Beverage Factory; |

| Warranty of core components: | 1 YEAR; | Condition: | New; |

| Machinery Test Report: | Provided; | Packaging Detail: | plastic film and cotton cloth and wooden cases-used oil refinery equipment.; |

| Warranty: | 1 YEAR; | TYPE 1: | rotary; |

| Core Components: | engine,Bearing; | Flow: | TBD; |

| Local Service Location: | none; | Package Preview: | ; |

| Power(W): | 0; | type 2: | thin film; |

| Port: | Shanghai/Ningbo; | After-sales Service Provided: | Engineers available to service machinery overseas,Field installation, commissioning and training; |

| Showroom Location: | none; | Certification: | CE; |

| Weight: | TBD; | Place of Origin: | Shanghai China; |

| Video outgoing-inspection: | Provided; | materil: | stainless steel 304,316L; |

| After Warranty Service: | Video technical support,Online support,Spare parts; | Payment Terms: | L/C,T/T; |

| Dimension(L*W*H): | TBD; | Brand Name: | ONW; |

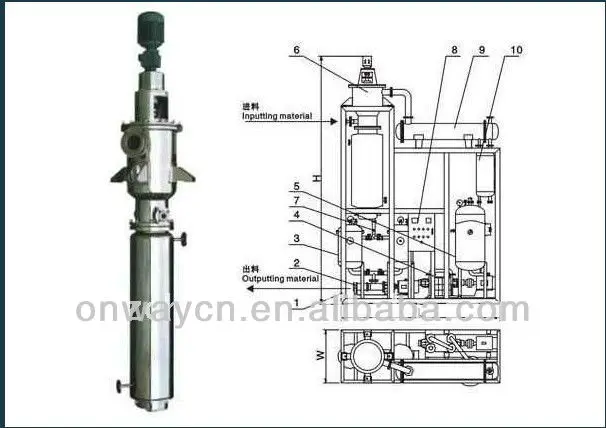

Used oil recycling plant is a newly developed product which combines dozens of our latest technologies. It is able to rapidly extract light and heavy distillates from different fractions by given different temperatures control along with our own formulated catalyst compound. It can also remove the Metallic Compound, Base Nitrogen, Sulfur etc. from distilled oil during Re-refining process.

Main Features:

1. Its heat transfer coefficient value is high, and its evaporation capacity can achieve 200kg/m2 per hour, with high thermal efficiency.

2. Material heating time is short, from 5 seconds to 10 seconds. Under vacuum conditions, the equipment can favorably retain heat-sensitive material's various ingredients, and produce non-decomposition, to ensure the quality of products.

3. Agitated thin film evaporatoris adapt to wide range of viscosity. Material of high viscosity can also be processed. Material viscosity can be as high as 10 million per cent tabor (CP).

4. Changing the rotation direction of the scraper groove, can adjust the process time of material in the evaporator.

5. The wall of agitated thin film evaporatorcylinder body is after precision milling and polishing processing, so its surface is not easy to generate coking, fouling.

Below is the small wiped thin film evaporator(for test machine ) to South Korea :

(And they have already order the bigger one , because the customer is satisfied the test result )

Below is the small wiped thin film evaporator to Canada:

used oil refinery equipment used oil refinery equipment used oil refinery equipment used oil refinery equipment used oil refinery equipment used oil refinery equipment used oil refinery equipment used oil refinery equipment

-

Yangjiang waste oil refining equipment recycling waste motorcycle or automobile oil waste oil regeneration machine

-

Recycling waste oil into diesel oil refinery is highly profitable and low cost

-

China Made Heavy Fuel Oil Distillation Mini Refinery

-

Standard Diesel and Gasoline or Crude Distillation Units in U.S. Crude Oil Refinery

-

2023 NEW Oil filter machine Oil filter equipment manufacturing

-

New continuous oil filter oil recovery machine

-

Factory supply portable oil purifier hydraulic oil filter cart oil purifier unit

-

500kg/day small edible oil refiner crude oil refiner HJ-JLYJ200

-

Distillation Unit Price of Small Crude Oil Refinery

-

New energy TYR waste oil to diesel plant edible oil recovery machine oil filter machine

Other Products

-

$6999.00 / set

$6999.00 / set -

$11900.00 / set

$11900.00 / set -

$100.00 / set

$100.00 / set -

$100.00 / set

$100.00 / set -

$9990.00 / set

$9990.00 / set -

$1000.00 / set

$1000.00 / set -

$500.00 / set

$500.00 / set -

$1000.00 / set

$1000.00 / set -

$1000.00 / set

$1000.00 / set