250a portable aluminium AC/DC/MIX tig welding machine MASTERTIG-250AC

-

Supplier: Hangzhou Topwell Technology Co., Ltd. -

Region: Zhejiang, China -

Contact: Mr Robin Yan -

Price: $695.42 /unit -

Min. Order: 1 unit

| Rated Input Voltage: | 220V; | power factor: | 0.73; |

| Single gross weight: | 32 KG; | Output Polarity: | AC/DC TIG; |

| efficiency: | 80%; | Package Preview: | https://sc02.alicdn.com/kf/HTB1AAxIaozrK1RjSspmq6AOdFXae.jpg_640x640.jpg; |

| Max. Load Power Capacity: | 7.81KVA; | open circuit voltage: | 10V; |

| Brand Name: | TOPWELL; | Condition: | New; |

| Certification: | CE, ROHS; | MOQ: | 1 set; |

| After-sales Service Provided: | Overseas service center available; | Motor Type: | DC MOTOR; |

| brand: | TOPWELL; | Place of Origin: | Zhejiang China (Mainland); |

| Cooling type: | Fan cooling, but water cooling unit optional.; | Warranty: | 1 Year; |

| Usage: | aluminium welding; | Voltage: | 220V; |

| Power(W): | 4.5kva; | Rated Output Current (TIG): | 250A; |

| Pilot Arc Current: | 5-250A; | Arc Current: | 5-250A; |

| Dimensions: | 517x230x451mm; | Delivery Detail: | 0 days after payment; |

| Single package size: | 58X26X57 cm; | Package Type: | carton box; |

| Pulse Frequency: | 0.2-20Hz; | weight: | 23kg; |

| Rated Duty Cycle @40°C (TIG): | 60%; | dimension: | 490x230x385mm(LxWxH); |

| Rated Output Voltage (TIG): | 20V; | Rated Duty Cycle: | 60%; |

| Selling Units: | Single item; | Welding Current/Voltage Range: | 5A/10.2V-250A/20V; |

| certificate: | CE,EMC,LVD; | After-sales Service Provided: | Free spare parts,Online support,Video technical support; |

| Material / Metal Processed: | Carbon Steel,Stainless Steel,Aluminium Alloy; |

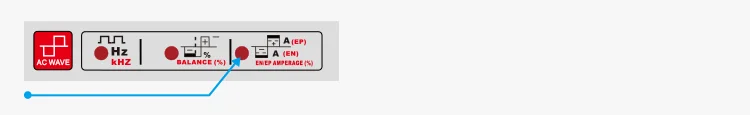

AC Frequency control

control the width of the arc cone. Increasing the AC Frequency provides a more focused arc with increased directional control.

Note: Decreasing the AC Frequency softens the arc and broadens the weld puddle for a wider weld bead.

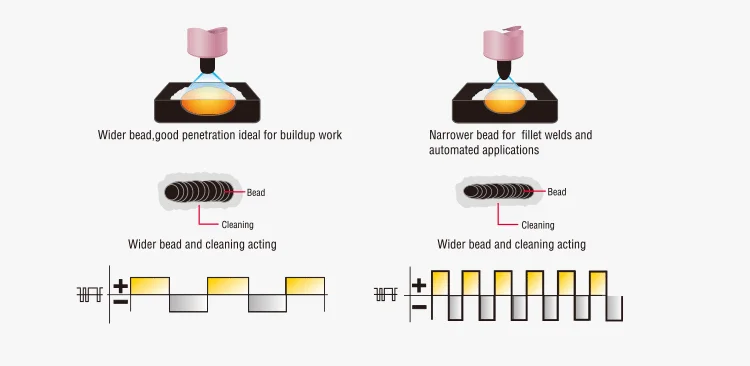

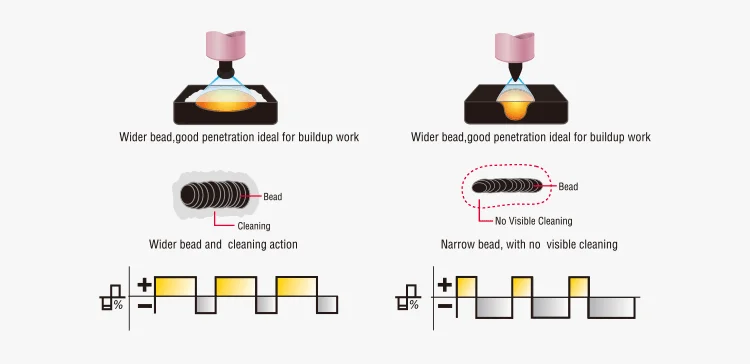

AC Balance Control

Controls arc cleaning action. Adjusting the % EN of the AC wave controls the width of the etchingzone surrounding the weld.

Note: Set the AC Balance control for adequate arc cleaning action at the sides and in front of the weld puddle. AC Balance should be fine tuned according to how heavy or thick the oxides are.

Independent AC Amperage Control

Controls arc cleaning action. Adjusting the % EN of the AC wave controls the width of Allows the EN and EP amperage values to be set independently. Adjusts the ratio of EN to EP amperage to precisely control heat input to the work and the electrode. EN amperage controls the level of penetration, while EP amperage dramatically effects the arc cleaning action along with the AC Balance control.

| Item No | MASTER TIG-250AC | ||

|---|---|---|---|

| Rated Input Voltage | 1PH ~ 230V ±15% | ||

| Max. Load Power Capacity | TIG: 7.81KVA | ||

| MMA: 8.75KVA | |||

| Rated Duty Cycle(40℃) 60% | TIG: 250A/20V | ||

| MMA: 200A/28V | |||

| 100% | TIG: 200A/18V | ||

| MMA: 160A/26.4V | |||

| Welding Current/Voltage Range | TIG: 5A/10.2V ~250A/20V | ||

| MMA: 20A/20.8V~200A/28V | |||

| Open Circuit Voltage | 70V~80V | ||

| Power Factor | 0.8 | ||

| Efficiency | 80% | ||

| TIG | Pulse | Peak Current | 5A~250A |

| Pulse Frequency | 0.2Hz~200Hz | ||

| Pulse Width (Ratio) | 1~100% | ||

| AC TIG | AC Frequency Range | 20Hz~250Hz | |

| AC Clean Width (AC Balance) | +40~-40 | ||

| AC Clean Ratio (AC Bias) % | +30~-50 | ||

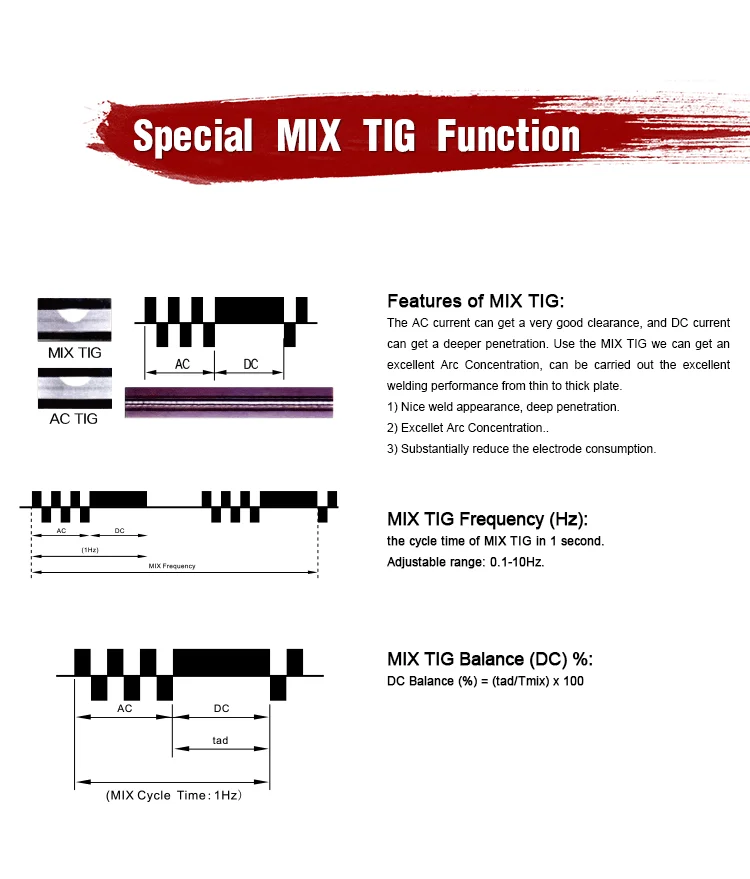

| MIX TIG | MIX Frequency | 1Hz~5Hz | |

| DC Balance (%) | 20~80 | ||

| Arc-starting Current | 5A~250A | ||

| Crater-filling Current | 5A~250A | ||

| Current Up-slope Time | 0.1S~15S | ||

| Current Down-slop Time | 0.1S~15S | ||

| Pre-Gas Time | 0.1S~15S | ||

| Flow-Gas Time | 0.1S~15S | ||

| Spot Arc Time | 0.1S-10S | ||

| MMA | Arc Force | 10A~200A | |

| Hot Start Time | 0.1~3S | ||

| Hot Start Current | 10A~200A | ||

| Dimension (LxWxH) | 490x230x440mm | ||

| Weight (KG) | 23KG | ||

-

ANDELI new product Tig-250MPC 4IN 1 Mig TIG lift tig clean welding machine

-

Andre 6-in-1 MIG, CUT, TIG, cold, MMA aluminum welding machine multifunctional welding machine specially designed

-

JONE inverter AC/DC pulse field effect tube argon arc welding machine AC and DC welding machine argon aluminum argon arc welding machine

-

SANYU TIG-315P TIG-315PW AC/DC argon arc welding machine aluminum argon arc welding machine

-

110V/220V TIG WelderARC TIG 2 in 1 Welder140Amp Stick MMA IGBT Smart Inverter

-

HITBOX AC aluminum welding machine HBT250P ACDC professional TIG pulse MMA ARC inverter welding machine 2T 4T semi-automatic control function

-

K tig welding with deep penetration

-

Multifunctional 5 in 1 plasma cutting machine ac dc tig mma pulse welding machine

-

ANDELI new product TIG-250PE TIG aluminum welding machine hot sale HF/LIFT TIG/Pulse/MMA/AC DC multifunctional welding machine

-

Ideal for welding aluminum and stainless steel TIG welder TIG-200P AC/DC

Other Products

-

$3600.00 / piece

$3600.00 / piece -

$19.80 / set

$19.80 / set -

$695.42 / set

$695.42 / set