automatic industrial hydraulic sludge plate and frame chamber filter press equipment clay membrane filter press price

-

Supplier: Woking Environmental Technology Co., Ltd. -

Region: Guangdong, China -

Contact: Mr Ian Duan -

Price: $15000.00 / 1 - 2 sets

$7000.00 / >=3 sets -

Min. Order: 1 set

Product details

| Warranty of core components: | 1 Year; | Place of Origin: | Guangdong, China; |

| Item Name: | filter press manufacturer; | Dimension(L*W*H): | 4650*1100*1670; |

| Package Preview: | ; | Filter press type: | Automatic Filtration Machine; |

| Control: | Automatic Control Box; | Advantage: | Energy Saving; |

| Warranty: | 1 Year; | Marketing Type: | Ordinary Product; |

| Application: | Dewatering; | Power: | 2.2kw; |

| Machinery Test Report: | Provided; | Showroom Location: | Viet Nam,Thailand,Malaysia; |

| Type: | high pressure; | Filter area: | 1-50m2; |

| Brand Name: | WORKING; | Weight: | 3150 kg; |

| Video outgoing-inspection: | Provided; | Applicable Industries: | Building Material Shops,Manufacturing Plant,Food & Beverage Factory,Construction works ,Energy & Mining,Other,Mining, Stone industry, Ceramic industry; |

| Product name: | Plate And Frame Filter Press Machine; | Voltage: | customized; |

| Keywords: | Wastewater Sludge Dewatering Equipment Press Filter; | Payment Terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram; |

| Core Components: | High Efficiency,high pressure,Filter press,manufacturer; | Material of filter plate: | Reiforced PP; |

Product Description

Mining Stone Industry Ceramic Industry Membrane Filter Press

Model | XMYZG1000-UB |

Industry applications | Mining, Stone industry, Ceramic industry |

Condition | Brand New |

Application | solid-liquid separation |

Power | 2.2KW |

Filter area | 80m2 |

Place of Origin | Guangdong, China |

Brand Name | WOKING |

Dimension | 6870*1560*1360mm |

Warranty | 1 year |

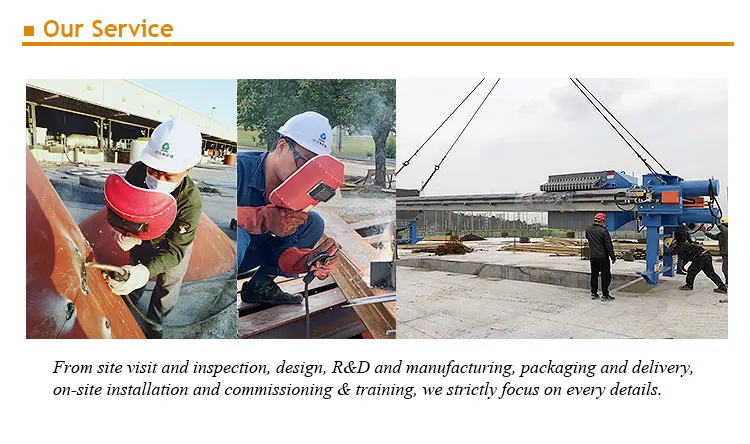

After-sale Service | online support, installation instruction, commissioning and training |

Name | membrane filter press |

Type | Automatic filter press |

Material | Carbon steel |

Packing | Seaworthy package |

OEM | Yes |

Delivery time | 30days/ negotiable |

Payment | L/C or T/T |

Life | More than 10 years |

supply ability | 50 sets/month |

Applications

Filter press is suitable for almost all types of slurry, such as: ceramics industry, stone industry, glass industry,

mining & minerals industry, coal washing, sand washing, pull&paper industry, food industry, chemical & pharmacy industry,

electroplating industry, textile& dyeing, leather industry, municipal slurry etc.

mining & minerals industry, coal washing, sand washing, pull&paper industry, food industry, chemical & pharmacy industry,

electroplating industry, textile& dyeing, leather industry, municipal slurry etc.

Feature

lower residual moisture, High capture rate, low energy requirement, Reliable, automatic operation, Solid and robust design for demanding operating conditions, Long service life, High operating availability, Free access to plate pack, Special design for aggressive media, Customer-oriented process solution thanks to modular design

Technical Parameters

Filtration area(㎡) | Thickness of filter plate(mm) | Plate size(mm) | Thickness of filter cake(mm) | Chanbers NO.(pc) | Total volume(L) | Working pressure(Mpa) | Motor power(kW) | Weight(kg) | External dimensions(L*W*H)(mm) |

60 | 72/70 | 1000 | 40 | 38 | 1190 | ≤ 2.0 | 4 | 7670 | 6010*1560*1360 |

70 | 72/70 | 1000 | 40 | 44 | 1380 | ≤ 2.0 | 4 | 8090 | 6440*1560*1360 |

80 | 72/70 | 1000 | 40 | 50 | 1560 | ≤ 2.0 | 4 | 5810 | 6870*1560*1360 |

90 | 72/70 | 1000 | 40 | 56 | 1750 | ≤ 2.0 | 4 | 8930 | 7300*1560*1360 |

100 | 72/70 | 1000 | 40 | 62 | 1940 | ≤ 2.0 | 4 | 9350 | 7740*1560*1360 |

Optional facility

Product Description

Frame Filter press

High Pressure Filter Press

Membrane Filter Press

Automatic Filter Press

Stainless Steel Filter Press

Fast Opening Filter press

Working principle of Filter Press:

1. Slurry is pumped into the filter press. The solids are distributed evenly on the filter cloths during the feed (fill) cycle.

2. Solids begin to build on the filter cloth, trapping the ensuing particles and building a filter cake. The filter cake acts as a depth filter for solid/liquid separation. Filtrate exits the plates through the corner ports into the manifold.

3. When the correct valves in the manifold are open, the filtrate exits the press through the filtrate outlet. As the filter press feed pump builds pressure, the solids build within the chambers until they are completely full of filter cake.

4. Once the chambers are full, the fill cycle is complete and the filter press is ready to be emptied.

2. Solids begin to build on the filter cloth, trapping the ensuing particles and building a filter cake. The filter cake acts as a depth filter for solid/liquid separation. Filtrate exits the plates through the corner ports into the manifold.

3. When the correct valves in the manifold are open, the filtrate exits the press through the filtrate outlet. As the filter press feed pump builds pressure, the solids build within the chambers until they are completely full of filter cake.

4. Once the chambers are full, the fill cycle is complete and the filter press is ready to be emptied.

Case

Sand Making Industry

Kaolin Industry

Mining Industry

Tunneling Industry

Stone Industry

Potassium Feldspar

Coal Washing

Ceramic Tile Industry

Municipal slurry

VIEW MORE

You may like

-

Alcove filter press factory well glass plate, fiberglass filter plate

-

Cement sludge dewatering circular filter press with plunger pump

-

Durable, high quality water filtration membrane filter press with cloth cleaning drip tray

-

Ceramic round chamber filter press with favorable price automatic customized filter press

-

Machine builder’s automatic membrane PP filter press for breweries

-

Refinery Edible Oil Biodiesel Pressure Leaf Filter

-

Solid-liquid separation filter press for wastewater treatment

-

High pressure reinforced polypropylene filter press PP filter plate

-

Multi-layer stainless steel plate filter media

-

Oil wine clay ceramic automatic filter press concave plate filter press chamber filter press

Related Search

plate and frame filter presses

stainless steel beer plate and frame filter

plate and frame

optic len and frame suppliers

optic lens and frame suppliers

trailer wheel and frame

hydraulic steel plate bend testing machine

ce industrial hydraulic metal shear machine

hydraul shear plate suppliers

automatic industrial coffee machines