Batch drying type fish dryer/fish/sardine dryer

-

Supplier: Guangzhou Kaineng Electric Equipment Co., Ltd. -

Region: Guangdong, China -

Contact: Mr Tyler Page -

Price: $8000.00 /set -

Min. Order: 1 set

| application: | food processing | Dimensions (L*W*H): | 7500*3230*2200 |

| Voltage: | 220v-480v | Supply capacity: | 500 sets per year |

| feature: | High efficiency and low cost | Video external inspection: | if |

| Advantage: | Simple and efficient operation | Applicable industries: | Farm, Food and Beverage Store |

| port: | Guangzhou/Shenzhen/Hong Kong | payment terms: | L/C,Western Union,T/T |

| Evaporation (kg/h): | 25 | Material: | SUS304, SUS304 |

| Certification: | Chief Executive | Mechanical test report: | if |

| Install: | Engineer's Guide | brand: | Gimhae |

| After Warranty Service: | Video technical support, online support, spare parts | Main selling point: | long lasting |

| usage: | Industrial applications | After-sales service provided: | Online support, video technical support, free spare parts |

| Function: | drying + dehumidification | place of origin; place of origin: | Guangdong, China |

| Marketing Type: | normal product | Core Components Warranty: | 1 year |

| Warranty: | 1 year | Packaging Details: | Plywood (dryer + drying chamber + trolley and tray) |

| Raw materials: | Various materials | Health status: | new |

| Showroom location: | India | Core components: | Motor, PLC |

| strength: | 15.1 | Application materials: | Wide range of applications |

| Packaging Preview: | heating method: | electro-thermal | |

| product name: | Hot air dryer | Heat source: | electricity |

| Local service location: | India | Weight (kg): | 500 |

| type: | Tray Dryer |

Batch drying type fish dryer/fish/sardine dryer

What is a Kincaid Heat Pump Dryer?

A device that uses mechanical energy to transfer heat from a cooler area (ambient temperature) to a warmer area (drying room), such as a refrigerator.

Model:JK03RD,JK06RD,JK1RD

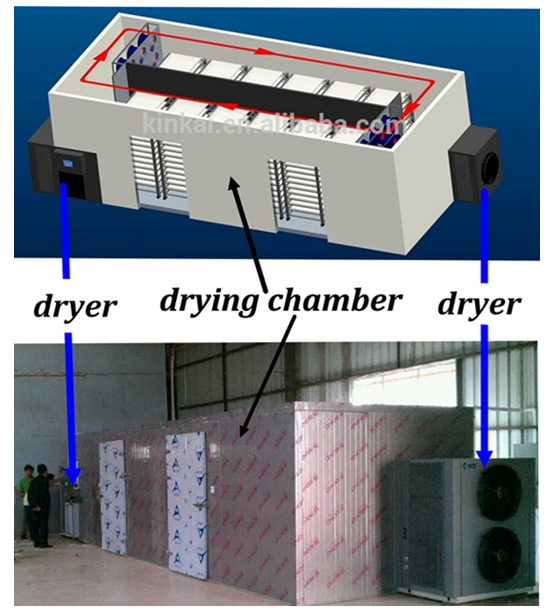

type:Heat pump dryer + drying chamber

power supply:220V/1PH/50HZ or 380V/3PH/50HZ

Thermal energy: 75% Air + 25% Electricity

maximum. temperature:75℃

Operating temperature:-10~45℃

Function:Heating/cooling/dehumidifying

Drying capacity:200~2500kg per batch

How does a dehydrator work?

1. The evaporator of the refrigerant dryer absorbs the outside air.

2. Then the compressor works to raise the air temperature.

3. The heat exchanger transfers the hot air into the drying chamber.

4. The final fish will be dried by the hot air circulating in the drying chamber.

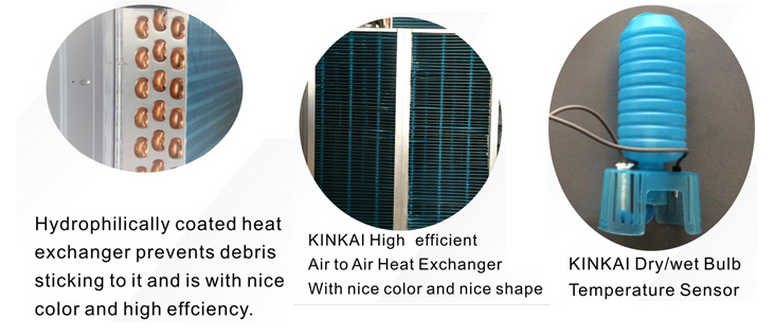

Accessories:

Features of Jinkai Heat Pump Dryer:

1. Adopt closed dehumidification + circulating drying method to save operating costs;

No waste gas and waste heat pollution, low noise

2. PLC+touch screen, easy to operate; Different drying curves can be set, suitable for drying of different materials.

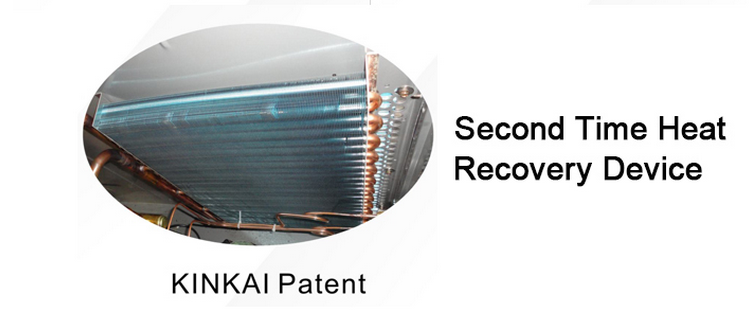

3. Secondary waste heat recovery technology (patent)

The air-to-air heat exchanger is used to dehumidify and recover waste heat at the same time, with high thermal efficiency and energy saving.

4. The forced ventilation function is adopted, and there is an adjustable air distribution board in the oven. The material is dry evenly.

5. Temperature: Hot air heating 10-75°C, up to 75°C.

6. The size and material of the baking pan can be customized according to customer requirements.

7. When drying, the material does not crack, deform, discolor, deteriorate, oxidize, dry thoroughly, rehydrate well, and maintain nutrients;

8. Safe and reliable operation, automatic intelligent control, 24-hour continuous drying.

Stable operation not affected by weather

Why choose Kingkey Heat Pump Dryer?

Technical parameters of Jinkai heat pump dryer

| Model | JK03RD | JK06RD | JK12RD | |

| Suitable for drying rooms | cubic meter | 10~20 | 20~30 | 30~40 |

| power supply | V/PH/HZ | 380/3/50 or 220/1PH/50 | 380/3/50 | 380/3/50 |

| power input | kilowatt | 2.8 | 5.8 | 13.8 |

| running current | One | 8/17 | 12.6 | 22.5 |

| Auxiliary electric heater (optional) | kilowatt | 9 | 9 | 9 |

| Heating capacity | kilowatt | 12 | 26 | 35 |

| cooling capacity | kilowatt | 7.5 | 20 | 25 |

| Dehumidification | length/height | 8 | 20 | 40 |

| maximum. Hot air temperature | °C | 75 | 75 | 75 |

| Working temperature | °C | -10~45 | -10~45 | -10~45 |

| The refrigerant | Kilogram | Mixture Type / 2.5 | Mixture Type/4.3 | Mix Type/8.0 |

| compressor | type | scroll | scroll | scroll |

| Card | Copeland/Danfoss | Copeland/Danfoss | Copeland/Danfoss | |

| quantity | 1 | 1 | 2 | |

| noise | dB(A) | 60 | 65 | 70 |

| fan motor for drying | Power Input/Unit | 250W/unit | 250W/unit | 250W/unit |

| Air volume | m3/hour | m3/hour | 2500m3/H/unit | |

| Recommended quantity | 8 | 8 | 16 units | |

| Regenerator size | mm | 500*350*350 | 500*500*580 | 550*600*680 |

| Fan motor for regenerator (dehumidification) |

power input | 200W | 370W | 550W |

| Air volume | 2000 cubic meters / hour | 2000 cubic meters / hour | 3500 cubic meters / hour | |

| Dimensions (mm) | 450*330*380 | 470*320*470 | 580*320*580 | |

| damper | power input | 6W | 6W | 6W |

| Open | exchange fresh air | exchange fresh air | exchange fresh air | |

| close | drying | drying | drying | |

| Dimensions (mm) | 480*320*120 | 630*560*120 | 720*640*125 | |

| Evaporator fan motor (2 units) |

power input | 250W/unit | 780W/unit | 780W/unit |

| Air volume | 4600 cubic meters / hour | 10500 cubic meters / hour | 2*10500m3/H | |

| Rotating speed | 1350 rpm | 1350 rpm | 1350 rpm | |

| hot air outlet | mm | 600*1100 | 650*1100 | 860*1485 |

| hot air return | mm | 690*1100 | 750*1100 | 1050*1450 |

| Size (L*W*H) | mm | 1650*960*1280 | 1720*1160*1280 | 2100*1460*1590 |

| net weight | Kilogram | 210 | 385 | 480 |

| gross weight | Kilogram | 240 | 420 | 540 |

Recommended dryer + drying oven

| dryer material | Galvanized steel (optional stainless steel) | ||

| Drying Chamber Materials | Polyurethane Both sides: Steel |

||

| heat source | 75% Air + 25% Electric | ||

| brand | Gimhae | ||

| model | JK03RD JK06RD JK12RD | ||

| Recommended dryer + drying chamber size | describe | Product capacity | Drying room size |

| One JK03RD dryer + drying room | 300Kg/batch | 3300*1900*2200mm | |

| One JK06RD dryer + drying room | 600Kg/batch | 6000*2800*2200mm | |

| One JK12RD dryer + drying chamber | 1000Kg/batch | 6000*3000*2200mm | |

| Two JK03RD dryers + drying chamber | 1300Kg/batch | 7000*2200*2200mm | |

| Two JK06RD dryers + drying chamber | 1500Kg/batch | 10000*2800*2200mm | |

| Two JK12RD dryers + drying chamber | 3500Kg/batch | 10000*3000*2200mm | |

Warm Tip: We can make any drying room size according to your requirements.

A. Payment Services

1. Wire transfer

2. L/C (only for container orders)

3, Western Union, (for sample order and parts)

B. Technical service

1, We calculate the capacity and recommend the best model.

2. We provide professional refrigeration technical support and electronic technical support for your installation, commissioning and operation.

3. We provide spare parts and technical support during and after the warranty period.

4, If you need, we will provide training courses for your workers in our factory.

3. After-sales service

1. Provide technical support for your installation, operation and maintenance.

2. One-year warranty, extended warranty can be paid.

3. Provide spare parts and technical support at the most economical price after warranty

-

Best quality 10kg 15kg freeze dryer food drying freeze dryer price household oil-free vacuum pump usa ready stock

-

Vacuum freeze dryer price

-

Household 6kg 8kg fruit food mini vacuum drying household freeze dryer freeze dryer with vacuum pump machine US spot

-

Mini Vacuum Freeze Dryer For Sale

-

Digital Display Multifunctional Combination 8 in 1 Heat Press Machine Sublimation Printing T-shirt Cup Tray Hat Printing

-

Vacuum drying machine, milk powder for vacuum drying

-

Factory price mini industrial vacuum food freeze dryer price

-

220V / 110V Household Professional Food Dehydrator Fruit Dryer

-

Stainless Steel Vacuum Chamber Vacuum Degassing Chamber Glass Cover Silicone for Evacuating and Protecting Food

-

2019 China Laboratory Industrial Small Freeze Dryer Price For Sale

Other Products

-

$500.00 / piece

$500.00 / piece -

$3000.00 / set

$3000.00 / set -

$3200.00 / set

$3200.00 / set -

$4000.00 / set

$4000.00 / set -

$6000.00 / unit

$6000.00 / unit