High Efficiency Clarifiers and Concentrates, Mining Concentrators

-

Supplier: Shandong Xinhai Mining Technology & Equipment Inc. -

Region: Shandong, China -

Contact: Ms Feifei Liu -

Price: $20000.00 / 1 - 2 sets

$19000.00 / 3 - 4 sets

$18000.00 / >=5 sets -

Min. Order: 1 set

| Production capacity: | 5-1400 tons/day | Dimensions (L*W*H): | depending on model |

| Certification: | ISO 9001, CE | Video external inspection: | if |

| Showroom location: | not any | After-sale service: | whole service life |

| type: | Mining Thickener | Applicable industries: | Energy and Mining |

| Marketing Type: | Popular products | Mechanical test report: | if |

| Supply capacity: | 55 sets per month | color: | client needs |

| Core parts warranty: | 1 year | Local service location: | not any |

| Key words: | Mining Concentration Tank | port: | Qingdao, China |

| application: | mining, mining | Thickener price: | Negotiable |

| brand: | Xinhai | Material: | Carbon steel |

| After-sales service provided: | Engineers can service machinery overseas, on-site installation, commissioning and training | Health status: | new |

| Warranty: | 1 year | payment terms: | letter of credit, wire transfer |

| Core components: | engine, motor | Install: | Technical support |

| capacity: | 15-2500t/d | Packaging Details: | Standard containers, in bulk or as customer's request |

| usage: | Sludge Mining Concentrate | Motor Type: | AC motor |

| place of origin; place of origin: | Shandong China |

Mining Concentration Tank

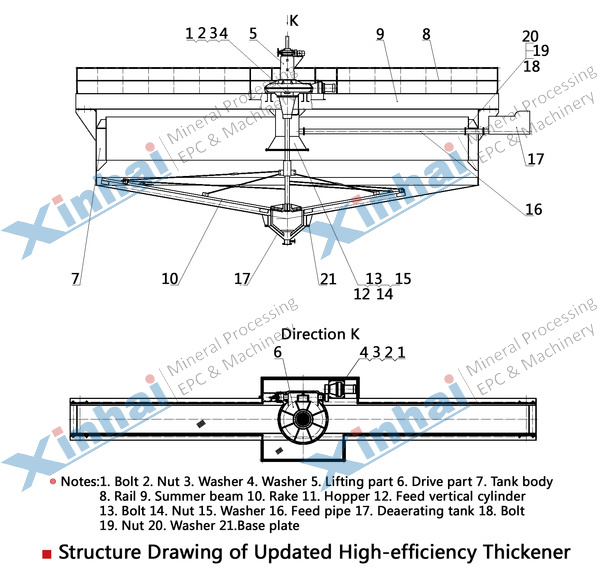

【Introduction】: Xinhai self-developed new high-efficiency concentration equipment.

【Capacity】: 5-1400t/d

【Improvement】: This thickener is a patented product of Xinhai, and the patent number is 201010521662.5. After the improvement, the capacity becomes larger, the overflow turbidity is low, and the discharge concentration is high

Mining Thickener

The outer overflow weir replaces the inner overflow weir, which increases the settlement area and is not easy to block;

The oblique feeding replaces the horizontal feeding, which solves the problem of clogging;

The static flow device reduces the material flow rate, making the overflow more uniform and the turbidity lower.

Concentration tank

The motor drives the vertical shaft to rotate, and the pulp of the feeding device flows into the feeding mixing barrel in the center of the tank. The solid material at the bottom of the tank is moved out of the center by the scraper; the overflow clarified by the static flow device flows out from the overflow weir outside the ring.

Model | Tank diameter (mm) | Groove depth (mm) | Subsidence area (square meters) | capacity (ton/day) | motor model | Motor Power (kilowatt) | Steel tank weight (kg) | weight (Kilogram) |

NZSG-2.5 | 2500 | 1850 | 4.9 | 5~22.4 | Y90L-6 | 1.1 | 1000 | 2225 |

NZSG-3A | 3000 | 1800 | 7 | 5 ~23.3 | Y100L-6 | 1.5 | 1664 | 3168 |

NZSG-3 | 3600 | 1800 | 10.2 | 5 ~28.5 | Y100L-6 | 1.5 | 2097 | 3680 |

NZSG-5 | 5000 | 2956 | 16 | 16~90 | Y90L-4 | 1.5 | 5160 | 8031 |

NZSG-6 | 6000 | 2956 | 28.3 | 98 | Y90L-4 | 1.5 | 5769 | 9200 |

NZSG-7 | 7000 | 3000 | 38.5 | 140 | Y112M-6 | 2.2 | 8800 | 13862 |

NZSG-8 | 8000 | 3318 | 50.2 | 185 | Y132S-6 | 3 | 12966 | 19158 |

NZSG-9 | 9000 | 3376 | 63 | 210 | Y132S-6 | 3 | 15418 | 21733 |

NZSG-12 | 12000 | 3600 | 113 | 370 | Y132S-6 | 3 | 25589 | 34823 |

NZSG-15 | 15000 | 3600 | 176 | 580 | Y132S-4 | 5.5 | 35800 | 54315 |

NZSG-18 | 18000 | 4400 | 255 | 960 | YCT200-4B | 7.5 | 52485 | 73588 |

NZSG-20 | 20000 | 4400 | 315 | 1400 | YCT200-4B | 7.5 | 59365 | 76312 |

-

Low cost mud water sludge thickener liquid thickener

-

Hua Center Transmission Concentrate Tailings Thickener Dehydration

-

Ex-factory price copper-iron-lithium ore sedimentation tank sludge thickener

-

Fully automatic mine tailings concentrate treatment mud sewage sludge dehydration high-efficiency thickener price

-

Sludge Collector Circular Settling Thickener Tank Sludge Scraper Peripheral Drive Sludge Classifier Thickener Price For Sale

-

Gold ore cyanide leaching plant gold ore concentrator

-

Factory price sedimentation tank NZS-3 slime thickener for sale

-

Tailings gold beneficiation high-efficiency thickener

-

mine iron ore dewatering thickener/slurry sludge thickener tank sedimentation tank

-

Low Price Sludge Thickening Tank Supplier

Other Products

-

$2555.00 - $2999.00 / set

$2555.00 - $2999.00 / set -

$24500.00 / set

$24500.00 / set