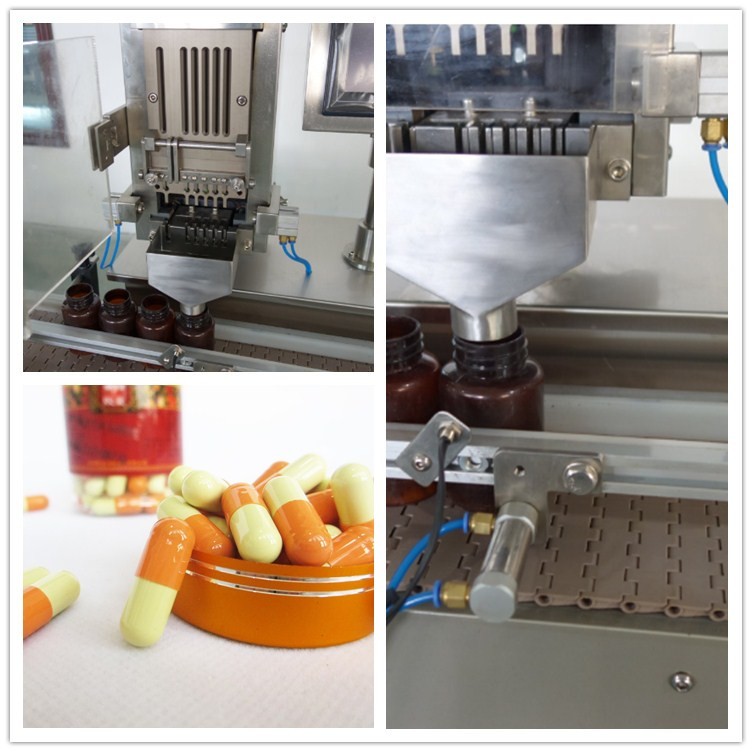

SN Top High Quality Medicinal Capsule Counting Machine

-

Supplier: Sinoped International (liaoning) Co., Ltd. -

Region: Liaoning, China -

Contact: Mr David Hua -

Price: $3000.00 /set -

Min. Order: 1 set

| usage: | capsule | Mechanical test report: | if |

| weight: | 90kg | product name: | Automatic counting machine |

| Applicable industries: | Food and Beverage Factory | feature: | counting capsules |

| Core components: | bearing | Warranty: | 1 year |

| Core Components Warranty: | 1 year | Video external inspection: | if |

| Marketing Type: | Hot Products of 2019 | Gross weight per piece: | 90.000 kg |

| Main selling point: | easy to operate | place of origin; place of origin: | China |

| Voltage: | 220V 50HZ | Dimensions (L*W*H): | 1200*500*1400mm |

| appropriate types: | Automatic counting machine | application: | 00-5# Capsule |

| type: | Stainless Steel Capsule Counter | Material: | Stainless steel |

| Showroom location: | not any | use: | Fill the capsule bottle |

| Power (W): | 1.2kW | brand: | Sinopec |

| Advantage: | easy to use | Sales unit: | single product |

| Capacity (pieces/hour): | 36000/hour | Weight (kg): | 120 |

| Single package size: | 120X50X140 cm | Health status: | new |

| Packaging Details: | export wooden box |

The equipment is a patented capsule intelligent high-precision automatic capsule counting machine. The model counting device can automatically realize the filling work of any number (odd, even, precise number of pieces). Small size, low noise and stable operation, it is an ideal choice for small and medium-sized pharmaceutical companies, health care product factories, hospital preparation rooms, and automatic filling equipment for several grains.

1) Vertical orbit compensation counting (patented technology), the particle number accuracy can reach 99.9%, avoiding a large amount of errors in traditional vibration or rotation errors.

2) Vertical track compensation count (patented technology), realize the number of bottled capsules to quickly set all the numbers in the same type of capsules, no need to change the mold, very fast and convenient.

3) The main engine adopts variable frequency speed regulation, which can be soft-started and the speed regulation is sensitive, reliable and stable, and can withstand a large starting torque.

4) The bottle conveying machine is of conveyor type, and the interface is reserved for the customer's later connection, which can quickly connect auxiliary equipment (bottle unscrambler, capping machine, etc.).

5) The control adopts touch screen man-machine interface PLC programmable controller technology, which can quickly set various parameters.

6) Light control technology automatically detects no bottle or no bottle and automatically alarms to minimize the waste of capsules.

7) All molds are designed with cylindrical pins, and it only takes 5 minutes to replace the molds, which is convenient and fast.

8) The drug contact parts are made of 304 stainless steel

Die change time | 5 minutes |

Ability to work | 20,000--40,000 capsules/hour |

Counting accuracy | 100% |

The right capsule size | 000#, 00L#, 00#, 0L#, 0#, 1#, 2#, 3#, 4#, 5# |

bottle diameter | 130mm |

power supply | 220V 50HZ 1.2kw |

compressed air | 0.03 cubic meters per minute 0.7Mpa |

Dimensions | 1200*500*1400mm |

machine weight | 90kg |

-

Semi-automatic electronic small desktop vitamin candy counter mini candy hard candy counting machine

-

Automatic line counting capsule machine small pill rainbow candy capsule tablet counter bottling machine

-

Cork counting machine SUS304 stainless steel material for food grade

-

Manual number of capsules 60 pieces at a time

-

16 Columns Automatic Medical Softgel Capsule Counter Pricing Pill Counting Bottling Filling Machine

-

Tablet capsule counting machine ZJS-A

-

Best Desktop Electronic Tablet / Capsule Counting Machine For Sale

-

automatic pill counter at best price

-

Automatic Capsule Tablet Pill Filling Counting Filling Machine

-

Desktop semi-automatic counter soy milk chip chewing gum gummy bear counter candy counting machine

Other Products

-

$12.50 / square meter

$12.50 / square meter -

$1890.00 / set

$1890.00 / set -

$10000.00 / set

$10000.00 / set -

$20989.00 / set

$20989.00 / set -

$1000.00 / set

$1000.00 / set -

$1000.00 / set

$1000.00 / set -

$2600.00 / set

$2600.00 / set -

$1000.00 / set

$1000.00 / set -

$8000.00 / set

$8000.00 / set