Brandt VSM 300 Series Shakers

-

Supplier: Dongying Lake Petroleum Technology Co., Ltd. -

Region: Shandong, China -

Contact: Mr Bing Xin -

Price: $80.00 / 2 - 99 pieces

$50.00 / >=100 pieces -

Min. Order: 2 pieces

| port: | China's main ports | Production capacity: | Do not |

| product name: | vibrating screen | weight: | 5KG |

| Marketing Type: | normal product | Dimensions (L*W*H): | Do not |

| application: | well controlled | Certification: | International Organization for Standardization |

| Local service location: | not any | Core Components Warranty: | Not available |

| Showroom location: | not any | feature: | Do not |

| Supply capacity: | 5000 pieces per month | model: | API100 |

| Key words: | Shale Shaker Munufacture | Health status: | new |

| Packaging Details: | Standard Export Packaging for Brandt VSM 300 Series Replacement Shakers | Applicable industries: | Energy and Mining |

| payment terms: | L/C,Western Union,T/T | Mechanical test report: | if |

| brand: | lake | Packaging Preview: | |

| place of origin; place of origin: | Shandong China | Warranty: | unavailable |

| Core components: | programmable logic controller | Voltage: | Do not |

| color: | required | type: | Compatible or steel frame |

| Video external inspection: | if |

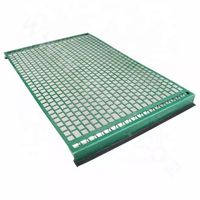

Replacement Shaker Screens for Brandt VSM 300 Series

1. Steel frame:

It is composed of two or three layers of 304 or 316 stainless steel wire cloth, and the steel back plate and the steel frame are combined together. Better filtration results are obtained due to different mesh sizes and pore sizes.

Bottom high-strength steel frame, support rods combined with medium tension screen cloth. Infinitely improve screen strength and battery life for better filtering effects. The number of meshes varies from 20 to 325. The whole cloth is divided into independent facets to prevent some excessive expansion and damage, and repair the damage together with the special rubber plug, which can save the time of replacing the screen, improve the efficiency and reduce the cost.

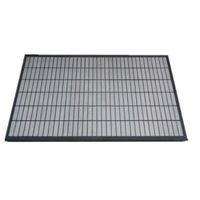

2. Compatible framework:

The composite frame vibrating screen is made of polyurethane material frame and two or three layers of 304 or 316 stainless steel wire cloth. The main features are as follows:

High-strength plastic frame and moderately tensioned screen cloth, from a reliable whole, greatly improves tolerance.

The screen is divided into several independent small cloths to prevent excessive expansion of local damage. At the same time, it is equipped with a special rubber stopper to repair the damage, saving time and reducing the cost of use.

The quick wedge tensioning device makes the screen installation more convenient and saves the time for half-machine replacement.

The excellent polyurethane material frame enhances corrosion resistance, has good stock absorption and prolongs the life of the screen.

|

Brandt series screen |

|

|

network |

API20---API325 |

|

aspect |

Length: 1251 mm (49 1/5 inches) |

|

Width: 635 mm (24 4/5 inches) |

|

|

weight |

Steel frame: 13kg (28.6lb) |

|

Composite frame: 12kg (26.4lb) |

|

|

screen layer |

2 or 3 floors |

|

wire mesh material |

S.S304 ,S.S316 (can be customized) |

|

frame material |

carbon steel, composite |

|

Swaco Mongoose Series Screen |

|

|

network |

API20---API325 |

|

aspect |

Length: 1165 mm (45 9/10 in) |

|

Width: 585 mm (23 inches) |

|

|

weight |

Steel frame: 13kg (28.6lb) |

|

Composite frame: 12kg (26.4lb) |

|

|

screen layer |

2 or 3 floors |

|

wire mesh material |

S.S304 ,S.S316 (can be customized) |

|

frame material |

carbon steel, composite |

-

API vibrating screen high-quality solids control equipment for oilfield trailer-mounted drilling rigs

-

Vibrating screen mesh for oilfield solids control equipment

-

API 304/306 stainless steel frame shale shaker for mud filtration

-

Mud vibrating screen solids control system vibrating screen

-

JZCQ -240 series oilfield control system vacuum degasser

-

API Standard Oil Well Drilling Fluid Solid Control Vacuum Degasser

-

oilfield drilling nov brandt vsm 300 vibrating screen factory price

-

Manufacturer of high quality decanter centrifuges

-

API Standards Rigid Control System Twin Impeller Mud Agitator Professional Mixer

-

Shaker

Other Products

-

$800.00 / piece

$800.00 / piece -

$800.00 / piece

$800.00 / piece -

$2.00 / set

$2.00 / set -

$60.00 - $70.00 / set

$60.00 - $70.00 / set -

$1000.00 / set

$1000.00 / set -

$621.94 - $675.00 / set

$621.94 - $675.00 / set -

$140.00 / piece

$140.00 / piece -

$35000.00 / set

$35000.00 / set -

$800.00 / piece

$800.00 / piece -

$140.00 / piece

$140.00 / piece