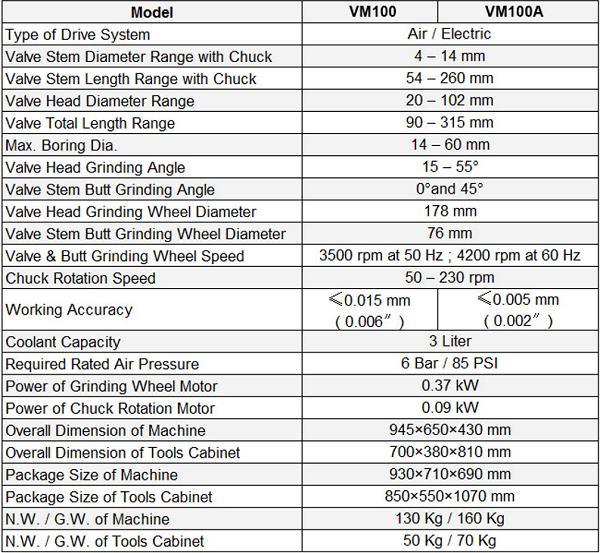

VM100 VM100A High Precision Valve Grinding Machine Valve Grinder Grinding Machine

-

Supplier: Xi'an Premier Machine Tools Co., Ltd. -

Region: Shaanxi, China -

Contact: Mr Eric Hong -

Price: $2500.00 /set -

Min. Order: 1 set

| Supply capacity: | 30 sets per month | Local service location: | not any |

| Voltage: | 220V | Core components: | engine |

| payment terms: | L/C, T/T, we choose different payment methods accordingly | Health status: | new |

| Warranty: | 1 year | Main selling points: | high accuracy |

| Video shipment inspection: | if | Certification: | ISO9001 |

| type: | Cylindrical grinder | Showroom location: | not any |

| After-sales service provided: | Online support, video technical support | Weight (kg): | 160 |

| port: | Shanghai | maximum. Grinding diameter: | 14mm |

| Origin: | Shaanxi, China | maximum. Grinding length: | 315mm |

| After warranty service: | Video technical support, online support | Power (kW): | 0.37 kW |

| CNC or not: | normal | Dimensions (L*W*H): | 930*710*690mm |

| Marketing Type: | 2019 Hot Products | Packaging Details: | plywood case |

| Surface roughness (μm): | 666 microns microns | brand: | prime machine |

| Applicable industries: | Manufacturing plants, machinery repair shops | Mechanical test report: | if |

| Core component warranty: | 1 year |

High precision valve grinder

Model: VM100/VM100A

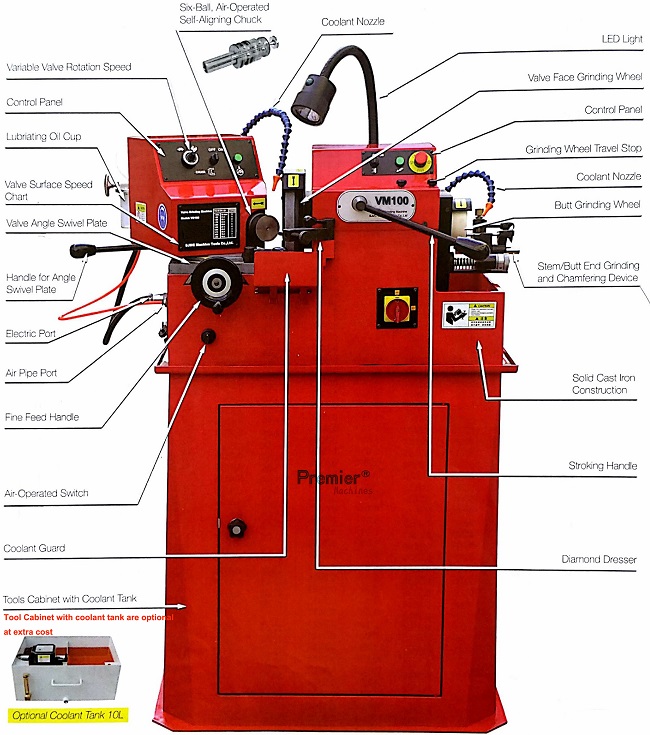

Valve grinder model: VM100 series can complete the following tasks within five minutes: Clamp the valve stem to maintain instant high-precision positioning; Finely grind the valve cone surface, the roundness can reach 0.005mm, and the smoothness can reach Ra0.32. The whole process is simple and perfect, very easy to use the machine, no special training is required, you can do that perfect job, depends on the 2×3 ball high precision pneumatic chuck. The VM100 series is the new standard for speed and precision in valve grinding.

1) Pneumatic, six-ball chuck design, perfect centering grinding, it only takes 5 minutes from clamping to fine grinding, and can get very good roundness and smoothness.

2) Variable valve speed allows the operator to adjust surface speed when using different sized valves.

3) The grinding wheel moves on a high-precision dovetail guide rail, making manual scraping super smooth and absorbing vibration effectively.

4) The Valve Steam Depth Stop is a practical device, especially when you need to machine multiple identical valves and have the valves milled to the exact same length.

5) The cast iron base reduces vibration and is durable.

6) Centralized lubrication system to avoid cumbersome manual multi-point refueling.

7) The valve head grinding wheel and valve steam grinding wheel are equipped with a diamond dresser, which is very convenient for dressing the grinding wheel.

8) The optional tool cabinet has an additional 2-liter coolant tank. Of course, the space is large enough to change to a larger coolant tank if you want more cooling water.

9) The V-bracket of the stem end/butt end lapping unit allows all valves in a group to be lapped to the same distance from the valve seat to the stem end - critical for overhead cam cylinder heads. The exact amount of material removed from the end of the stem can be measured using a micrometer adjustment system.

-

MK1320 MK1332 CNC Cylindrical Grinder

-

M1420 Universal cylindrical grinder

-

3mm-13mm CNC Automatic Drill Bit Groove Grinder Drill Bit Groove Grinder

-

Used Chinese Grinder Cylindrical Grinder M1432Bx2000mm High Quality

-

Metal Circular Saw Blade Grinder

-

blade grinder / Hoja de maquina amoladora /

-

M1308 300mm Cylindrical Grinder

-

China supplier 250 (220V/50HZ) woodworking cutting saw blade grinder

-

Small cylindrical grinder M1408/cheap cylindrical grinder/grinder

Other Products

-

$600.00 / set

$600.00 / set -

$30.00 / piece

$30.00 / piece -

$1100.00 / set

$1100.00 / set -

$2500.00 / set

$2500.00 / set -

$5000.00 / set

$5000.00 / set -

$10000.00 / set

$10000.00 / set -

$4000.00 / set

$4000.00 / set