DMTC DT30/DT40/DT50 Inclined Bed CNC Lathe China CNC Lathe Horizontal Inclined Bed CNC Lathe Cheap Price

-

Supplier: Dalian Dahui Machine Tool Co., Ltd. -

Region: Liaoning, China -

Contact: Mr Hui Liu -

Price: $18000.00 / 1 - 1 sets

$16200.00 / 2 - 2 sets

$15000.00 / >=3 sets -

Min. Order: 1 set

Product details

| maximum. Cutting diameter (shaft/disk): | 280/300mm | Marketing Type: | normal product |

| Package preview: | maximum. Work piece length (mm): | 300/280 | |

| Main selling points: | multifunctional | Certification: | ISO9001 |

| payment terms: | L/C, D/P, D/P, T/T | Health status: | new |

| Year: | 2022 | Travel (Z axis) (mm): | 300 mm |

| Repeatability (X/Y/Z) (mm): | ±0.003 | Voltage: | 380V |

| Mechanical test report: | if | Core components: | engine |

| Bed width (mm): | 300 mm | maximum. Cut length: | 300 |

| Travel (X axis) (mm): | 155mm | Number of spindles: | twin |

| Spindle bore diameter (mm): | 63 | Chuck size: | 6 intermediate solid |

| Dimensions (L*W*H): | 2360*2510*1835mm | Weight (kg): | 4000 |

| Spindle torque: | 58/113 | Packaging Details: | Long-term cooperation wooden bag |

| Processing capacity: | relaxing work | Spindle speed range: | 45~5000 rpm |

| Spindle motor power (kW): | 11/15 | Video shipment inspection: | if |

| Origin: | Liaoning, China | Tool Station: | 12 |

| Cutting feed rate: | X 0~9000 Z 0~9000mm/min | Positioning accuracy (mm): | ±0.008 |

| Core component warranty: | 1 year | Spindle front bearing diameter: | 100mm |

| Warranty: | 1 year | brand: | DMTC |

| CNC system: | FANUC | maximum. Turning diameter: | 480mm |

| model: | DT30/DT40/DT50 | type: | Turning Center |

| maximum. Spindle speed (rpm): | 5000 rpm | Applicable industries: | Machinery repair shop, manufacturing plant |

| Number of axes: | 2 | Showroom location: | not any |

| Fast movement speed: | X 30 Z 30 m/min |

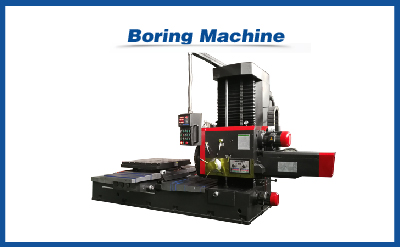

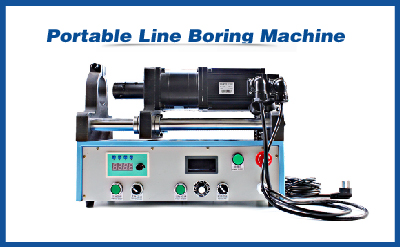

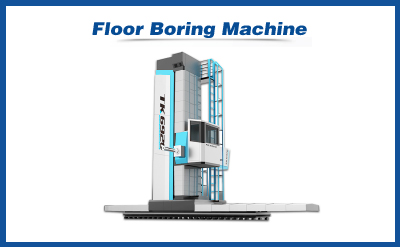

Related Products

Products Recommended

Product Description

project | unit | DT-30H | DT-40H | DT-50H | |||||||||||

Processing range | maximum. Turning diameter | mm | Φ480 | Φ580 | Φ680 | ||||||||||

maximum. Cutting diameter (shaft/disk) | mm | Φ280/Φ300 | Φ350 | Φ450 | |||||||||||

maximum. cutting length | mm | 300 | 555, 1055 (Italian Deep Sword Tower) | 555, 1055 (Italian Deep Sword Tower) | |||||||||||

mm | 475, 975 (Taiwan Liuxin Dao Pagoda)* | 475, 975 (Taiwan Liuxin Dao Pagoda)* | |||||||||||||

mm | 445, 945 (Wenling Sanhe Dota)* | 445, 945 (Wenling Sanhe Dota)* | |||||||||||||

Spindle | Spindle head type | —— | ISOA2-5 standard | ISOA2-6 optional | ISO A2-6 | ISO A2-8 | ISO A2-8 | ||||||||

Chuck size | —— | 6″ middle solid | 8″ medium solid | 8″ medium solid | 10″medium solid | 10″medium solid | |||||||||

Spindle speed range | rpm | 45~5000 | 45~4500 | 35~4000 | 35~3500 | 35~3500 | |||||||||

Spindle front bearing diameter | mm | Φ100 | Φ110 | Φ130 | Φ130 | ||||||||||

Spindle through hole diameter | mm | Φ63 | Φ70 | Φ87 | Φ87 | ||||||||||

Through rod diameter (when optional hollow chuck and cylinder) | mm | Φ45 | Φ47 | Φ51 | Φ73 | Φ73 | |||||||||

Spindle power | kilowatt | 7.5/11 | 11/15 | 11/15 | 15/18.5 | ||||||||||

Spindle torque | cow rice | 58/113 | 105/140 | 105/140 | 143/236 | ||||||||||

feed drive | move fast | m/min | X 30 Z 30 | X 30 Z 30 | X 30 Z 30 | ||||||||||

Cutting feed rate | mm/min | X 0~9000 Z 0~9000 | X 0~9000 Z 0~12000 | X 0~9000 Z 0~12000 | |||||||||||

X-axis max travel | mm | X 165 | 215 | 265 | |||||||||||

Z-axis maximum travel | mm | Z 300 | 555, 1055 (Italian Deep Sword Tower) | 555, 1055 (Italian Deep Sword Tower) | |||||||||||

475, 975 (Taiwan Liuxin Dao Pagoda)* | 475, 975 (Taiwan Liuxin Dao Pagoda)* | ||||||||||||||

445, 945 (Wenling Sanhe Dota)* | 445, 945 (Wenling Sanhe Dota)* | ||||||||||||||

Machine Tool Accuracy Standards | positioning accuracy | mm | (X) 0.005 (Z) 0.005 (C) 44″ | (X) 0.005 (Z) 0.007 (600) 0.008 (1000) | (X) 0.005 (Z) 0.007 (600) 0.008 (1000) | ||||||||||

(C)31” | (C)31” | ||||||||||||||

repeatability | mm | (X) 0.003 (Z) 0.003 (C) 18″ | (X) 0.003 (Z) 0.004 (600) 0.005 (1000) | (X) 0.003 (Z) 0.004 (600) 0.005 (1000) | |||||||||||

(C)13” | (C)13” | ||||||||||||||

deficit | mm | 0.007 | (X) 0.007 (Z) 0.007 (600) 0.008 (1000) | (X) 0.007 (Z) 0.007 (600) 0.008 (1000) | |||||||||||

(C)13” | (C)13” | ||||||||||||||

Processing roundness | mm | 0.004 | 0.004 | 0.004 | |||||||||||

Processing cylindricity | mm | 0.012 | 0.012 | 0.012 | |||||||||||

Processing flatness | mm | 0.0135 | 0.0135 | 0.0135 | |||||||||||

Refer to the inspection of Part 4 of GB/T16462.4-2007 "Inspection Conditions for CNC Lathes and Turning Centers" Positioning accuracy and repeatability of linear and rotary axes". | |||||||||||||||

Machine tool accuracy (domestic power turret and spindle encoder) | positioning accuracy | mm | —— | (X) 0.005 (Z) 0.007 (600) 0.008 (1000) | (X) 0.005 (Z) 0.007 (600) 0.008 (1000) | ||||||||||

(C)63” | (C)63” | ||||||||||||||

repeatability | mm | —— | (X) 0.003 (Z) 0.004 (600) 0.005 (1000) | (X) 0.003 (Z) 0.004 (600) 0.005 (1000) | |||||||||||

(C)25” | (C)25” | ||||||||||||||

deficit | mm | —— | (X) 0.007 (Z) 0.007 (600) 0.008 (1000) | (X) 0.007 (Z) 0.007 (600) 0.008 (1000) | |||||||||||

(C)25” | (C)25” | ||||||||||||||

Processing roundness (part size) | mm | —— | 0.004(φ80) | 0.004(φ80) | |||||||||||

Processing cylindricity (part size) | mm | —— | 0.012(φ80) | 0.012(φ80) | |||||||||||

Machining flatness (part size) | mm | —— | 0.0135(φ200) | 0.0135(φ200) | |||||||||||

Refer to the inspection of Part 4 of GB/T16462.4-2007 "Inspection Conditions for CNC Lathes and Turning Centers" Positioning accuracy and repeatability of linear and rotary axes". | |||||||||||||||

knife tower | Number of turret stations | —— | 12 stations | 12 stops | 12 stations | ||||||||||

Tool change method | —— | According to the shortest path, any tool change | According to the shortest path, any tool change | According to the shortest path, any tool change | |||||||||||

Tool change time (adjacent/furthest) | Second | 0.31/0.76 (with positioning lock) | 0.31/0.78 (without positioning lock) (Italian Deep Sword Tower) | 0.31/0.78 (without positioning lock) (Italian Deep Sword Tower) | |||||||||||

0.23/0.6 (without positioning lock) | 0.49/0.96 (with positioning lock) (Italian Deep Sword Tower) | 0.49/0.96 (with positioning lock) (Italian Deep Sword Tower) | |||||||||||||

Shank size | mm | 20×20 | 25×25 | 25×25 | |||||||||||

Inner Hole Shank Size | mm | Maximum φ32 | Maximum φ40 | Maximum φ40 | |||||||||||

Electric tool drive motor power | kilowatt | 3.7/5.5 | With system configuration | With system configuration | |||||||||||

Power Tool Motor Torque | cow rice | 17.7 | With system configuration | With system configuration | |||||||||||

maximum. Live Tool Speed | rpm | 4000 | 5000 (Italian Deep Sword Tower) | 5000 (Italian Deep Sword Tower) | |||||||||||

4000 (Taiwan Six Hearts Tower)* | 4000 (Taiwan Six Hearts Tower)* | ||||||||||||||

4000 (Wenling Sanhe Dota)* | 4000 (Wenling Sanhe Dota)* | ||||||||||||||

maximum. Power Tool Drilling Capabilities | mm×mm/u | φ16×0.2 | φ22×0.2 | φ22×0.2 | |||||||||||

maximum. Live Tool Tapping Capability | mm x mm | M12×1.75; M18×1 | M16×2; M30×1.5 | M16×2; M30×1.5 | |||||||||||

maximum. Power Tool Milling Capabilities | mm×mm×mm/min | 22×10×40 (diameter*CDX*cutting speed) | 25×15×40 (diameter*CDX*cutting speed) | 25×15×40 (diameter*CDX*cutting speed) | |||||||||||

Tailstock | maximum. stroke | mm | 350 | 500/960 | 500/960 | ||||||||||

Tailstock sleeve diameter | mm | Φ70 | Φ85 | Φ85 | |||||||||||

Tailstock sleeve travel | mm | 120 | 140 | 140 | |||||||||||

Tailstock sleeve thrust | no | 900~1800 | 940~2700 | 940~2700 | |||||||||||

Mandrel taper | —— | —— | MT.NO.5 | MT.NO.5 | |||||||||||

Machine Dimensions and Weight | Machine size | mm | 2360×2510×1835 (without chip conveyor) | 2922×1900×2010 (600 without chip conveyor) | 2922×1900×2010 (600 without chip conveyor) | ||||||||||

3422×1900×2010 (1000 without chip conveyor) | 3422×1900×2010 (1000 without chip conveyor) | ||||||||||||||

machine weight | Kilogram | 4000 | 5300/6300 | 5500/6500 | |||||||||||

Note: When the rear chip conveyor is configured, the width increases by 1190; the length of the side chip increases by 1190 Conveyor configured | |||||||||||||||

Our advantage

VIEW MORE

You may like

-

Car lathe rim aluminum alloy rim diamond cutting machine rim refurbishment CNC wheel straightening repair machine

-

Diamond Cutting Polishing Machine Alloy Wheel Restoration CNC Lathe

-

CE Approved Wheel Restoration Diamond Cut Horizontal Lathe CNC Machine For 18' 19' 20' 22' 24' Forged Wheels

-

Low Cost Horizontal Precision Metal Lathe Machine Engine Lathe

-

CNC Slant Bed Lathes

-

Horizontal CNC lathe, Milling Machine

-

T2S500 German Technology High Quality Low Price Inclined Bed CNC Lathe Machine Tool CNC Machinery Wholesale Supplier Manufacturer

-

Mini CNC Lathe CK0632A Hot Selling Mini CNC Lathe Micro CNC Lathe

-

China CK210 Mini CNC Lathe

-

Taiwan technology inclined bed CNC lathe price

Other Products

-

$10500.00 - $16500.00 / set

$10500.00 - $16500.00 / set -

$356500.00 - $390000.00 / set

$356500.00 - $390000.00 / set -

$2954.00 / set

$2954.00 / set -

$47385.00 / set

$47385.00 / set -

$60000.00 / set

$60000.00 / set