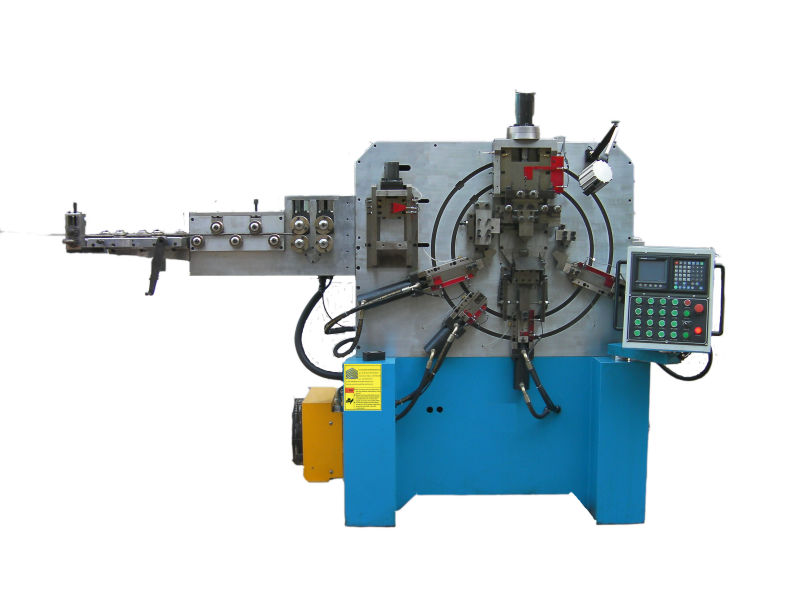

Automatic hydraulic wire bending machine

-

Supplier: Guangzhou DuroWelder Limited -

Region: Guangdong, China -

Contact: Ms Kalen Lee -

Price: $1.00 /set -

Min. Order: 1 set

| Video shipment inspection: | if | Applicable industries: | Building materials store, machinery repair shop, manufacturing plant, household |

| Mechanical test report: | if | Warranty: | 1 year |

| Supply capacity: | 50 sets per month | Origin: | Guangdong, China |

| Health status: | new | port: | Guangzhou, Shenzhen, Hong Kong |

| Key words: | Wire bending machine | Showroom location: | not any |

| After warranty service: | Video technical support, online support | Local service location: | not any |

| Packaging Details: | Wooden box, steel profile structure box | payment terms: | T/T, Western Union |

| brand: | hard welder | Marketing Type: | New Products 2020 |

| After-sales service provided: | Video technical support, online support |

Automatic hydraulic wire bending machine

Automatic Metal Strip Wire Forming Machine

The main features of the equipment:

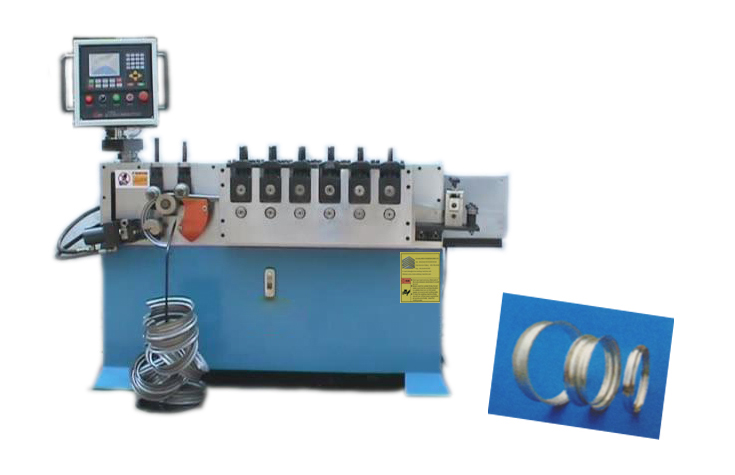

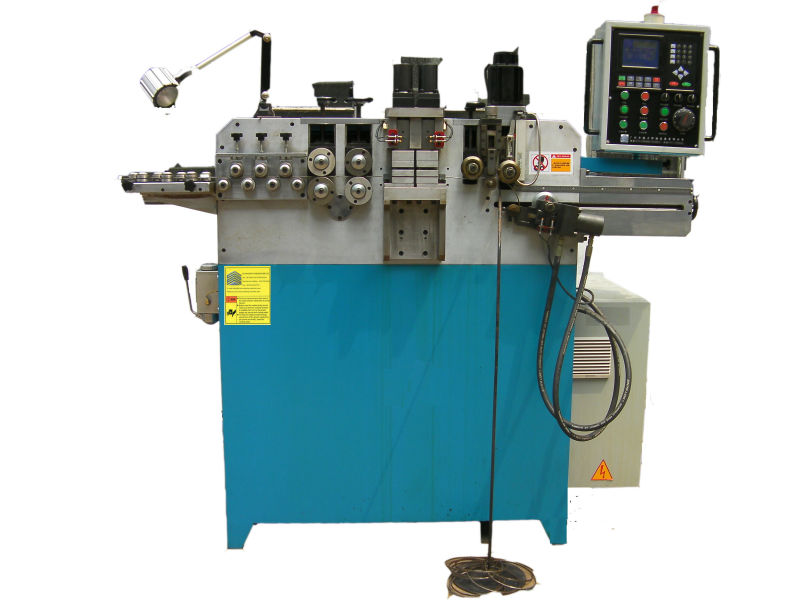

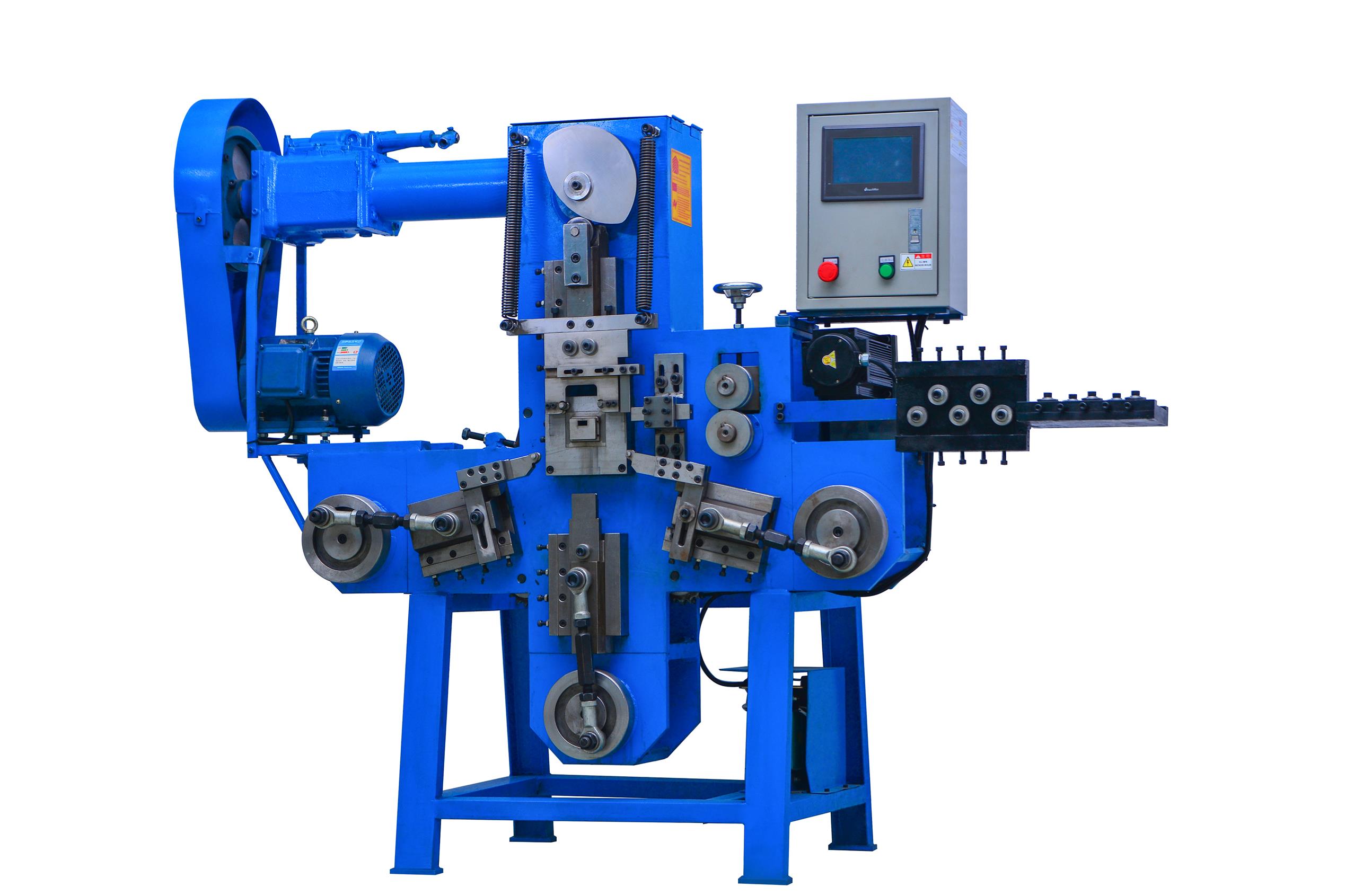

1 Automatic strip and wire forming machine, also known as wire bending machine, is mainly used to bend metal wire or metal strip into various 2D or 3D shapes.

2 There are two models: cam type and hydraulic type.

Cam type bending machine, with high speed and high efficiency, is mainly used to bend small-diameter wires and thinner strips into various simple shapes.

The hydraulic bending machine can bend metal wires and strips into arbitrary shapes, especially suitable for bending large-diameter wires and large-thickness strips into various two-dimensional (2D) or three-dimensional (3D) complex shapes.

3 The whole process is completed automatically, and it can also be equipped with a punching function.

4 Widely used in decoration, lighting, handicrafts, various hardware manufacturing and other industries, such as forming and bending of metal wires and strips such as clothes hooks, key chains, refrigerator racks, stainless steel fruit baskets, etc.

The main technical parameters:

|

device name |

model. |

Wire diameter |

cross-sectional area |

Maximum processing length |

productivity (pcs/min) |

strength |

|

Cam Type Metal Forming Machine |

CFM3 |

Φ1-3mm |

≤7.0mm2 |

180mm |

40-90 |

1.1KW |

|

CFM4 |

Φ1-4mm |

≤12.6mm2 |

220mm |

40-90 |

1.5KW |

|

|

CFM5 |

Φ1.5-5mm |

≤19.6mm2 |

320mm |

30-90 |

2.2KW |

|

|

CFM7 |

Φ1.5-7mm |

≤38.5mm2 |

400mm |

30-90 |

3.0KW |

|

|

Hydraulic Metal Forming Machine |

high frequency 6 |

Φ1-6mm |

≤T2*W20mm |

500mm |

20-40 |

10KW |

|

HF 8 |

Φ1-8mm |

≤T3*W30mm |

1000mm |

20-30 |

14KW |

-

Customized Cartoon Coaster Keychain USB PVC Oven Coaster Baking Machine Decorative Label

-

Smart Pvc Keychain Machine Heating Rubber Oven Drying and Cooling Keychain

-

Hot Sale Free Sample Waterproof Drag Chain Cable Drag Chain 120mm

-

China Foshan Factory Supply Daily Porcelain Automatic Production Line Design and Manufacture Daily Porcelain Production Line

-

Stainless Steel Pot Stamping Equipment - Hydraulic Deep Drawing Press 250 Tons

-

Wheelbarrow factory: Wheelbarrow box production line.

-

Ungar Auto-Matic press for the production of single-use aluminium foil containers

-

Automatic disposable wooden cutlery machine to make spoon machinery

-

Factory Customized CNC Machining Service for Home / Office application instrument (Face Recognition Machine part)

-

wire hanger automatic wire paper tube hanger making machine (strut hanger)

Other Products

-

$3000.00 / set

$3000.00 / set -

$20000.00 / set

$20000.00 / set -

$1000.00 / set

$1000.00 / set -

$1.00 / set

$1.00 / set -

$1.00 / set

$1.00 / set -

$500.00 / set

$500.00 / set -

$1000.00 / set

$1000.00 / set -

$200.00 / set

$200.00 / set