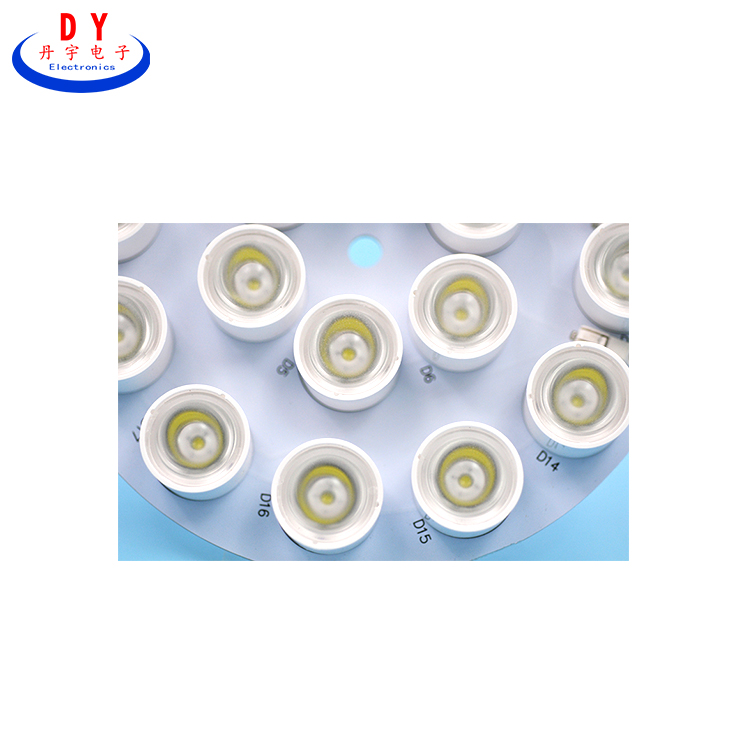

Custom Aluminum LED PCB Manufacturer Pcba High Temperature Resistant Circuit Board Lamp Tube LED Bulb Mcpcb

-

Supplier: Shenzhen Danyu Electronics Co., Ltd. -

Region: Guangdong, China -

Contact: Mr Peter Gui -

Price: $0.60 / 1 - 499 pieces

$0.40 / >=500 pieces -

Min. Order: 1 piece

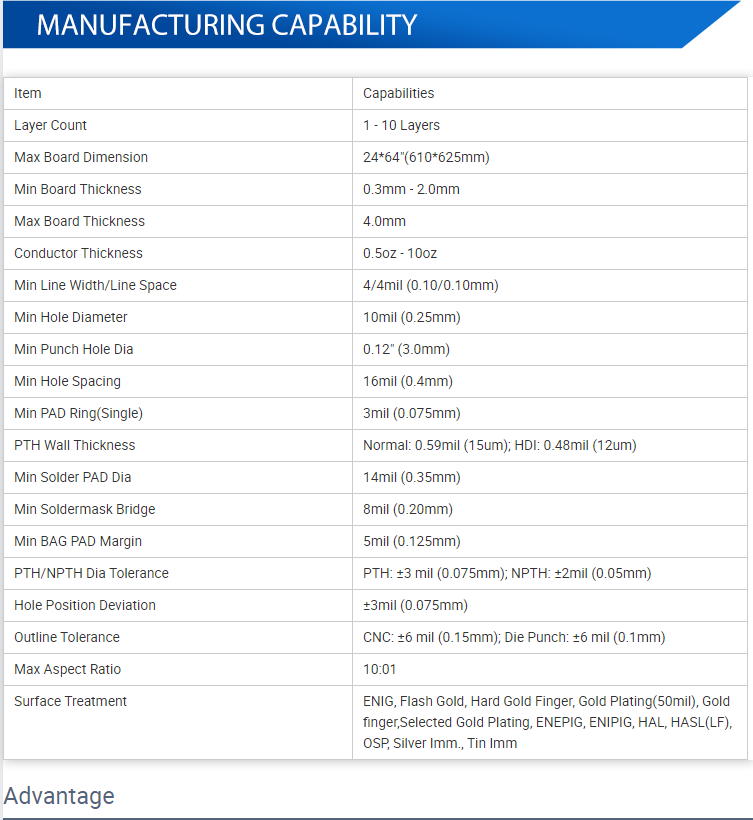

| Packaging Details: | 50 pcs/box, 1 box/carton | Substrate: | aluminum |

| Plate thickness: | 2.00mm | model: | Bad 21173 |

| minute. line width: | 0.15 mm | Certificate: | ISO9001/ISO16949/UL/RoHS |

| Board size: | 30mm*30mm | Package preview: | |

| payment terms: | Western Union, T/T | MOQ: | 1 |

| Copper thickness: | 1 oz | Origin: | Guangdong, China |

| minute. Hole size: | 0.5 mm | type: | Double-sided aluminum core PCB, double-sided aluminum core PCB |

| layer: | 1 story | Surface treatment: | open source software |

| brand: | Danyu Electronics | product name: | Manufacturer PCBA high temperature resistant |

| minute. Line spacing: | 0.15 mm | port: | Yantian |

PCB/PCBA Manufacturer Custom Metal Core PCB

1. Can you tell me the minimum specification for 2-layer metal core PCB to be successfully manufactured in your factory? i.e. minimum thickness etc.

1) Minimum aperture 0.5mm

2) The minimum distance between the hole edge and the hole edge is 1.5mm

3) Minimum line width and spacing: 10Z(0.2mm)/20Z(0.25mm)

4) Minimum final plate thickness: 0.8mm

2. Are you a UL certified manufacturer?

Yes, we are a UL listed manufacturer, our UL is E475635. We have passed uL certification

3. Can aluminum be used as a sink base?

In fact, only copper can be used for the base of the sink.

As you can see the following manufacturing steps, the SinkPad will use a copper etching solution to etch the copper substrate into bosses, then hollow out the double-layer FR4 PCB and laminate with the bosses.

But as far as the current technical conditions are concerned, since aluminum or aluminum alloy cannot directly react with acid, the reaction process is too complicated and difficult to control, which will increase the difficulty of etching the LED pad platform. Considering the scrap rate, the process of etching LEDs on the aluminum pad platform is more complicated, and the overall cost is higher.

4. Can you provide links to these white papers explaining the technical comparison between FR4 and MCPCB?

There are two differences between MCPCB and FR4, one is thermal conductivity, and the other is cost. (The price of MCPCB is generally 3-4 times that of FR4 PCB)

MCPCBs are used instead of traditional FR4 PCBs because of their ability to efficiently dissipate heat away from components. This is achieved by using thermal

A conductive dielectric layer that acts as a thermal bridge between the IC components and the metal backplane. Heat is conducted from the package through the metal core to an additional heat sink.

On FR4 boards, heat will remain stagnant if not transferred through a local heatsink.

According to Avago's white paper (AV01-0615EN.pdf), an MCPCB with a 1W LED was maintained at around 25C ambient, while the same 1W LED on an FR4 board reached 12C above ambient.

5. Is the back of the PCB coated with topcoat? Or just bare copper?

Usually the copper is exposed on the backside, if you want to paint ENEPIG paint on the backside of the PCB is also ok, but the cost will be higher than bare copper, because you know the price of gold will increase.

So it's better to expose it.

6. What is the thickness of ENEPIG metal layer?

You are right, ENEPIG is great for wire bonding. :-) The wire bonds need to be 3u" thick.

7. How thick is the dielectric interlayer between the top copper foil and the substrate?

75-100 microns

8. Can a thicker dielectric layer be requested?

Yes, it can be thicker, is 150um ok?

9. This will be used in LED (90+W) lighting products. Which dielectric layer do you recommend?

Considering the higher LED power, 3W.mk or 2W/mk is better than 1W/mk

10. Can you do bevel and chamfer features in metal core technology?

Yes, we can do it, we have done it for other customers.

What is the tolerance?

1. We can chamfer in two ways...

Option A: Milling machine. The tolerance is +/-0.15 to +/-0.2mm, but the chamfered surface will be rough.

..

Plan B: fine carving process, tolerance +/-0.1MM, but the price will be higher than Routermachine processing

11. What is the standard dielectric (Tpreg) thickness used for aluminum board (MCPCB)?

Usually the standard dielectric thickness is 75um or 100um.

12. Is it possible to reduce or increase the thickness of the dielectric?

What thickness do you need? If the dielectric is too thin, it can easily be broken down.

13. Is 2.0 W/(m*K) the highest thermal conductivity possible for the aluminum plate or can you provide higher thermal conductivity?

No, we can also offer a thermal conductivity of 3.0 W/(m*K).

14. For 1 layer SinkPAD, is it possible to do HASL (lead-free) surface treatment?

For 1 layer SinkPAD we don't recommend doing HASL (lead free), please let me clarify for you.

1) As you can see stacked up, the Sink PAD PCB laminate is pure film and the adhesion is not very good, so there is a risk of delamination if doing HASL (lead-free).

2) HASL (lead-free) has a film-removing process, and the potion will react with copper.

So please reconsider OSP and feel free to contact me if you have further questions.

|

|

|

| $0.5 | $0.6 |

$0.3 |

|

|

|

| $0.8 | $1.0 | $0.1 |

-

Seplos Apexium RS485 RS45 Adapter to USB RS485 RJ485 Converter with Ethernet CD

-

US EU JK-B2A24S20P Active Balance BMS 8S 12S 16S 20S 24S 200A 24V 48V 72V BT Can UART Communication Lifepo4 Battery JK Smart BMS

-

Led TV Smart Board Keyboard PCB Custom Fr4 Pcb Manufacturer High Quality Line Width Metal Detector PCB Circuit Board

-

Single-sided PCB board metal core PCB PCB Mcpcb aluminum substrate printed circuit board for linear light

-

Docan Tech Jikong BMS JK B2A24S15P 8-24S 150Ah Smart BMS Balance Board Protection Lifepo4 Battery Cell DIY JK BMS

-

Street light source factory autobiography 3W 2oz copper thick aluminum core PCB

-

4.3 Inch JK LCD Display 2.5 Inch LCD Touch Screen Lifepo4 LTO LED Display Lithium Ion BMS Monitor

-

Shenzhen Fast Cheap EMS OEM Prototype PCB Supplier Manufacturer Custom Electronic Circuit Board Assembly PCBA Design Service

-

custom led ring pcb pcb assembly smd led pcb board manufacturer

-

Hot selling recommended pcb manufacturers pcb&pcba electronic circuit board control board LED light bar

Other Products

-

$1.49 - $1.99 / piece

$1.49 - $1.99 / piece -

$0.30 - $0.50 / piece

$0.30 - $0.50 / piece