Erw MS pipe making machine for manufacturing steel pipe metal pipe production line manufacturer

-

Supplier: Shanghai Honcang Industrial Limited -

Region: Shanghai, China -

Contact: Mr SHAWN XU -

Price: $320000.00 /unit -

Min. Order: 1 unit

| Applicable industries: | Home use, farms, construction projects, building material stores, manufacturing plants | Place of origin: | China |

| Main selling points: | competitive price | Supply capacity: | 200 units per year |

| High frequency system: | Samick brand/Thermatool brand | Core components: | PLC, engine, bearing, gearbox, motor |

| Mechanical test report: | if | payment terms: | Letter of credit, wire transfer |

| Core component warranty: | 1 year | thickness: | 0.4mm-8.0mm |

| Showroom location: | not any | Weight (kg): | 55000 |

| Video outbound inspection: | if | Cutting system: | Saw blade cutting/high speed steel blade cutting |

| Warranty: | 1 year | Pipe diameter: | 8mm~219mm |

| Packaging details: | According to customer requirements; main engine shipping container; spare parts wooden box high frequency welded steel pipe unit welded steel pipe production line | Health status: | new |

| Control System: | Siemens/Taiwan PLC control system; | port: | Shanghai Port |

| Marketing type: | normal product | Type of machine: | Pipe production line |

ERW pipe making machine | Slitting machine | Cutting line to length |

Steel forming machine | Roll film production line | Coil material color coating line |

Why choose us?

1.30 years of focus on research and development of metal processing equipment

2.15 years of export experience, serving hundreds of customers in 40 countries

3. Top engineering team and advanced production technology bring maximum returns to customers.

4.24-hour online service, excellent service system

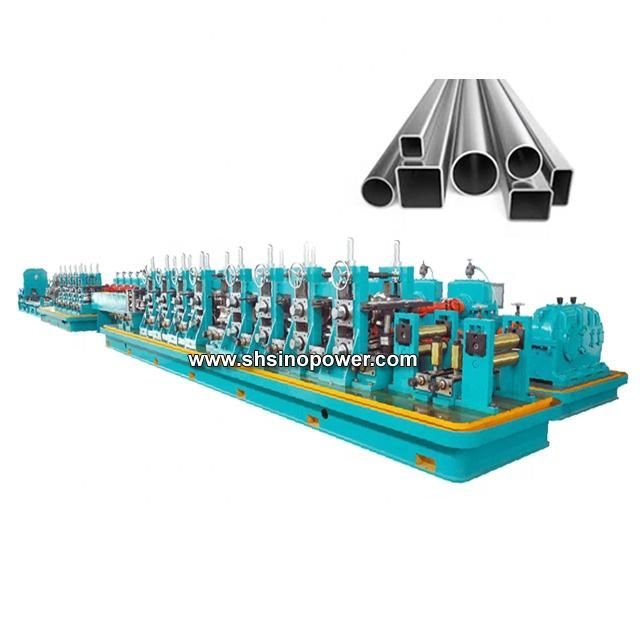

The high-frequency welded pipe machine is the main equipment of the welded steel pipe production line. It has functions such as uncoiling, tape feeding, roll forming and sizing, high-frequency fixed welding, cutting, and blanking. Below are the detailed specifications of our tube making production line.

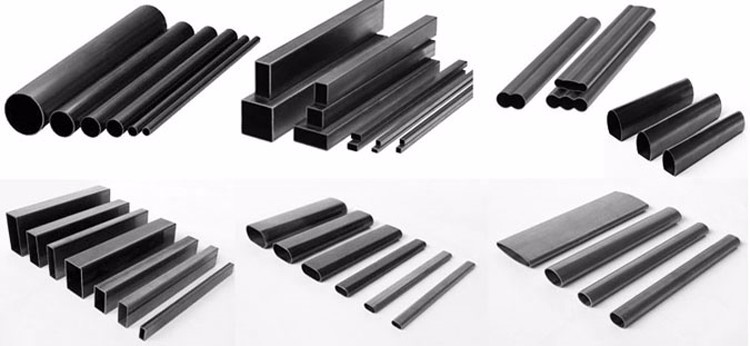

1: What kind of pipes can our pipe making factory produce?

1. Oil and gas pipelines 7. Wire and cable protective tubes

2. Heating pipe 8. Structural support steel pipe

3. Low pressure process pipeline 9. Industrial steel pipe

4. Low-pressure firefighting pipes 10. Decorative pipes

5. Sewer pipe 11. Water pipe

6. Steel scaffolding pipe 12. Construction pipe

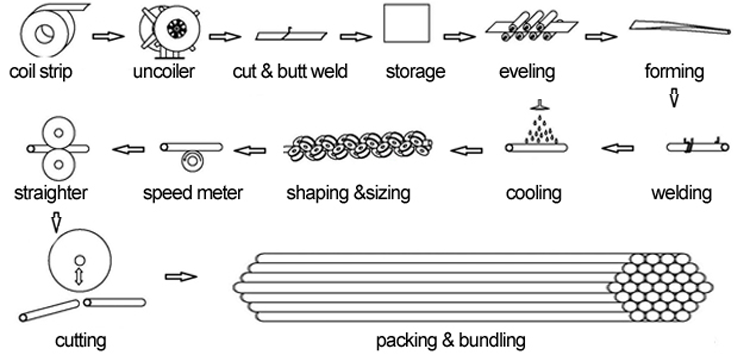

2. Our company’s tube mill flow chart

Standard flow chart of ISO/CE MS iron pipe making machine production line 8-219 mm ERW pipe making machine:

Step 1: Open the book

Function: The straight seam welded pipe production line supports the tension of the rolled plate and strip, and consists of a frame, a spindle, an increasing drum, and a brake.

There are three types: pneumatic, hydraulic and manual.

Step 2: Cut butt welding

2 types: automatic and manual

Function: Cut off the ends of each coil and then weld them together so that the pipe welding machine line can continue production.

Step 3: Strip the Accumulator

Function: Store strips to ensure continued production.

2 types: horizontal/vertical

Advantages: Horizontal type allows larger storage. Vertical ones are cheap and take up little space.

Step 4: Molding part.

Function: Form strip into tube

Advantage:

>Advanced molding technology

>One-step molding platform

>Reliable quality gearbox

>Siemens Bader Motor

Step 5: High frequency welding

Function: welding pipes of different thicknesses and diameters, high frequency welding machine welding machine power

Our advantage: We choose the best welding machine in China: SANY brand.

Step 6: Dimensions section

Function: Adjust tube size to exact size

Advantage:

>Advanced sizing technology

>One-step molding platform

>Reliable quality gearbox and Siemens Bader motor

>Pipe dimensional accuracy is high and error is small

Step 7: Flying Saw/Cold Saw

Function: Cut the pipe machine line pipe to the appropriate length.

Flying saw: easy to operate and low investment.

Cold sawing: no noise, no burrs, cutting accuracy and cross-section.

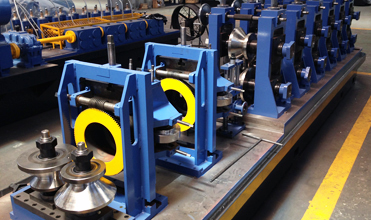

3. Detailed pictures of pipe making machine

With excellent product quality, CLP Group has successfully provided world-class products and services to more than 40 countries and regions around the world, such as: Poland, Spain, Russia, Yugoslavia, Ukraine, Turkey, Egypt, Saudi Arabia, India, Vietnam, Malaysia, Thailand, Philippines, Pakistan, Kazakhstan, Ethiopia, etc.

Below is ourStandard seriesOur pipe making machine,We also accept customization.

Model | round tube | Square and rectangular tubes | speed | ||||||

Diameter/mm | Thickness/mm | square. Dimensions/mm | Adjust size/mm | Thickness/mm | |||||

SP12 | 8-16 | 0.2-0.6 | 20-120m/minute | ||||||

SP16 | 8-25 | 0.2-1.0 | 7×7-20×20 | 7×7-25×15 | 0.2-0.8 | 20-120m/minute | |||

SP25 | 8-32 | 0.3-1.3 | 7×7-25×25 | 7×7-30×20 | 0.3-1.0 | 20-120m/minute | |||

SP28 | 8-42 | 0.3-1.8 | 7×7-30×30 | 7×7-40×20 | 0.3-1.3 | 20-120m/minute | |||

SP32 | 16-50.8 | 0.6-2.0 | 12×12-40×40 | 14×10-50×30 | 0.6-1.6 | 20-120m/minute | |||

SP45 | 19-63.5 | 0.6-2.5 | 15×15-50×50 | 20×10-70×30 | 0.6-2.0 | 20-120m/minute | |||

SP50 | 19-76 | 0.6-2.5 | 15×15-60×60 | 20×10-80×40 | 0.6-2.0 | 20-120m/minute | |||

SP60 | 19-76 | 0.6-3.0 | 15×15-60×60 | 20×10-80×40 | 0.6-2.5 | 20-100m/minute | |||

SP76 | 25-80 | 1.2-4.0 | 20×20-62×62 | 30×10-84×40 | 1.2-3.0 | 20-70m/minute | |||

SP90 | 32-90 | 1.5-4.5 | 25×25-70×70 | 30×20-90×50 | 1.5-3.5 | 20-60m/minute | |||

SP115 | 38-115 | 2.0-5.0 | 30×30-90×90 | 40×20-120×60 | 2.0-4.0 | 20-60m/minute | |||

SP165 | 60-165 | 2.0-6.0 | 45×45-130×130 | 60×30-150×100 | 2.0-4.5 | 15-50m/minute | |||

SP219 | 90-219 | 3.0-8.0 | 70×70-170×170 | 100×40-200×140 | 3.0×6.0 | 15-50m/minute | |||

Please click here to send me an inquiry

Return to home page

-

Fly cold saw gear box

-

China factory steel pipe factory stainless steel pipe making machine/pipe

-

HFH Street Lamp Pole Automatic Welding Production Line

-

Manufacturer Price ERW Tube Making Machine

-

High frequency welding stainless steel round tube welding machine tube mill equipment

-

Foshan YXH round square rectangle available stainless steel pipe rolling line steel pipe making machine iron pipe making machine

-

Metal Tube Mill / ERW Steel Tube Mill

-

High quality big discount high frequency welded steel pipe making machine for iron carbon galvanized steel pipe

-

Steel pipe/tube forming machine

-

Factory experienced metal flower decorative tube stamping machine

Other Products

-

$213750.00 / unit

$213750.00 / unit -

$135000.00 / unit

$135000.00 / unit -

Square pipe roll forming machine used Automatic steel ERW pipe mill line machine to make square tube$122000.00 / set

Square pipe roll forming machine used Automatic steel ERW pipe mill line machine to make square tube$122000.00 / set