Gypsum powder production from Wuxing

-

Supplier: Shijiazhuang Wuxing Machinery Co., Ltd. -

Region: Hebei, China -

Contact: Ms Aisha Zhao -

Price: $150000.00 /set -

Min. Order: 1 set

| Type: | Full-automatic; | After-sales Service Provided: | Engineers available to service machinery overseas; |

| Certification: | ISO+CE; | Features: | Automatic; |

| Raw material: | Natural Gypsum; | Condition: | New; |

| Warranty: | 1 Year; | Annual capacity: | 15000-300000 Tons; |

| Name: | Gypsum powder production from Wuxing; | Installation: | Engineers Guidance; |

| Power(W): | 380; | Supply Ability: | 5 Set/Sets per Year; |

| Application: | Gypsum Board; | Port: | Tianjin; |

| Brand Name: | Wuxing; | Place of Origin: | Hebei China (Mainland); |

| Technology: | Autoclave Boiling Furnace; | Dimension(L*W*H): | 64mX24mX8m; |

| Automatic Grade: | Automatic; | After-sales Service Provided: | Online support,Field installation, commissioning and training,Field maintenance and repair service,Video technical support; |

| Weight: | rely on production capacity; | Packaging Detail: | suit for container; |

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram,payple; | Voltage: | 220V 380V; |

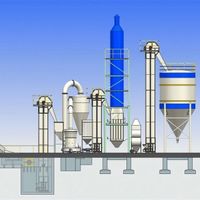

gypsum powder production line

gypsum powder is very important in today's lives.

Feeding and Crushing

Feed the gypsum rock to the raw material storage bin of the auto feeder by using loader. Then it will be transferred to the crusher to be crushed.

Milling

By using lifter,the gypsum will be transferred to silo and then transferred to Raymond mill by using electromagnetic feeder. Then use pulsed dust collector to eliminate the dust.

Calcining

Analytical engine will be used to control the fineness of gypsum powder.By using lifter,it will be transferred to fluidized calciner. The conductive oil which has been heated by the boiler will be the themal source. High pressure pressure blast which is from the roots blower will make sure that the gypsum powder insider the kiln is always boiling and heated evenly.

Loading

After heated,the gypsum powder will be transferred to the bin to be homogenized storage then transferred by tank car or packed and stored.

Gypsum plaster powder production line

Crusher breaks up large sized gypsum ore to small granule less 25mm. and then, separator mil the granule to powder with required fitness and deliver to boiling furnace to calcine. The calcined gypsum powder is delivered to grog bin for saving or production workshop for producing.

What’s our products advantage ?

(1) Working theory

the main part of boiling furnace is composed of thin and dense radiator pipes, which is filled with conduction oil to release the heat to the inside of the furnace.

Equipped at the bottom of the furnace, the roots blower makes the powder inside the furnace into the boiled state. The powder material backed and dehydrated with crystallization water at certain temperature, flow out through the outlet automatically.

The gypsum powder produced by this procedure has stable quality and well controlled crystallization water rate, initial and final set time. Further more, by using dry electrostatic cleaner, the equipment has over 95% dust collection efficiency and eliminate the dust pollution.

(2) Simple and sustainable structure

Because of the fluidization material, funace doesn't need rotatable component so that it easy to built and almost free of maintenance. thanks to the low temperature heat source, the furnace won't be damaged by over heating and has longer operating life.

(3) Compact design and less space requirement

With vertical arrangement, the dust catcher on the top of the furnace body is integrated with the boiling furnace compactly. The system not only less space but also avoids condensation of the dust catcher.

(4) Low energy consumption

The heat energy, passed form the heat source to the material, is almost all used for material's dehydration, except a small part is used to heat the cold air blew form the bottom of the heating furnace radiated form the furnace body. Since the boiling furnace uses twice heat source, the final heat efficiency should be boiler's heat efficiency ride stove's heat efficiency. the steam boilers or hot oil boilers are boilers, efficiency can reach 60-70% and the tot oil boiler's can reach 70-80%.(our company uses organic heat carrier hot oil boiler.) with steam, it can reach 57-67%,it can reach 67-76%.

(5)Good quality, ideal composition of Paris, stable physical

Property due to the low temperature heat source, the plaster does not tend to be over calcined. Only if controlling the discharte gypsum and with less than 5% anhydrite. And the spare is all hemihydrates gypsum. This composition is very ideal and with stable physical property.

This text looks a bit boring? Try clicking here to start communicating with me!!!

1.How about your price?

A:our price is not so high and aslo not so low.

One side we need gurantee the quiality of the machine , on the one side we need to give our customers a satificated price.

2.How much is your cost?

A:Do you have a well known about our product?If not,you can not judge fairly about our machines whether cheap or expensive.You care about price because you want have profit.Know more about our product and marketing strategies,or take a visit of our factory,you will know well about price.

3.Why your price is cheap?

A:That is our selling points and product strategies.First,we buy a large number of material,and reduce the cost.Second,we have good faith management,no bad assests,the mnagement can be maximized efficiency.And last,Our management idea is a cost-effective way,low profits,low price.If you have sincere buying our machine,we can discuss price.

4.Do you have quality assurance?

A:Definitely,we have.If we can not assure the quality,can I sell to you?I seek to a long business cooperation,not only once.

We have passed ISO9001.

5.What should do if happens quality problem?

A:No one wants problems.The reason caused by delivery,we will analyse at once,if our problems,we take responsibility,pls don’t worry,we will follow by the contract,solve problems immediately and provide good service to you.

Suitable package for long distance transportation

wooden boxes: load electrical cabinet, small parts etc.

carton boxes: load motor, screw, bolt etc.

plastic package: rock wool.

-

The best-selling advanced pure calcined gypsum powder production line

-

Clirik Gypsum Vertical Mill is a high-quality grinding equipment.

-

Complete gypsum production line with calcining plant in gypsum manufacturing plant

-

Gypsum board machine German gypsum board production line adopts Knauf technology

-

Latest Technology Gypsum Calcination Best Performance Construction Gypsum Making Machine Gypsum Powder Production Machinery Factory

-

Gypsum board production line

-

On-site installation of gypsum powder production line manufacturers equipped with gypsum powder mills

-

2022 Precipitated Calcium Carbonate Gypsum Processing Plant 2.7-40t/h Gypsum Powder Production Machine Gypsum Powder Production

-

Large capacity and low investment cost gypsum powder production plant/gypsum powder production line for sale

-

2022 Ex-factory Price Gypsum Powder Making Machine/Fully Automatic High Yield Gypsum Powder Production Line