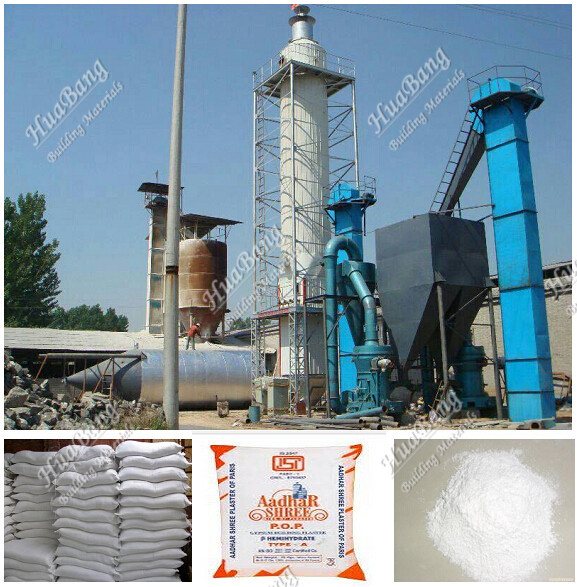

The best-selling advanced pure calcined gypsum powder production line

-

Supplier: Linyi City Mengshan Tourism District Huabang Building Materials Co., Ltd. -

Region: Shandong, China -

Contact: Mr zhao David -

Price: $201000.00 /set -

Min. Order: 1 set

| Dimensions (length*width*height): | 45mx30m | Automatic level: | automatic |

| Voltage: | 220V | payment terms: | Letter of credit, wire transfer |

| Post-warranty service: | Video technical support, online support, spare parts, on-site maintenance and repair services | Place of origin: | Shandong Province, China |

| heating method: | hot oil and hot air | strength: | Production capacity by year |

| Heating fuel: | Natural gas, coal, diesel, heavy oil, light oil, etc. | raw material: | gypsum mine |

| Showroom location: | Indonesia, Pakistan, India, Sri Lanka, Bangladesh, Uzbekistan | Certification: | We can do it according to your requirement |

| Applicable industries: | Building materials stores, machine repair shops, manufacturing plants, construction engineering, energy and mining | Annual production capacity: | 15,000 to 500,000 tons |

| feature: | customized product | type: | Gypsum powder making machine |

| Packaging details: | Best-selling advanced pure calcined gypsum powder production line: packaging suitable for long-distance transportation. | brand: | Winbond |

| application: | Produce gypsum powder | weight: | 170000kg |

| After-sales service provided: | Online support, free spare parts, on-site installation, commissioning and training, on-site maintenance and repair services, video technical support, engineers available to repair machinery overseas | Industry experience: | There are 16 years left until 2015 |

| Local service locations: | Egypt, Türkiye, Indonesia, Pakistan | Supply capacity: | Annual output of 20 sets of gypsum powder production lines |

| Export experience: | There are still 12 years until 2015 | Main selling points: | Easy to operate |

| Warranty: | 1 year | Health status: | new |

| port: | Port of Qingdao, China | we are: | Gypsum powder making machine |

| net: | 170 mesh |

The best-selling advanced pure calcined gypsum powder production line

Product Description

product name | Gypsum/gypsum powder production line/making machine |

annual production capacity | 15,000 to 500,000 tons |

type | Natural gypsum and desulfurized gypsum |

net | 170 mesh |

heating method | hot oil and hot air |

raw material | gypsum mine |

degree of automation | Fully automatic and semi-automatic |

final product specifications | Gypsum powder |

boiler fuel | Natural gas, coal, diesel, heavy oil, light oil, etc. |

examine | SGS Inspection and Quarantine Bureau |

Export experience | There are still 12 years until 2015 |

Industry experience | There are 16 years left until 2015 |

detailed image

Raw material crushing system_

The crusher breaks large-sized gypsum ore into small ore with a diameter of 25mm

Mill system

- High efficiency grinder

- Equipment reliability and availability are significantly improved

- Make gypsum powder processing more stable and pure

Calciner system

- Simple structure and not easily damaged

- Space saving, equipment intensive

- Low energy costs

- Excellent quality, ideal hemihydrate content, and stable physical properties.

Finished product transportation and storage

- Bucket elevator

- Finished product warehouse

- Silo wall vibrator

- One way spiral gate

- Steel Impeller Feeder

- Packing Machine

dust collection system

- The dust production of the high-voltage electrostatic precipitator meets local environmental requirements.

Heating system

- Fuel: natural gas, coal, diesel, heavy oil, light oil, etc.

Electronic control system_

- Using advanced DCS and SIMENS PLC, the equipment is separated but controlled centrally

- Improve scheduling decision-making efficiency

- Greatly improve the level of production management.

manufactures

Application of final product gypsum powder

- Used in the production of gypsum boards

- plaster

Production Process

Advantages of machiningGypsum powder production line:

- All raw materials and post-processing are certified by suppliers and must pass incoming inspection before production;

- The products are processed with precision and the assembly accuracy is high.

Packaging and shipping

Load photos abovefor your information:

1. | All electrical components are shipped in wooden boxes, and the rest are shipped naked or in bulk. |

2. | All cargo will be loaded at 40HQ, or in frame or bulk carriers if the boiler is overweight or oversized. |

3. | All packaging is suitable for long distance shipping. |

4. | If you have any requirements for packaging, we will do it as required. |

company information

gypsum plaster

production line

-

Clirik Gypsum Vertical Mill is a high-quality grinding equipment.

-

Complete gypsum production line with calcining plant in gypsum manufacturing plant

-

Gypsum board machine German gypsum board production line adopts Knauf technology

-

Latest Technology Gypsum Calcination Best Performance Construction Gypsum Making Machine Gypsum Powder Production Machinery Factory

-

Gypsum board production line

-

On-site installation of gypsum powder production line manufacturers equipped with gypsum powder mills

-

2022 Precipitated Calcium Carbonate Gypsum Processing Plant 2.7-40t/h Gypsum Powder Production Machine Gypsum Powder Production

-

Large capacity and low investment cost gypsum powder production plant/gypsum powder production line for sale

-

2022 Ex-factory Price Gypsum Powder Making Machine/Fully Automatic High Yield Gypsum Powder Production Line

-

Automatic gypsum powder production line, gypsum powder factory

Other Products

-

$246000.00 / set

$246000.00 / set -

$175600.00 / set

$175600.00 / set