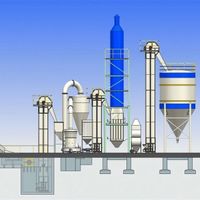

Automatic gypsum powder production line, gypsum powder factory

-

Supplier: Zhengzhou Mega Industry Co., Ltd. -

Region: Henan, China -

Contact: Ms IVY HAN -

Price: $88888.00 /set -

Min. Order: 1 set

| Supply capacity: | 100 sets per month | Auto grade: | automatic |

| Certification: | ISO9001:2000 | strength: | ~ |

| brand: | Mega | Packaging Details: | Bulk Packaging |

| After Warranty Service: | Online support, spare parts, on-site maintenance and repair services | Main selling point: | easy to operate |

| Showroom location: | not any | After-sales service provided: | Online support, on-site installation and commissioning training, on-site maintenance and repair services |

| weight: | ~ | payment terms: | L/C,T/T,Western Union |

| Applicable industries: | Building Materials Store, Construction Engineering, Energy & Mining | application: | construction |

| port: | Qingdao, Tianjin, Shanghai | Dimensions (L*W*H): | ~ |

| Local service location: | not any | Health status: | new |

| Warranty: | 1 year | Voltage: | 10KV, 8KV |

| place of origin; place of origin: | Henan, China |

Gypsum powder production lineAdopt advanced equipment such as boiling furnace, high-voltage electrostatic dust removal, energy saving and environmental protection.

Description of building gypsum powder production line |

capacity: 30,000 tons/year~300,000 tons/year Automation: Fully automatic Calcining system: It is calcined in a boiling furnace, and a heat-conducting oil furnace is used as the heat source. Fuel: Coal, Natural Gas, Heavy Oil, Diesel Main materials: natural gypsum rock, desulfurized gypsum, dephosphorized gypsum Product quality standards: Comply with the national standard "GB/T 9776-2008 Plaster of Construction" |

Natural gypsum generally includes dehydrated gypsum and anhydrite. In order to obtain valuable materials, we generally obtain hemihydrate gypsum by heating dehydrated gypsum.

Main technology of gypsum powder production line

Gypsum ore -> first breaking -> second breaking -> grinding -> calcining -> aging -> finished product (CaSO4.1/2H2O)

Raw materials for gypsum powder production line

Gypsum ore CaSO4.2H2O content 80%

Mine grade and crystal form affect the quality of hemihydrate gypsum

-

The best-selling advanced pure calcined gypsum powder production line

-

Clirik Gypsum Vertical Mill is a high-quality grinding equipment.

-

Complete gypsum production line with calcining plant in gypsum manufacturing plant

-

Gypsum board machine German gypsum board production line adopts Knauf technology

-

Latest Technology Gypsum Calcination Best Performance Construction Gypsum Making Machine Gypsum Powder Production Machinery Factory

-

Gypsum board production line

-

On-site installation of gypsum powder production line manufacturers equipped with gypsum powder mills

-

2022 Precipitated Calcium Carbonate Gypsum Processing Plant 2.7-40t/h Gypsum Powder Production Machine Gypsum Powder Production

-

Large capacity and low investment cost gypsum powder production plant/gypsum powder production line for sale

-

2022 Ex-factory Price Gypsum Powder Making Machine/Fully Automatic High Yield Gypsum Powder Production Line