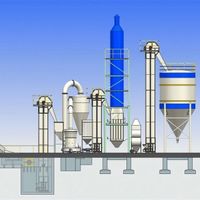

On-site installation of gypsum powder production line manufacturers equipped with gypsum powder mills

-

Supplier: Shijiazhuang Jiurui Machinery Co., Ltd. -

Region: Hebei, China -

Contact: Ms Willa Wang -

Price: $325000.00 / 1 - 1 sets

$310000.00 / >=2 sets -

Min. Order: 1 set

| Automatic level: | automatic | Working Standards: | Drying principle of high temperature calciner |

| Mechanical test report: | if | Supply capacity: | 40 sets per year |

| port: | Xingang< Tianjin | Core components: | PLC, engine, bearing, gearbox, motor, pressure vessel, gear, pump |

| Showroom location: | not any | Voltage: | local requirements |

| Applicable industries: | manufacturing plant | Health status: | new, new |

| brand: | Jiu Rui | Core component warranty: | 1 year |

| fuel: | Natural Gas Coal Electricity | After warranty service: | Video Technical Support |

| Packaging Details: | Packaging and Shipping 1 Sales Unit Single 2 Single Package Size: 30X20X15 cm 3 Single Gross Weight: 30000.0 kg 4 Package Type: Wooden Box If you have any requirements for packaging, we will do so. | feature: | save time |

| Marketing Type: | normal product | strength: | 800-1200 kW |

| weight: | 17T, 5000kg | payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram |

| Power (watts): | 800-1200kw | brand: | Jiu Rui |

| Origin: | Hebei, China (Mainland), Hebei, China | Video shipment inspection: | if |

| Production capacity: | 3 million-10 million square meters per year | Dimensions (L*W*H): | Factory demand |

| application: | make gypsum powder | Warranty: | 1 year |

| Main selling points: | easy to operate |

On-site installation of gypsum powder production line manufacturers equipped with gypsum powder mills

| product name | China Supplier Best Price Gypsum Powder Production Manufacturing Machine |

| CaSO4•2H2O content | 90~95% |

| Na2O content | ≤0.02% |

| K2O content | ≤0.02% |

| Chlorine content | ≤10ppm |

| free water content | ≤3% |

| lump size | ≤350mm |

other information

|

Gypsum powder production line

|

|||

|

Gypsum board production line

|

|||

|

Gypsum board lamination production line

|

|||

Applications

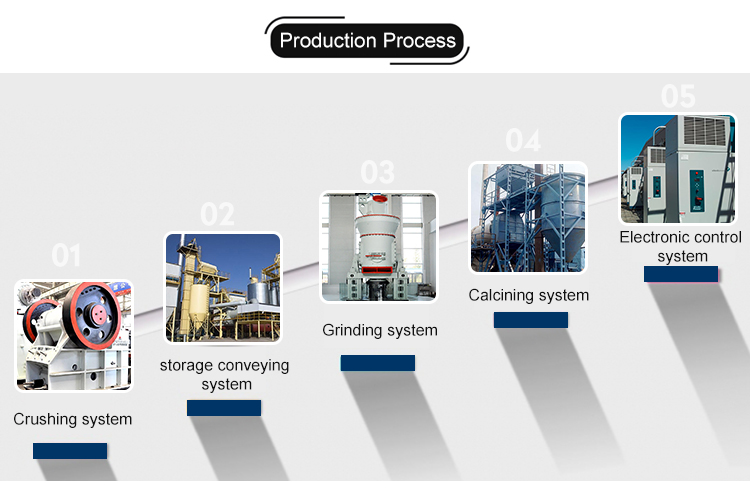

Gypsum powder machine manufacturers develop, manufacture, install and debug gypsum powder production lines. The main process includes crushing system, grinding system, calcination system, energy supply system, packaging system, etc.

Production line capacity ranges from 30,000 tons/year to 600,000 tons/year.

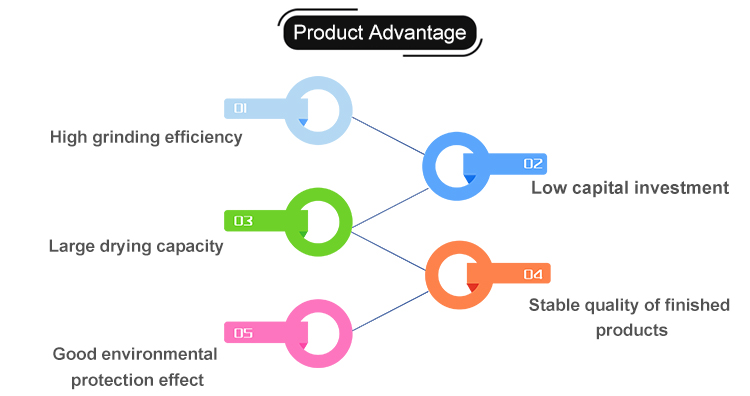

The production line has the advantages of low energy consumption, high degree of automation, small installation space and convenient operation. They were developed by gypsum powder machine manufacturers.

With the development of the gypsum industry, the demand for both the quantity and quality of gypsum powder is increasing rapidly. At the same time, the production progress of gypsum powder was gradually accelerated. In the production process of gypsum powder, drying and dehydration are the key link and the most difficult link to control. In order to solve this problem, the fluidized calciner is a new type of drying and dehydrating equipment, which is developed on the basis of exploring the field of gypsum production. The following is a brief introduction to the gypsum production process and working principle of the fluidized calciner.

application

-

The best-selling advanced pure calcined gypsum powder production line

-

Clirik Gypsum Vertical Mill is a high-quality grinding equipment.

-

Complete gypsum production line with calcining plant in gypsum manufacturing plant

-

Gypsum board machine German gypsum board production line adopts Knauf technology

-

Latest Technology Gypsum Calcination Best Performance Construction Gypsum Making Machine Gypsum Powder Production Machinery Factory

-

Gypsum board production line

-

2022 Precipitated Calcium Carbonate Gypsum Processing Plant 2.7-40t/h Gypsum Powder Production Machine Gypsum Powder Production

-

Large capacity and low investment cost gypsum powder production plant/gypsum powder production line for sale

-

2022 Ex-factory Price Gypsum Powder Making Machine/Fully Automatic High Yield Gypsum Powder Production Line

-

Automatic gypsum powder production line, gypsum powder factory

Other Products

-

$200000.00 / set

$200000.00 / set