Clirik Gypsum Vertical Mill is a high-quality grinding equipment.

-

Supplier: Shanghai Clirik Machinery Co., Ltd. -

Region: Shanghai, China -

Contact: Ms Clirik Lee -

Price: $85000.00 / 1 - 4 sets

$68000.00 / 5 - 9 sets

$58000.00 / >=10 sets -

Min. Order: 1 set

Product details

| Core component warranty: | 1 year | payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram, transferable |

| Core components: | PLC, engine, motor | Output size: | 150-2500 mesh |

| feature: | free regulation | Showroom location: | not any |

| Machine classification: | Micron milling machine | Health status: | new |

| Enter dimensions (mm): | ≤20mm | Package preview: | |

| Place of origin: | Shanghai | Dimensions (length*width*height): | Five models |

| Marketing type: | normal product | Automatic level: | automatic |

| product name: | HGM grinding machine | Main selling points: | Easy to operate |

| Warranty: | 1 year | Video outbound inspection: | if |

| After-sales service: | Provide grinding machine technical support | quality: | high level |

| strength: | 123-450kW | Online service hours: | within 24 hours |

| Supply capacity: | 20 groups per week | Applicable industries: | manufacturing plant |

| color: | client needs | Packaging details: | wooden box |

| Mechanical test report: | if | price: | Negotiable and reasonable |

| application: | Stone powder grinding and mineral powder processing | Voltage: | 220V |

| weight: | 4263kg | port: | Shanghai |

| brand: | Clearik |

product description

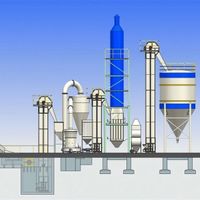

Gypsum powder production equipment

Gypsum powder production equipmentIt is a new type of activated carbon grinding machine developed by our companyClearikRelying on its own technology research and development capabilities, it draws on the advantages of similar products at home and abroad.With rolling, grinding, impactAnd other comprehensive mechanical crushing properties such as comprehensive mechanical crushing properties.

of this seriesGypsum powder production equipmentHas the following characteristicsLarge output, low energy consumption, long service life and easy maintenance. This is a perfect choice for clients who prefer a high return on investment.

thisGypsum powdergrinderCan grind non-metallic ore materials. For example plaster,Calcite, Chalk and Limestone, dolomite, bentonite, talc, mica, magnesia, illite, pyrophyllite, vermiculite, sepiolite, attapulgite, gray spot, barite, alunite, black lead, fluorite, phosphate, potassium fertilizer, pumice,More than 1,000 Mohs hardness levels and below 6 It is not a flammable or explosive brittle substance.

- -Five models:HGM80, HGM90, HGM100, HGM125 and HGM1680L

- -Finished powder fineness:325 mesh~3000 mesh, 5-74 micron

- -Capacity (tons/hour):0.4 tons/hour-30 tons/hour

product specifications

Product parametersGypsum powderProduction equipment:

Model | HGM80 | HGM90L | HGM100L-II HGM100P | HGM125L | HGM168L | |||||

ring diameter (mm) | 800 | 900 | 1000 | 1250 | 1680 | |||||

ring number (pieces) | 3 | 3 | 4 | 4 | 4 | |||||

Number of rollers (pieces) | 18-21st | 24-29th | 28-36 | 30-40 | 30-44 | |||||

Spindle speed (rev minutes) | 230-240 | 200-220 | 180-200 | 135-155 | 120-130 | |||||

Enter dimensions (mm) | ≤20 | ≤20 | ≤20 | ≤20 | ≤20 | |||||

product size (eh/m) | 74-5 (200-2500) | 74-5 (200-2500) | 74-5 (200-2500) | 100-8 (150-2000) | 100-9 (150-1500) | |||||

capacity (tons/hour) | 0.5-5.5 | 0.8-6.5 | 1.2-10 1.2-11 | 2.5-20 | 5-45 | |||||

Outlet size length*width*height (rice) | 15.1*4.2*7.3 | 18.4*3.9*7.8 | 22.7*3.6*8.5 | 27.3*4.2*9.9 | 31.7*7.7*12.6 | |||||

notes:Production capacity is subject to feedback from domestic calcium carbonate powder factories. Note: Production capacity is subject to feedback from domestic calcium carbonate powder factories. | ||||||||||

Work principles

working principle Gypsum powder production equipment, ultra-fine activated carbon powder mill, vertical powder ultra-fine mill, vertical powder mill, powder making machine:

Gypsum powder grinding machine It is mainly composed of main machine, classifier, powder collector, dust collector, blower, muffler, soundproof room, crusher, bucket elevator, storage hopper, vibrating feeder, etc.

Gypsum powder grinding machine It is mainly composed of main machine, classifier, powder collector, dust collector, blower, muffler, soundproof room, crusher, bucket elevator, storage hopper, vibrating feeder, etc.

You can learn howGypsum powderProduction equipment Work by watching videos.

Function overview

Gypsum powderProduction equipmentfeature:

1. Meet customers’ requirements for powders with different finenesses. The fineness of the finished powder is adjustable and the quality is stable. 2. Built-in high-efficiency classifier, higher classification accuracy and better classification effect. 3. Adopting a newly upgraded host transmission mechanism, it has higher output, lower energy consumption and easy maintenance. 4. The main wearing parts are made of high-quality wear-resistant alloy steel, which has a longer service life. 5. The entire system works under negative pressure, no dust emissions, no coarse particle air pollution, more environmentally friendly, and higher powder fineness recovery rate. 6. Intelligent PLC control, remote centralized control, easy operation with one button, and intelligent control of feeding ensure stable operation of the mill and high output. 7. The entire grinding mill system has a compact structure, which can save factory space and has low infrastructure construction costs. It is a cost-effective investment. High quality calcium carbonate grinding mill for calcium carbonate powder production line

If you want to know more about our products, you can leave us a message.

Customer case

The picture below isGypsum powderProduction equipmentWebsites of our previous clients.

If you want to know more you canClick hereContact our customer service staff.

If you want to know more you canClick hereContact our customer service staff.

Other products offered

alsoHGM seriesGypsum powderProduction equipment We also have other activated carbon powdersUltrafine grinding machinefor you to choose.

VIEW MORE

You may like

-

The best-selling advanced pure calcined gypsum powder production line

-

Complete gypsum production line with calcining plant in gypsum manufacturing plant

-

Gypsum board machine German gypsum board production line adopts Knauf technology

-

Latest Technology Gypsum Calcination Best Performance Construction Gypsum Making Machine Gypsum Powder Production Machinery Factory

-

Gypsum board production line

-

On-site installation of gypsum powder production line manufacturers equipped with gypsum powder mills

-

2022 Precipitated Calcium Carbonate Gypsum Processing Plant 2.7-40t/h Gypsum Powder Production Machine Gypsum Powder Production

-

Large capacity and low investment cost gypsum powder production plant/gypsum powder production line for sale

-

2022 Ex-factory Price Gypsum Powder Making Machine/Fully Automatic High Yield Gypsum Powder Production Line

-

Automatic gypsum powder production line, gypsum powder factory

Related Search

high quality grinding discs metal

high quality pdh equipment

automatic gypsum powder equipment with high quality

high quality auto parts

high quality industrial dehumidifiers

high quality baby wet wipes

elephant chain hoist with high quality

pallet packing pp strapping high quality

high quality cooling tower types

high quality inkjet printer cartridge