Complete gypsum production line with calcining plant in gypsum manufacturing plant

-

Supplier: Henan Fantianliang Machinery& Equipment Co., Ltd. -

Region: Henan, China -

Contact: Ms Discount Cheap -

Price: $600.00 /set -

Min. Order: 1 set

| Showroom location: | Peru, Russia, Kazakhstan, Kyrgyzstan, Uzbekistan, Tajikistan, Malaysia | Place of origin: | Henan, China |

| Core component warranty: | 2 years | Packaging details: | Gypsum powder production line, gypsum grinding machine, gypsum powder making machine are packed in 40HQ container |

| Warranty: | 2 years | Video outbound inspection: | if |

| Certificate: | ISO9001:2000 | port: | Qingdao, Shanghai, Tianjin |

| Supply capacity: | 10 sets per month | feature: | high working efficiency |

| Health status: | new | Finished goods: | Gypsum powder fineness |

| product name: | Gypsum grinding equipment | Install: | Under the guidance of engineers |

| payment terms: | L/C, Western Union, D/P, D/A, T/T | application: | Complete gypsum powder production line |

| strength: | model-based | Voltage: | 220V, 380V or other customer required voltage |

| weight: | 8000kg | Marketing type: | normal product |

| Package preview: | Automatic level: | automatic | |

| Key words: | Gypsum powder production line | brand: | faster than light |

| capacity: | 0.8-18 tons/hour | Main selling points: | long lasting |

| Mechanical test report: | if | Core components: | PLC, gearbox, pressure vessel |

| Applicable industries: | Manufacturing plants, energy and mining |

Complete gypsum production line with calcining plant in gypsum manufacturing plant

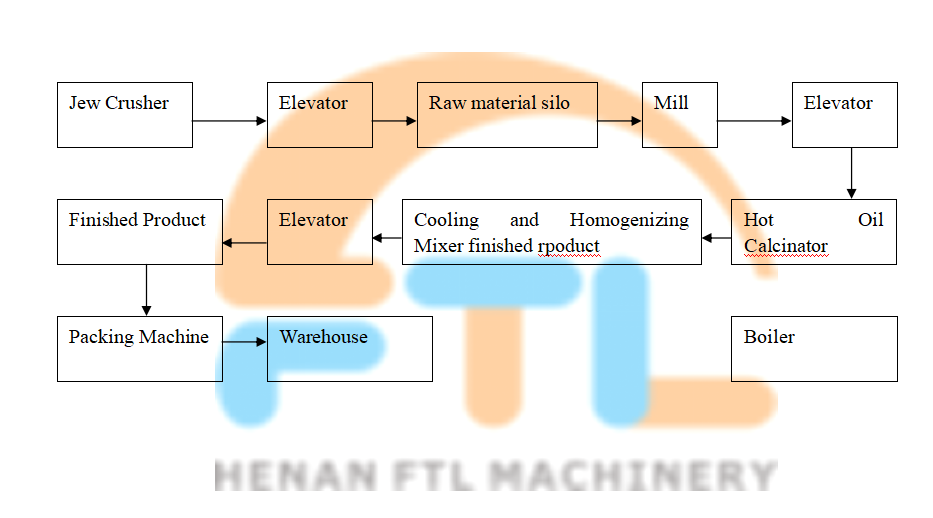

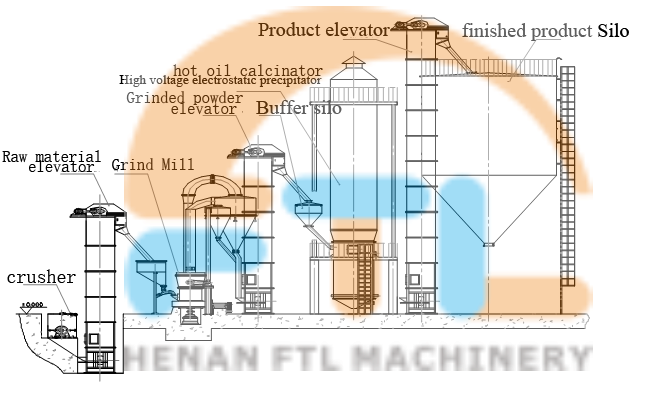

With the development and progress of the gypsum industry, the demand for gypsum powder continues to increase. At the same time, the production process of gypsum powder is also improving day by day. The key process in the production of gypsum powder is dehydration, which is also the most difficult link. In response to this situation, we have designed a new type of dehydration equipment that meets the requirements of various gypsum powder products - a gypsum powder production and calcining production line (hot oil calcining furnace).

The factory's production uses a variety of processes. First, the gypsum ore is crushed, transported and stored in the raw material bin, and then the crushed gypsum ore is ground into powder of required fineness by Raymond grinding, and then the gypsum powder is transported to the calcining section through a metering feeding device to obtain the calcined , the calcined gypsum is modified by the pulverizer and cooled by the cooling device. Finally, the finished gypsum is transported and stored.

Natural gypsum powder production process flow:

Preliminary crushing of gypsum ore: jaw crusher or hammer crusher is usually used for crushing

Grinding of gypsum ore: The initially crushed gypsum ore is sent to the mill for further fine grinding to obtain gypsum powder of the required fineness.

Calcining of gypsum ore: The finely ground gypsum ore is sent to the decomposition furnace for high-temperature calcination. During the calcination process, the crystal water in the gypsum ore is released to form gypsum clinker.

Gypsum clinker cooling: The calcined gypsum clinker is quickly cooled through the cooling device to avoid secondary calcination.

Gypsum powder undergoes strict quality testing and quality control, and qualified gypsum powder will be packaged or put into use for different construction and industrial applications.

Material consumption parameters

|

tons/year |

tons/hour |

Ore consumption (tons/year) |

|

20000 |

2.78 |

24000 |

|

30000 |

4.12 |

36000 |

|

40000 |

5.56 |

48000 |

|

60000 |

8.24 |

72000 |

|

80000 |

11.11 |

96000 |

|

100000 |

13.88 |

120000 |

|

150000 |

20.83 |

180000 |

|

200000 |

27.78 |

240000 |

|

300000 |

41.66 |

360,000 |

Gypsum product parameters

1. Fineness: ≥100 mesh;

2. Bending strength (directly related to raw materials): ≥1.8Mpa; Compressive strength: ≥3.0Mpa;

3. Main ingredients: semi-hydrated matter: ≥80% (adjustable); gypsum <5% (adjustable); soluble anhydrous matter <5% (adjustable).

4. Initial setting time: 3-8min (adjustable); Final setting time: 6~15min (adjustable)

5.Concentration: 65%~75% (adjustable)

Features of our natural gypsum plant

1. Equipped with a feeding stabilization system to achieve stable feeding, stable feeding and heating of the fluidized bed combustion boiler. The feeding stabilization system consists of a feeding stabilizing bin and a conveying device (measuring screw or belt scale).

2. The calcining system adopts the hot air boiling furnace calcining process to evenly calcine the gypsum raw materials.

3. Add a cooling device to cool the gypsum before entering the silo to prevent the gypsum from deteriorating due to excessive temperature.

4. Silo turnover system: The quality of materials in different periods is different, so the quality of the products made is different. The silo turning system can evenly mix new and old materials so that the products have the same quality. In addition, the system prevents overheating deterioration caused by heat generated by powder accumulation.

5. The dust removal system uses a bag dust collector to ensure that the dust generated during pre-drying, transportation, grinding, calcination, and aging is purified and then discharged to meet the requirements of the working environment.

6. Use a distributed control system to centrally control distributed equipment.

-

The best-selling advanced pure calcined gypsum powder production line

-

Clirik Gypsum Vertical Mill is a high-quality grinding equipment.

-

Gypsum board machine German gypsum board production line adopts Knauf technology

-

Latest Technology Gypsum Calcination Best Performance Construction Gypsum Making Machine Gypsum Powder Production Machinery Factory

-

Gypsum board production line

-

On-site installation of gypsum powder production line manufacturers equipped with gypsum powder mills

-

2022 Precipitated Calcium Carbonate Gypsum Processing Plant 2.7-40t/h Gypsum Powder Production Machine Gypsum Powder Production

-

Large capacity and low investment cost gypsum powder production plant/gypsum powder production line for sale

-

2022 Ex-factory Price Gypsum Powder Making Machine/Fully Automatic High Yield Gypsum Powder Production Line

-

Automatic gypsum powder production line, gypsum powder factory