VSI Series Sand Making Machine/Ore Sand Limestone Crushing Plant With Factory Price

-

Supplier: The Nile Machinery Co., Ltd. -

Region: Henan, China -

Contact: Ms Lily Li -

Price: $50000.00 /set -

Min. Order: 1 set

| Port: | Qingdao Port; | Voltage: | 380V; |

| Condition: | New; | Double motor power(kw): | 2*55; |

| Payment Terms: | L/C,T/T; | Warranty of core components: | 1 Year; |

| Video outgoing-inspection: | Provided; | Rotate speed(r/min): | 1700-1890; |

| Marketing Type: | New Product 2020; | Packaging Detail: | Standard package in wooden boxes or container.; |

| Model of motor: | Y250M-4; | Machinery Test Report: | Provided; |

| Brand Name: | The Nile CO.,LTD; | After Warranty Service: | Online support; |

| Supply Ability: | 300 Set/Sets per Month; | Local Service Location: | Kenya; |

| Power: | 2*55KW; | Place of Origin: | Henan China; |

| Showroom Location: | Kenya; | Factory visit: | Welcome; |

| Applicable Industries: | Building Material Shops,Construction works ,Energy & Mining; | After-sales Service Provided: | Online support,Video technical support; |

| Key Selling Points: | Easy to Operate; | Certification: | ISO CE; |

| Capacity(T/H): | 60-180; | Dimension(L*W*H): | 3600*2248*2533mm; |

| Warranty: | 1 Year; | Core Components: | Motor; |

| Weight: | 10T; | Max. feeding size(mm): | 35; |

VSI Series Sand Making Machine/Ore Sand Limestone Crushing Plant With Factory Price

VSI Sand Making Machine is also called a vertical sand making machine.It can process all kinds of rock,gravel and river pebbles to be used in construction and with various grain sizes.The sand has uniformity of plasmid and high compressive strength.It is far more in line with the construction requirements than the sand produced by natural sand and ordinary hammer sanding machine and can improve the building quality.

The VSI sand making machine is the necessary equipment for the mechanism sand.It adopts the principle and technology of the"stone hitting stone" crusher,which makes the finished product with excellent grain shape,reasonable gradation and improved production efficiency,especially suitable for artificial sand making and stone shaping.

It can supply high quality sand aggregate for high building,expressway(railway) construction,municipal engineering,large scale irrigation establishment,concrete batching plant and many other areas.

VSI Sand making machine Working Principle:

1.Central feeding:Raw materials fall down into the feeding hopper of the VSI sand making machine,then enters the impeller through central entrance inlet,thus the material being accelerated by the high-speed impeller and being thrown out at the speed of 60-75m/s.It is crushed when hitting the impact plate,and the end products comes out from the discharging outlet.

2.Ring feeding:Raw materials fall down into the feeding hopper,and the materials are divided into two parts by a special plate.Some materials enter the sand making machine’s impeller through the center of the plate and the other part of materials falls down from outside of the plate.The materials thrown out earlier crush the materials down from outside,thus the materials crushed and re-crushed.

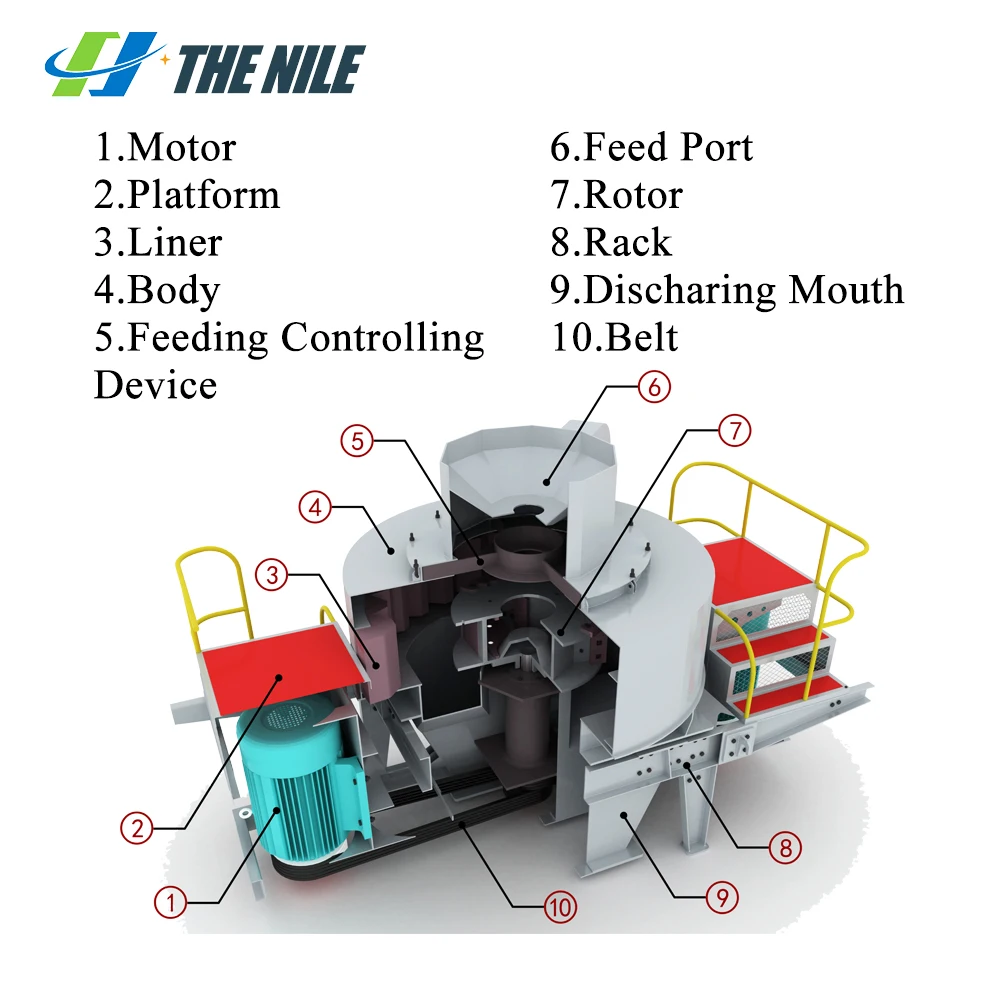

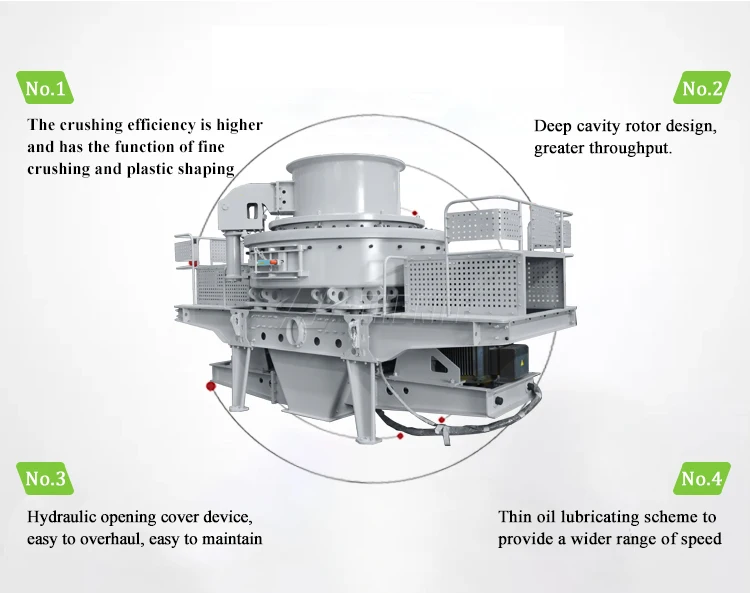

Sand Making Machine Features

1.The sand making machine has a simple structure,unique bearing and advanced spindle design,which makes the sand making machine have the characteristics of heavy load and high speed rotation;

2.The sand making machine has a good shaping function for the ore, and the finished material has a more uniform particle size;

3.With fine crushing, rough grinding function,high efficiency and energy saving,high wear resistance,long service life of wearing parts;

4.During the production process,the stone material can form a protective bottom layer,and the body is wear-free and durable.

| Model No. | VSI7611 | VSI8518 | VSI9526 | VSI1140 | VSI1145 | |

|

Capacity (t/h) |

Cascade Feeding | 120-180 | 200-260 | 300-380 | 450-520 | 500-640 |

| Full Central Feeding | 60-90 | 100-130 | 150-190 | 225-260 | 250-360 | |

| Max. Feeding size(mm) | Soft Material | 35 | 40 | 45 | 50 | 50 |

| Hard Material | 30 | 35 | 40 | 45 | 45 | |

| Rotation Speed (r/min) | 1700-1890 | 1520-1690 | 1360-1510 | 1180-1310 | 1100-1310 | |

| Model of Motor | Y250M-4 | Y280M-4 | Y315M-4 | Y315L2-4 | Y315L2-4 | |

| Double Motor Power | 55*2 | 90*2 | 132*2 | 200*2 | 220*2 | |

| Weight (t) | 10 | 12 | 16 | 25.6 | 27.5 | |

*All the sand making machine are packed by crate wood,other parts are a nude package,or as client demand;

*If the sand making machine size is suitable for container ship,usually by container;

*If the sand making machine size is too big, usually by bulk ship or by container after truncation;

*Transport ways are based on reducing the cost for you and keep the crane performance.

The Nile Co.,Ltd.is committed to designing,producing grinding mills,crushers,conveyors,feeding machines,drying and calcinating as well as beneficiation equipment,fine sand recycling equipment etc,which are widely applied in electricity,metallurgy,mine and quarry, wharf,granary,chemical industry.Our products have been spread all over China,and also exported to European,American,Asian,African countries and enjoyed great popularity among our customers.

Our company owns an experienced and skilled sales and service team which compose a perfect service network.We will send the professional engineers to the installation sites and provide guidance for the installation,commissioning and initial run as well as planning administration of the equipments after purchase.

We can not only provide good quality sand making machine, but also provide the best service for our clients. The series of professional technology services will make you have an excellent product experience.

Pre-sale services:

(1) The advice of model choice.

(2) Design and manufacture machines according to customer's special requirements

(3) The company is free of charge to the user on-site engineering and technical personnel planning site for the user to design the best processes and program

After-sale services :

(1) Arrange technicians to go to the site to guide installation

(2) If your machine is out of warranty period, you can go to the Nile's overseas office to buy spare parts.

(4) complete sets of equipment installed, 1-2 full-time technical staff to stay free of charge to help customers on-site production of 1 month, until the user' satisfaction.

Q1: Are you factory or trade company?

A1: We are factory.

Q2: Where your products have been exported before?

A2: Our products have been sold to South Asia, Africa, South America, middle East and so on.

Q3: How will you help the customer to install the equipment?

A3: Our senior engineer will guide the installation and commissioning as well as the initial production at

Q4: How about the wear parts supply?

A4: We offer wear parts to our customer with our most favorable price. If there are problems youcould not handle, we will send our technicians to your place and you are therefore, responsible for all thecost involved.

Q5: What about the payment method?

A5:T/T, L/C Paypal is available

Q6: What about after-sale service?

A6:12 months warranty for all kinds of products.

-

Large capacity trailer mobile impact crushing station limestone granite stone crushing stone crushing station price

-

gold mine electric rock crusher rock price

-

Vertical Shaft Impact Crusher Mechanism Sand Machine Manufacturer

-

Simple sand making sand line crusher hammer crusher mobile

-

China Hot Selling Quarry Crusher Manufacturer, Aggregate Stone Crusher Vertical Shaft Crusher VSI Sand Making

-

Stone sand making VSI artificial sand making machine price

-

artificial sand making machine, sand making machine, sand making equipment

-

PLFC 1250 VERTICAL SHAFT DRYER

-

Large Capacity Efficiency Fine Impact Crusher Rock Crusher Line Cone Crusher Price

-

Zenith Silica Sand Receiving

Other Products

-

$5500.00 - $6000.00 / unit

$5500.00 - $6000.00 / unit -

$4000.00 - $4500.00 / unit

$4000.00 - $4500.00 / unit -

$2800.00 - $3500.00 / unit

$2800.00 - $3500.00 / unit -

$80.00 / unit

$80.00 / unit -

$999.00 / set

$999.00 / set -

$4000.00 - $5700.00 / set

$4000.00 - $5700.00 / set -

$100000.00 / set

$100000.00 / set -

$3000.00 / set

$3000.00 / set -

$4000.00 - $4500.00 / set

$4000.00 - $4500.00 / set -

$1000.00 / set

$1000.00 / set