Factory Price Lab Mini Wool Carding Machine DW7010M

-

Supplier: Hefei Fanyuan Instrument Co., Ltd. -

Region: Anhui, China -

Contact: Ms MIN LIU -

Price: $5500.00 /set -

Min. Order: 1 set

| Package Preview: | ; | Port: | BY NEGOTIATION; |

| Applicable Industries: | Manufacturing Plant; | Product name: | Wool Carding Machine; |

| Power: | 2kw; | Application: | For cotton and wool; |

| Brand Name: | FYI; | Marketing Type: | New Product 2020; |

| Voltage: | 220V, 50Hz; | Warranty of core components: | 1 Year; |

| After-salesService Provided: | Engineers available to service machinery overseas; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union; |

| After-sales Service Provided: | Video technical support,Online support,Field installation, commissioning and training; | Dimension(L*W*H): | 1450*940*1360mm; |

| Showroom Location: | Indonesia,Bangladesh; | Machinery Test Report: | Provided; |

| Weight: | 350kg; | Local Service Location: | Indonesia,Bangladesh; |

| Place of Origin: | Anhui China; | Certification: | CE ISO; |

| Warranty: | 1 year,1 Year; | Condition: | New; |

| Automatic Grade: | Automatic; | Supply Ability: | 1000 Set/Sets per Year; |

| After Warranty Service: | Video technical support,Online support; | Video outgoing-inspection: | Provided; |

| Production Capacity: | 99%; | Packaging Detail: | Standard packaging of mini wool carding machine; |

| Core Components: | PLC,Engine; | Features: | Automatic; |

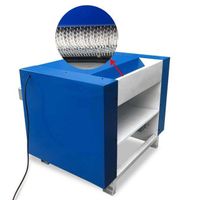

Lab Wool Carding Machine DW7010M

Application:

DW7010M Lab Wool Carding Machine is not only suitable for sheep wool, cashmere,but also perfect for alpaca hair, camel hair, yak hair and other animal fibers.

This lab wool carding machine is mainly work with Cylinder,working roller to open and card, after output by stripping roller,you can get the dehaired wool for wool batt (web).Working with this small wool carding machine,some coarse wool,dandruff and other impurities can be removed out, its work effect is perfect.

FEATURES of Lab Wool Carding Machine:

The mini wool carding machine is composed of frame of machine,flat curtain for feeding,licker-in, cylinder,working roller, stripping roller, doffer, chopper and so on.

(1). The frame parts are composed of a frame and a wall board, which is used for fixing all the rollers and the driving parts, supporting feet, motor and others,to ensure the smooth running of the machine.

(2). The flat curtain part is composed of a drive shaft, driven shaft, leather curtain and a transmission motor, so as to ensure the uniform feeding speed of the raw material.

(3). The licker-in parts is composed of roller, needle cloth, fixing seat,the spacing between licker-in roller and the front feeding roller is suitable.This parts is used to remove coarse wool and impurities.

(4). The cylinder parts composed of a roller,needle cloth, fixing seat and main motor. The spacing between cylinder and the front licker-in roller is suitable. And the spacing between working roller and stripping roller is also need to adjust.All about this will be well adjusted when the machines shipped to the Buyer.This part is mainly used to open raw materials.

(5). The working roller and stripping roller parts will working with cylinder, to open the wool again more fluffy.

(6). The doffer parts composed of a roller,needle cloth, fixing seat,the spacing between doffer and the front cylinder is suitable.to ensure that the wool on cylinder can be transferred to the next working roll.

(7). The chopper part is composed of a chopper arm, chopper holder and a chopper blade,which is the main used to strip the wool from doffer.

Details Pictures:

Key Specifications of Mini Wool Carding Machine:

|

Suitable Fiber |

Sheep wool,cashmere,alpaca hair,camel hair,yak hair, cotton and other animal fibers |

|

Capacity |

1-2 kg/h Depends on the raw materials and process requirements |

|

Working Width |

300mm |

|

Power |

Caring Machine:2kw |

|

Dimension(mm) |

1450*940*1360mm |

|

Weight |

Carding Machine:About 350 kg |

|

Diameter of Feeding Roller |

60mm |

|

Diameter of Lick-in |

200mm |

|

Diameter of Cylinder |

400mm |

|

Diameter of Doffer |

200mm |

|

Finished Product |

Fiber Tops or Fiber Batt |

|

Color |

Blue or White |

Installation in customer's lab Training in FYI showroom

1.Are your company a trading one or a factory?

Factory + trade (integration),30 years focusing on test instruments field,More than 10 years exporting experience.

2.After an order is placed, when to deliver?

Generally about 30 days, If we have inventory, we can arrange shipment within 7 days.

Please be aware that our production lead times depend on specific items and item quantities.

3.What about the warranty with after - sales services?

12 months warranty. Engineers available to sevice yarn dyeing machine overseas,after the warranty, the professional after-sale service team will provide perfect technical support on line,and help customer solve problems encountered while using our product, handles guest problems and complaints in a professional and timely.

4.What about the services and product' quality?

Each instruments must be carried out 100% quality examination and test when shipping and delivery goods. each of our product provide video training to show you how to install & operate. our products are widely recognized and trusted by users.

All the products meet with: ISO, ASTM, AATCC, BS, EN, DIN, JIS and other requireable standards.

♥ Want to know more information welcome to contact us now!

-

High quality electric wool polyester/needleloom machine

-

B272A Wool worsted wool fiber carding machine

-

Professional Textile Cotton Cards for Open-End Yarns

-

Tunisian Sheep Wool Yarn Cotton Fiber Fabric Textile Fully Automatic Mini Small Carding Machine

-

Combing machine with electric comb with small wool thread for sale

-

Bed quilt cotton fiber ball cotton rolling machine cotton fiber opening and carding machine quilt manufacturing machine

-

Combing machine with mini cotton thread for combing opening

-

Small alpaca carding machine for sale

-

Cotton Wool Rolling Machine Cotton Fiber Carding Machine Used Cotton Uncoiler For Clothes Recycling

-

Mini Worsted Yarn Fiber Wool Net Sliver Combing Machine Fabric Knitting Manufacturing Machine Textile Cotton Sheep Wool Carding Combing Machine

Other Products

-

$20000.00 - $25000.00 / set

$20000.00 - $25000.00 / set -

$8500.00 - $10000.00 / set

$8500.00 - $10000.00 / set -

$2500.00 / set

$2500.00 / set -

$8500.00 / set

$8500.00 / set -

$10000.00 / set

$10000.00 / set -

$5000.00 / set

$5000.00 / set -

$4000.00 / set

$4000.00 / set -

$3000.00 / set

$3000.00 / set -

$13000.00 / set

$13000.00 / set -

$15000.00 / set

$15000.00 / set