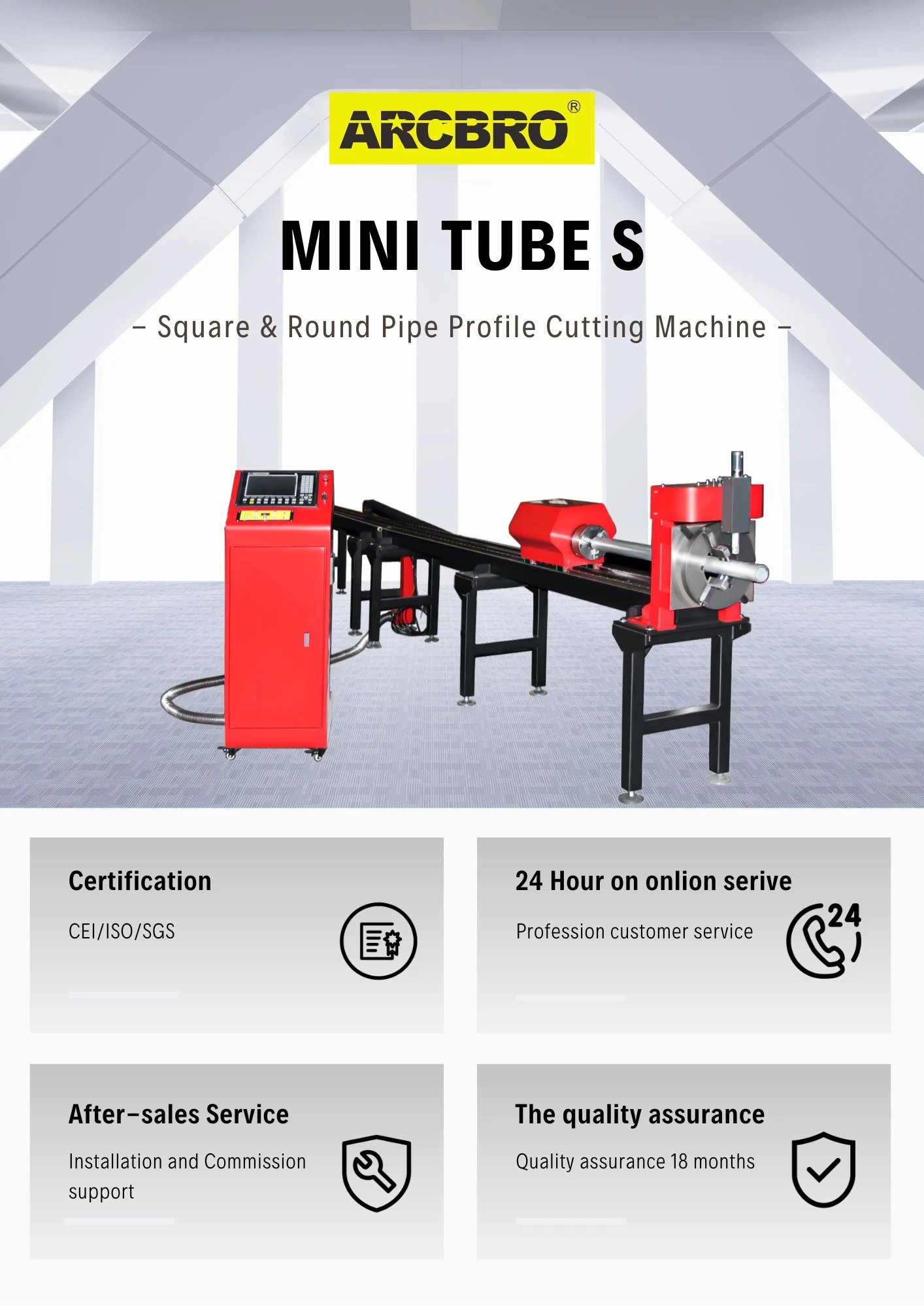

Hot selling Two-axis Mini Plasma Automatic metal tube Cut off machine with libellula software

-

Supplier: Beijing Arcbro Technology Ltd. -

Region: Beijing, China -

Contact: Mr Tony Leung -

Price: $11000.00 /set -

Min. Order: 1 set

| Brand Name: | ArcBro; | Marketing Type: | Ordinary Product; |

| Travel - Longitudinal: | 3m, 6m, 9m...(Extend in 3m); | Nesting software: | libellula tube; |

| Core Components: | Engine,Bearing,Gearbox,Motor,Gear; | Cutting mode: | Plasma; |

| Video outgoing-inspection: | Provided; | Key Selling Points: | High Productivity; |

| Cutting Speed: | 0-8000mm/min; | Warranty: | 2 years; |

| Package Preview: | ; | Automation: | Automatic; |

| Fume Extraction: | Custom quotes available upon request; | Product name: | Mini Tube S; |

| Type: | 2-axis; | Certification: | CE /ISO; |

| Port: | Tianjin, Dalian, Qingdao; | Temperature (operating): | 40-100°F (1-38° C); |

| Condition: | New; | Applicable Industries: | Hotels,Garment Shops,Building Material Shops,Machinery Repair Shops,Manufacturing Plant,Food & Beverage Factory,Farms,Restaurant,Home Use,Retail,Food Shop,Printing Shops,Construction works ,Energy & Mining,Food & Beverage Shops,Advertising Company; |

| Showroom Location: | United States,Germany,Peru,Chile; | Warranty of core components: | 1.5 years; |

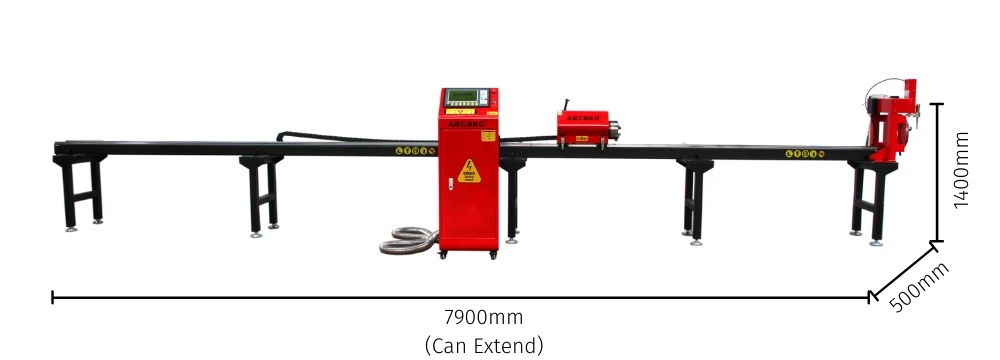

| Dimension(L*W*H): | 7900*500*1400mm; | Local Service Location: | United States,Germany,Peru,Japan,Chile; |

| Payment Terms: | L/C,T/T,Western Union; | After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; |

| After-sales Service Provided: | Free spare parts,Online support,Field installation, commissioning and training,Field maintenance and repair service,Video technical support; | Voltage: | 110V/220V; |

| Pipe Capacity: | 1.2-4.7in (25-120mm); | Weight (KG): | 660; |

| Linear Motion: | Precision rack and pinion; | Machinery Test Report: | Provided; |

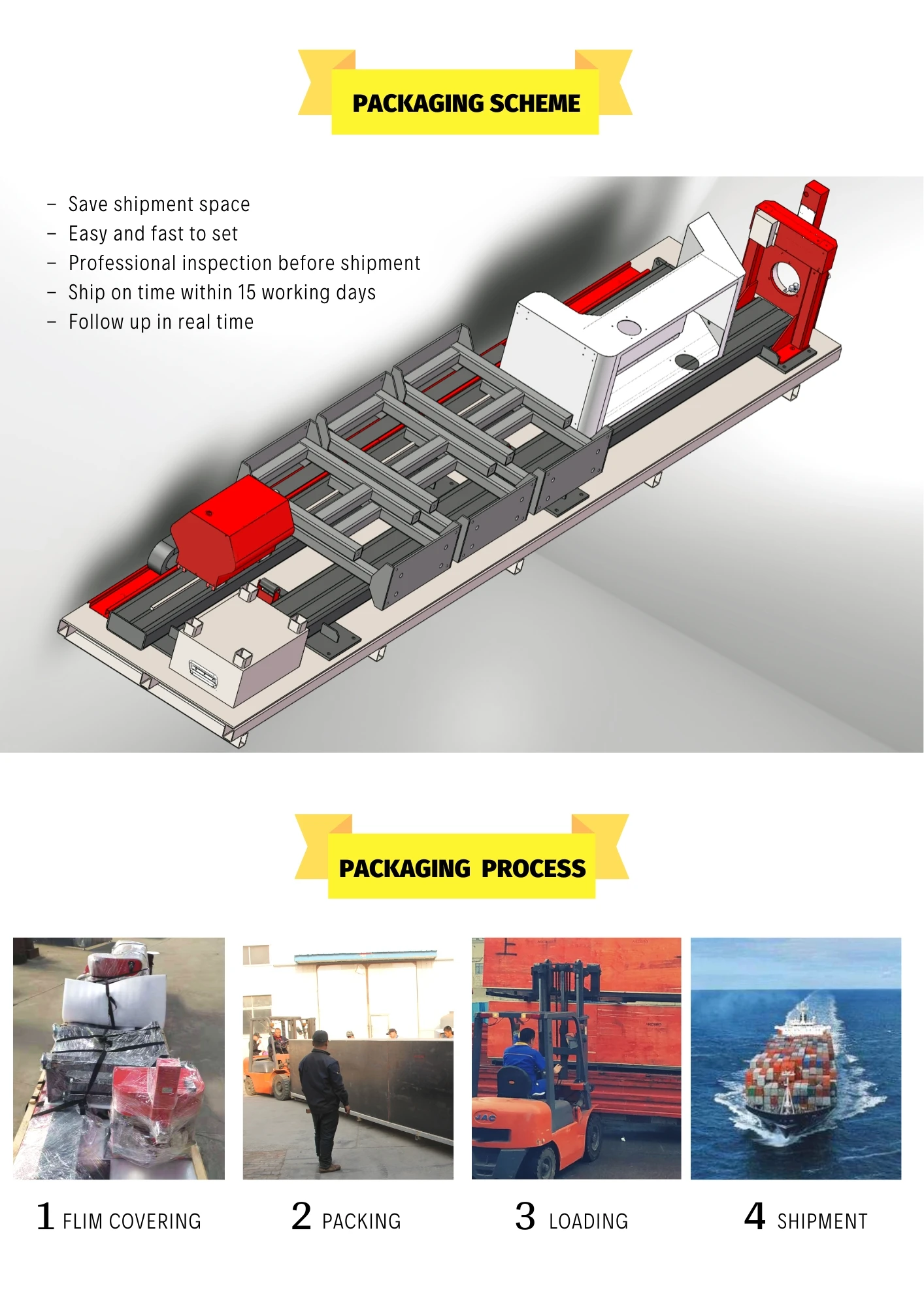

| Packaging Detail: | Safety plywood box; | Supply Ability: | 1000 Set/Sets per Month; |

| Year: | 2019; | Place of Origin: | Beijing China; |

| Material / Metal Processed: | Brass / Copper,Stainless Steel,Carbon Steel,Aluminium Alloy,ALLOY,Aluminum; |

Features:

The Mini-Tube-S by ARCBRO® is a affordable CNC round and square pipe cutting solution that comes in a compact footprint. It can do pipe OD from 30 to 120 mm and pipe length from 3000 to 15.000 mm by plasma. This two-axis CNC pipe cutting machine has a footprint of only 0.6m wide and can rapidly profile aluminum, stainless steel, and mild steel pipes with ease. User powerful and friendly Italy libellula software allows quick understanding and efficient use of Mini-Tube-S machines after a short training. NC data file transfer to Mini-Tube-S from CAD/CAM software available as option.

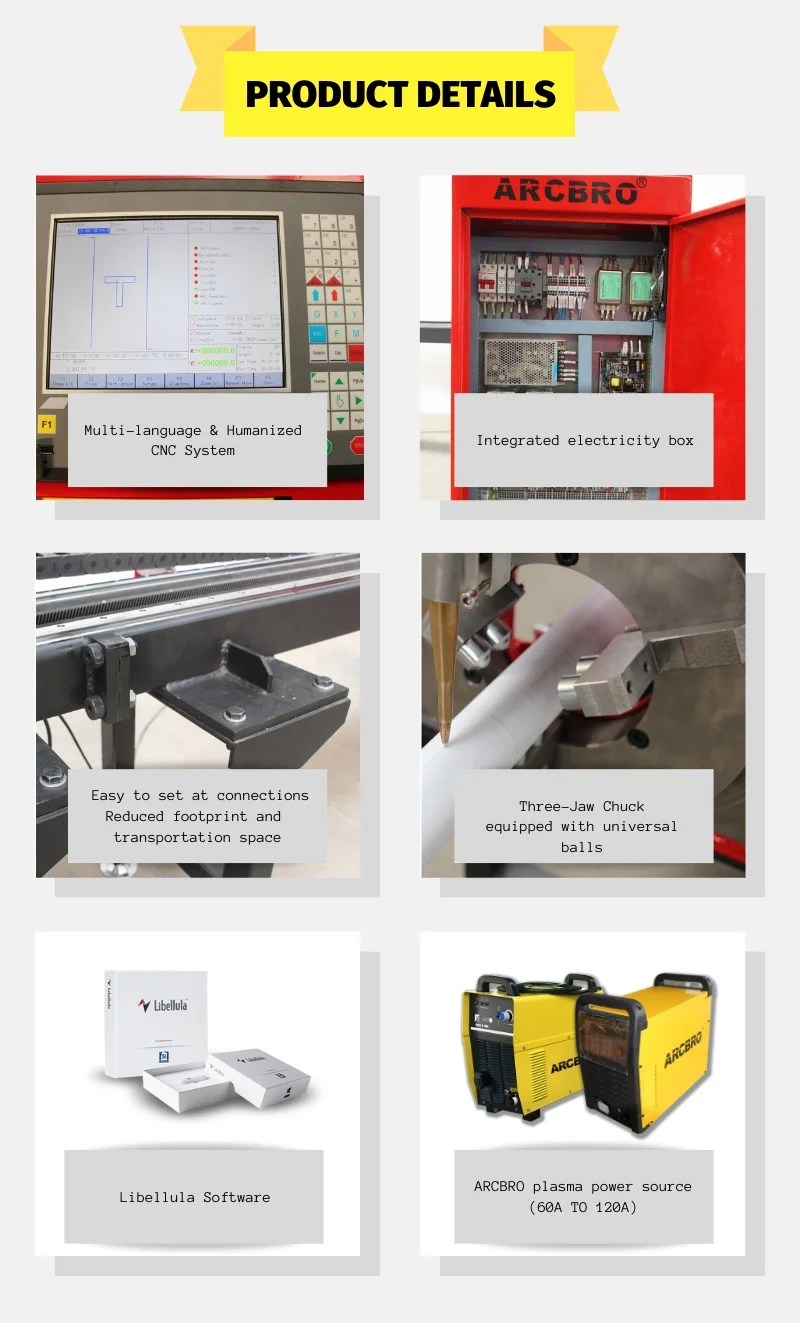

1, Advancing and stable motion control

-Open bed design with two chucks equipped with universal balls on a concentric circle. This design achieves the most accurate and stable motion control of the longitudinal and rotary axes.

-Automatic Arc Voltage Height Control adjusts the torch distance during cutting to profile the pipes and compensate for pipes that are out of round.

2, Top cutting quality

-Optimal cutting torch paths calculated by the Mini-TUBE-S control system ensures extremely accurate weld preparation.

-Advanced design and top quality components enable fast and efficient cutting with top quality results.

-After experimental measurement, the cutting tolerance is less than 0.3 with Panasonic high-quality servo motor, which can meet the tolerance requirements of all complex workpieces.

3,Frindly pipe loading and support system

-One button towing movement

-Support Yoke

The support yoke is designed to guide the tubing even if the material stock is not perfectly straight. It can be easily adjusted for different diameter by simply turning it.

-Pass Through Chuck

Pass through chuck will feed the tubing and also allows for pieces that are longer than the machine to be manufactured by allowing longer tubes to go through the chuck.

4,Italy Libellula tube nesting software

Libellula is a well-known brand for 30 years, and always the best cutting software for sheet metal processing. It is installed on our standalone, multilingual operating system.

-Research, versatility and ease of use: Libellula.TUBE is the software for cutting machines designed to program the cutting of tubes and profiles machines in an intuitive and immediate way.

-The design of parametric tubes occurs in real time: user can easily operate, and quickly learn to use the software thanks to the exclusive “Easy-use Experience”.

-The visualization of the model and geometric modifications performed on the entire piece or on particular individual parts is immediate and produces a list of the tools used, with the aim of being able to modify at a later time the individual parameters in a functional manner.

-The generated tubes can be of any shape and the tools used are parametric and customizable.

Parameters:

Application:

Material of pipe:

Carbon steel, stainless steel, aluminum,copper, other non-ferrous metals.

Type of cut:

Straight, Saddle, Multi-Miters, Tee, Lateral, Multi-saddles, Gusset slots, Double miter, Elbow support, Pipe to cone, Reinforcing pad, Bumpers, Overlaps

Packing & Shipping Service:

Payment:

4,After the warranty expires, the equipment enters the paid service period, and the manufacturer only charges the cost and transportation costs.

3,Free online staff training (also available directly to manufacturers); multi-language CNC trainers: support one-on-one training in English, Russian, Spanish

4,Free online technical support, technical consultation and machine diagnostics

5,Warranty period: Free replacement of any machine fault parts, free online machine diagnosis . After the warranty period, the manufacturer only charges the cost and freight.

1. Are you the manufacture?

Yes, we are. We are specializing in the plasma cutting area near 10 years. We have mature product lines. If you want to come andvisit, we absolutely welcome and we are willing to arrange the travel for you.

2. How to ensure transportation on time?

The customer can place an order in Alibaba, this is a third party and it will provide supervise and protect for buyer. If seller didn’t deliver the product in time, buyer can apply for a refund through the Ali platform to avoid losses.

3. How about payment terms?

The payment terms are optional, customer can choose at your convenience. [T/T, Alibaba Secure Payment, Western Union, Paypal, L/C]

4. How can i find a most suitable cutting machine?

We have most professional sales manager to help you choose the machine, and also, our strong engineer group will back up for anytechnology problems.

5. How about after-service?

Our warranty period is 18 months. If there is a problem with your machine during this period, we can provide the parts for free tosolve the problem. And customers who have reached a friendly transaction with us can enjoy lifelong technical support. If you needit, we can help you solve the problem through online communication, video and other means.

6. Is there any benefits for becoming a dealer?

Of course. If you have the strength and willingness to become our distributor, we will not only adjust the price. Secondly, we canprovide you with customized machines according to the sales habits of the buyer's market. More importantly, technically, we willsend professional engineers to give you on-the-spot guidance, so that you become the most understanding of the machine.

-

Pneumatic Circular Saw Metal Steel Pipe Cutting Machine

-

China Export Metal Stainless Steel Aluminum Copper Carbon Tube Cutting Machine

-

Sanitary pipe track type pipe cold cutting machine manual electric stainless steel pipe cutting machine

-

China made pipe cutting machine factory 425CNC cast iron water jet pipe automatic pipe cutting machine equipment

-

MC-275B 45 degree cutting semi-automatic circular saw pipe cutting machine

-

China Manual Circular Cold Saw Machine Pipe Cutter Cutting Machine

-

Automatic feeding CNC plasma pipe cutting machine Plasma pipe cutting machine

-

Cutting Pipe Saw for Orbital Weld Joint Preparation - ORS 115, Orbitec

-

RA3 Manual Type 1 - 1/2'', 2'' Light Duty High Precision Pipe Groover

-

High Precision Automatic Portable Welding Line Boring Machine

Other Products

-

$1100.00 / set

$1100.00 / set -

The Cheapest plasma cutter! Cut Cutting Air Metal Mini 60 Gas Cheap Small Portable CNC Plasma Cutter$1332.00 / set

The Cheapest plasma cutter! Cut Cutting Air Metal Mini 60 Gas Cheap Small Portable CNC Plasma Cutter$1332.00 / set -

$998.00 / set

$998.00 / set -

$1.00 / set

$1.00 / set -

$370.00 / set

$370.00 / set -

$1.00 / set

$1.00 / set -

$800.00 / set

$800.00 / set -

$1.01 / set

$1.01 / set