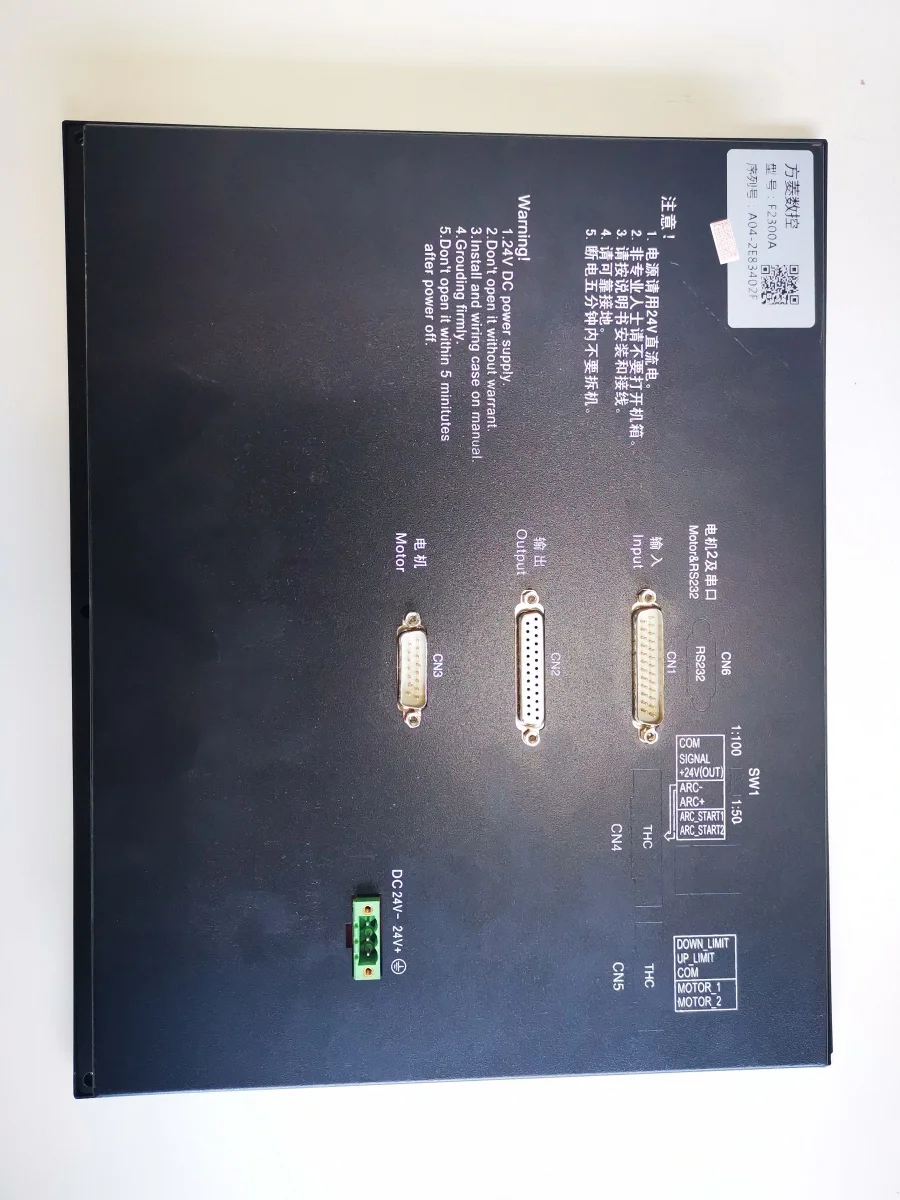

Shanghai Jiaoda F2300A CNC cutting machine controller system

-

Supplier: Beijing Arcbro Technology Ltd. -

Region: Beijing, China -

Contact: Mr Tony Leung -

Price: $370.00 /set -

Min. Order: 1 set

| Certification: | CE; | Warranty: | 1 year; |

| Application: | CNC Cutting machine; | Selling Units: | Single item; |

| Single package size: | 40X5X30 cm; | Brand Name: | Jiaoda; |

| Weight: | 3.5kg; | Condition: | New; |

| Single gross weight: | 4 KG; | Place of Origin: | China; |

| Applicable Industries: | Hotels,Garment Shops,Building Material Shops,Machinery Repair Shops,Manufacturing Plant,Food & Beverage Factory,Farms,Restaurant,Home Use,Retail,Food Shop,Printing Shops,Construction works ,Energy & Mining,Food & Beverage Shops,Advertising Company; | Dimension(L*W*H): | 352*42*284mm; |

| Technical indicators | |

| Number of control axes: | 2-axis linkage (customizable three-axis or four-axis) |

| Control accuracy: | ±0.001mm |

| Coordinate range: | ± 99999.99mm |

| Maximum pulse frequency: | 200KHz; maximum operating speed: 15m/min |

| Maximum number of program lines: | 80,000 lines |

| Maximum single program: | 4M |

| Time class resolution: | 10ms |

| System working power: | DC +24V DC power input, power is greater than 80W. |

| System working environment: | temperature -10 ° C to +60 ° C; relative humidity 0-95% without condensation |

| Drive arc voltage increase motor maximum power: | 45W (Note: only with T system). If you need more power, you can choose up to 200W. |

System Features

The system upgrade adopts the U disk upgrade mode, which is convenient, simple and practical, and provides lifetime upgrade service.

Parameter backup and parameter restoration

Supports 4 modes of oxygen gas, plasma, dusting and demonstration

Oxygen gas and plasma IO separate control

Oxygen gas is automatically adjusted, two-stage preheating, three-stage perforation

Plasma arc pressure feedback, positioning feedback, automatic closing of the arc voltage

Support edge cutting, reduce warm-up time for thicker steel plates

According to the thickness of the steel plate, the speed limit can be automatically set at the corner to effectively prevent overburning.

Manually select the starting line or select the punching point

Dynamic/static processing graphic display, graphic enlargement/reduction, dynamic tracking cutting point under magnification With power-off, breakpoint protection memory function

“Offset cutting” function can avoid the waste of board due to incorrect calculation of nesting

Different management rights and corresponding passwords can be set to protect the rights of equipment manufacturers.

Remote control that supports P2P mode or BCD (8421) and serial RS232 mode

Support laser point function

Support plasma dynamic perforation function

Statistics on processing piece count, running time, number of piercing, etc.

-

F2100B plasma controller + lifter kit F2100B+F1621+JYKB-100-DC24V-T3+F1510T for plasma cutting machine cutting machine

-

Dytrees CNC USB MACH3 100Khz output board mach3 board 4 axis motion driver interface controller

-

Absolute CNC remote control lathe and milling CNC servo system, similar to HNC and Fanuc

-

Reiz A11 DSP mobile phone repair service

-

A02B-0321-B530 0i-Mate MD/TD CNC Fanuc machine tool original system controller

-

DSP Controller Accessory Richauto A11 A18 B11 B18 8IO Interface Board

-

Dytrees Hot Sale CNC USB MACH3 100Khz Breakout Board 4 Axis Interface Driver Motion Controller

-

A02B-0281-C071/C072 18i-MB/TB CNC Fanuc machine tool original system controller

-

Cheap portable cnc plasma flame sheet metal cutting machine prices

-

GSK 980TDc 5-axis CNC controller for lathe and turn-mill CNC systems

Other Products

-

$1100.00 / set

$1100.00 / set -

$11000.00 / set

$11000.00 / set -

The Cheapest plasma cutter! Cut Cutting Air Metal Mini 60 Gas Cheap Small Portable CNC Plasma Cutter$1332.00 / set

The Cheapest plasma cutter! Cut Cutting Air Metal Mini 60 Gas Cheap Small Portable CNC Plasma Cutter$1332.00 / set -

$998.00 / set

$998.00 / set -

$1.00 / set

$1.00 / set -

$1.00 / set

$1.00 / set -

$800.00 / set

$800.00 / set -

$1.01 / set

$1.01 / set