YG automatic PET plastic bottle blowing water blowing machine price

-

Supplier: Henan Yugong Machinery Co., Ltd. -

Region: Henan, China -

Contact: Ms Jane Zhao -

Price: $25350.00 / 1 - 14 sets

$18990.00 / >=15 sets -

Min. Order: 1 set

| Maximum bottle height (mm): | 370 mm | Core components: | Gearboxes, pumps |

| Supply capacity: | 100 groups per week | Applicable industries: | Energy & Mining, Building Materials Stores, Construction |

| Blow molding type: | stretch blow molding | Showroom location: | not any |

| application: | bottle | Mechanical test report: | if |

| Key words: | Blow Molding Machine | payment terms: | L/C, D/P, D/A, T/T |

| size: | Length 1600*Width 900*Height 1600mm | Video outbound inspection: | if |

| color: | blue | Maximum bottle diameter (mm): | 220mm |

| Core component warranty: | 1 year | Weight (kg): | Chapter 560 |

| Marketing Type: | Hot Products of 2019 | Main selling points: | easy to operate |

| Warranty: | 1 year | Number of cavities: | 4 |

| Origin: | China | automation: | semi-automatic |

| Plastic processing: | PP, PC, ABS | Health status: | new |

| Power (kW): | 18 | port: | Shanghai or Qingdao |

| product name: | Blow Molding Machine | Function: | plastic bottle manufacturing |

| Suitable volume: | 200ml-2000ml | Hollow part volume: | custom made |

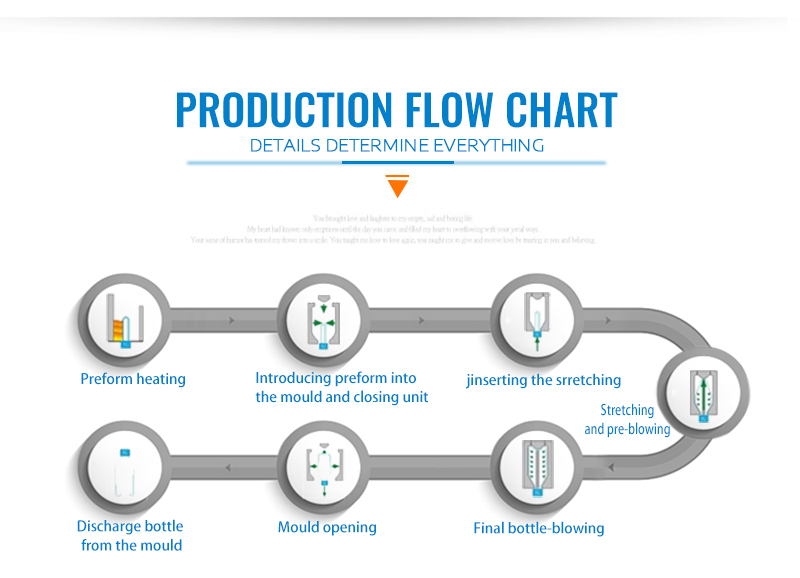

The semi-auto blow molding machine is suitable for producing PET plastic containers and bottles of 100ml-2000ml (2 cavities) or 2.5-3L (1 cavity), it has 1 infrared heater + 1 blower and 1 infrared heater + 2 blowers , depends on your budget and production speed requirements.

Widely used in the production of carbonated bottles, mineral water bottles, carbonated beverage bottles, pesticide bottles, oil bottles, cosmetic bottles, medicine bottles, wide-mouth cans, etc.

Double-crank mold adjustment, heavy-duty mold clamping, stable and fast, infrared oven is used to heat the preform, and the preform is heated evenly when rotating.

The air system is divided into two parts, the pneumatic action part and the bottle blowing part, to meet the different requirements of action and bottle blowing. It can provide sufficient and stable high pressure for blowing large shaped bottles.

-

Used good condition Joway JWM450 injection blow molding machine

-

Fully automatic injection blow molding machine PET PP PC cosmetic bottle stretching small led bulb injection blow molding machine

-

Economical 250ml amber vaccine vial plastic injection blow molding machine price

-

Machine for making 10 ml dropper bottles

-

Automatic bottle production machine

-

Easy to Operate Semi Automatic 5 Liter Semi Automatic Plastic Injection Blow Molding Machine

-

Plastic Bottle Blow Molding Machine Injection Molding Machine Plastic Bottle Making Machine

-

Automatic Pharmaceutical Plastic Bottle Injection Blow Molding Machine

-

China factory bulb plastic injection blow molding machine with best quality

-

PET semi-auto blow molding machine price

Other Products

-

$6388.00 - $7988.00 / set

$6388.00 - $7988.00 / set -

$35650.00 / set

$35650.00 / set -

$3980.00 / set

$3980.00 / set