Banbury Rubber Internal Mixer

-

Supplier: Qingdao Jiuzhou Jucai Machine Co., Ltd. -

Region: Shandong, China -

Contact: Mr edward cheng -

Price: $20000.00 /set -

Min. Order: 1 set

| heating / cooling: | steam heating / water cooling; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram; |

| tilting drive type: | worm gear pari drive / hydraulic drive; | Raw material: | rubber mixing , plastic mixing; |

| After-sales Service Provided: | Engineers available to service machinery overseas; | Main drive type: | left hand / right hand drive; |

| Key Selling Points: | Multifunctional; | Weight: | about 6000 kg; |

| Dimension(L*W*H): | 3200*1900*2950; | Model Number: | X(S)N-55; |

| After-sales Service Provided: | Field maintenance and repair service,Video technical support,Field installation, commissioning and training,Online support; | Certification: | ISO SGS CE; |

| Warranty: | Within 12 month; | Port: | any seaport in china; |

| Power(W): | 55 kw; | Applicable Industries: | Manufacturing Plant,Retail; |

| Supply Ability: | 30 Set/Sets per Month; | Brand Name: | JUCAI; |

| Condition: | New; | Place of Origin: | Shandong China (Mainland); |

| Type: | Rubber Kneader; | Packaging Detail: | machine will be packed intosmall wooden case or container; |

| Voltage: | As your local voltage; |

Rubber Dispersion Kneader

working volume : 1.5L,3L,5L,10L,20L,25L,35L,55L,75L,95L,110L,150L,200L,300L

Front roller speed : 30 r/min ,32 r/min ,40 r/min

Tilting drive type : worm gear pair drive , hydraulic drive

Main drive type : Left hand drive , right hand drive

Heating / cooling type : steam heating / water cooling ,warm water circulating heating / cooling ,electri heating / water cooling,oil heating / cooling

Gearbox type : Medium carbon alloy steel mid hard teeth gearbox / low carbon alloy steel hard teeth gearbox

Product Application

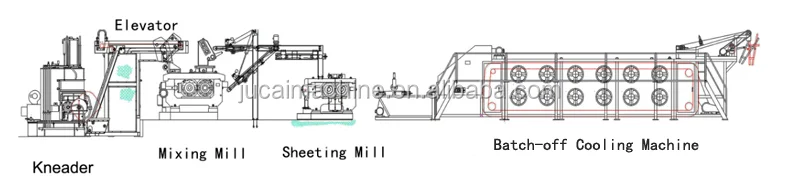

The series of rubber kneader machine is a type of dispersion kneader, consist of pneumatic control system, electric control system, tilting mechanism, mixing chamber, main driving system, dust sealing device, thermal resistance, rotor and cooling/heating system. You can choose the right model according to your needs. Below is the main technical parameters of the models

Machine feature

1. Pneumatic control system is controlled by PLC instruction . A bi-directional air cylinder make the ram up or down , in case thatoverload occurs in the mixing chamber ,the top ram can be raised automatically or manually if necessary , so as to protect motor from overload

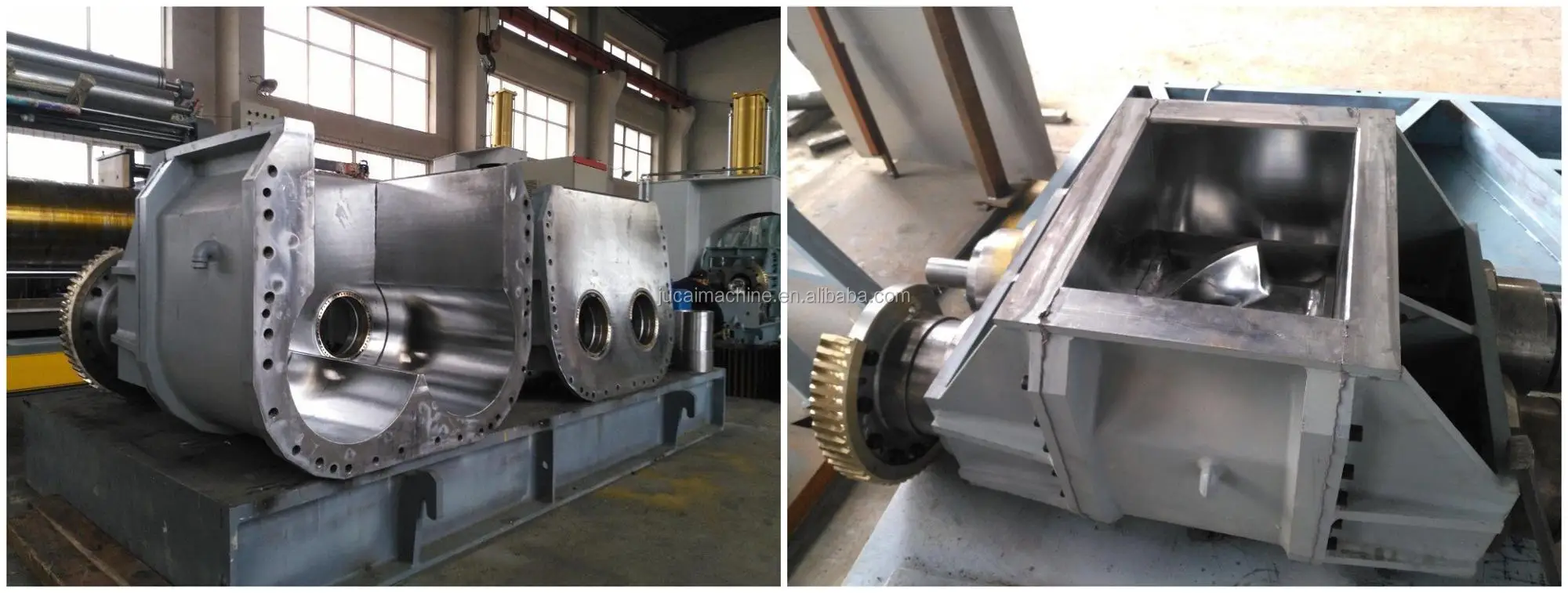

2.Tilting mechanism consists of brake motor , cycloidal gear reducer , TP type worm and worm gear etc . It is able to actuate the mixing chamber to tilte by 140 around the front rotor

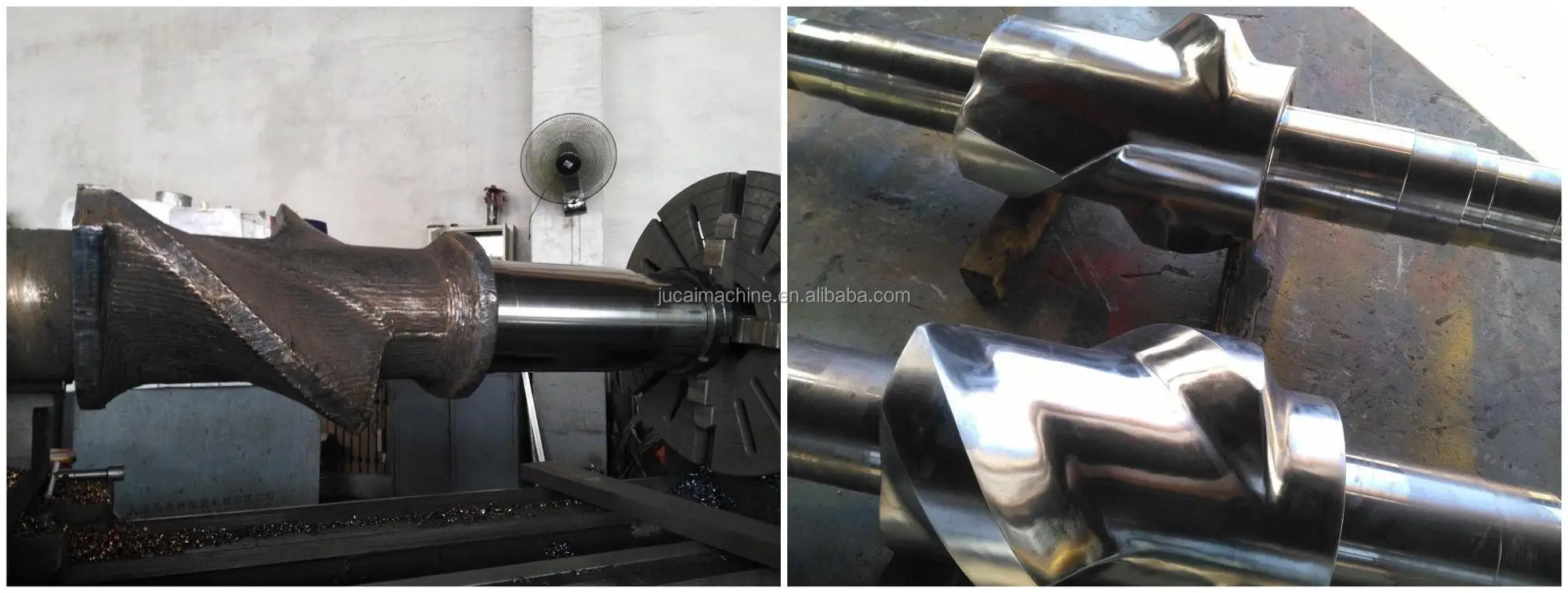

3.rotor shaft wing body top and wing corner are welded up with wear resistant alloy . rotor shaft surface ,the mixing chamber inner wall , upper ram surface and other surface connected with stock are hardened or polished and plated with hard chrome , or welded up wear resistant alloy welding , so they are wear resistant and corrosion resistant

4.rotor shaft is of integral structure rotor wing body welded on bored shaft , so it improves the strength and stiffness of the rotor . rotor inner wing vody cavity can be put through the cooling water or heating steam

5..mixing chamber is jacket type hollow structure . upper ram is hollow to increase cooling or heating area and the temperature control effect

6.main driving system consists of main motor ,reducer ,connecting gearbox odd-speed and face to face rotation of rotors is achived

7.electrical control system adopts the imported PLC device . All electronic components are imported or introduction technology products , to improve the reliability of the system.

1. We will design,manufacture,install and test the machines according to customers' requirement .Relevant personnel training for customers,ensure that customers fully grasp the use and maintenance of technology.

2 .Our service department listen to customers' feedback at any time and provide spare parts timely

-

Tangential rotor rubber mixer

-

Rear door type feed mixer/rubber raw material kneader

-

Spiral rubber kneader, EPDM hydraulic compression Banbury mixer, internal mixer

-

75L internal mixer rubber kneader closed internal mixer

-

Internal mixer plastic processing

-

Chemical batching system Powder weighing system PVC, rubber industry additive batching system

-

Latest design lab using rubber kneader or Banbury mixer for rubber and plastics

-

1L 3L 5L 10L Rubber Laboratory Banbury Internal Mixer Rubber Kneader Mixer Laboratory Powder Rubber Processing Test Machine

-

2L Experimental Kneader Rubber Dispersion Banbury Internal Mixer For Laboratory Testing Internal Mixer

-

Banbury Internal Mixer 50L/75L/150L/Rubber Industry

Other Products

-

-

$3000.00 / set

$3000.00 / set -

$6000.00 / set

$6000.00 / set -

$5000.00 / set

$5000.00 / set -

$4000.00 / set

$4000.00 / set -

$3000.00 / set

$3000.00 / set -

$6000.00 / set

$6000.00 / set -

$3000.00 / set

$3000.00 / set -

$3500.00 / set

$3500.00 / set -

$3000.00 / set

$3000.00 / set