100C 6T Hydraulic Lamination Hot Press for Glove Box

-

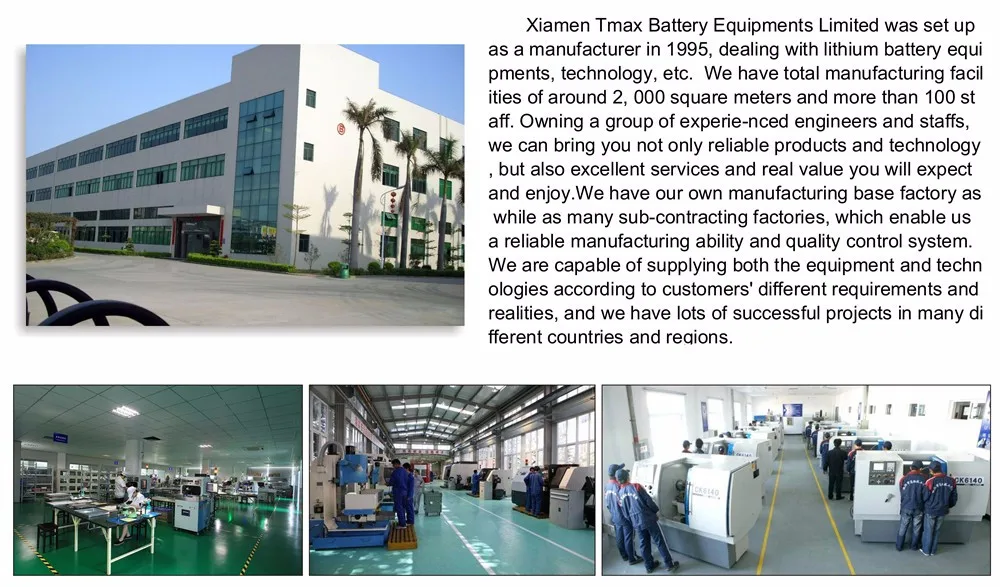

Supplier: Xiamen Tmax Battery Equipments Limited -

Region: Fujian, China -

Contact: Mr Aaron Huang -

Price: $1000.00 /set -

Min. Order: 1 set

| Certification: | CE; | Warranty: | 2 years; |

| Color: | Request; | Power(W): | 1200 W max; |

| After-sales Service Provided: | Engineers available to service machinery overseas; | Place of Origin: | China; |

| Condition: | New; | Packaging Detail: | 1 Standard exported package: Internal anticollision protection, external export wooden box packaging. 2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way. 3 Responsible for the damage during the shipping process, will change the damage part for you for free.; |

| Supply Ability: | 10000 Set/Sets per Month; | Max. Working Temperature: | 100°C Max. (<30 minnutes) 100°C continuous; |

| Brand Name: | TMAX; | Voltage: | 110VAC or 220VAC; |

| Type: | Hot Press; | Pressure: | 6 Metric Tone; |

| Application: | Glove Box; | Weight: | 120 lbs; |

| Port: | Xiamen Port; | Dimension(L*W*H): | Platen Area: 120mm x 120mm; |

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union; |

YLJ-HP60-LD is 100°C Max. compact lamination hot press consists of 6 metric ton hydraulic press with two heated platens (120x120mm area). The temperatures of the heated platens are controlled by digital temperature controller up to 100°C. The hot press is designed for preparing electrode & electrolyte of solid and flexible lithium battery.

SPECIFICATIONS:

Feature | · Heated platens are controlled by two digital temperature controller up to 200°C | ||||||||||

Heated Platen | · Platen Area: 120mm x 120mm · Made of Aluminium alloy with inserted heating element · Warning: Please don't press small area die directly against the soft Aluminium alloy surface. You may add hard steel plate on top and bottom if press small diameter die | ||||||||||

Max. Working Temperature | · 100°C Max. (<30 minnutes) · 100°C continuous | ||||||||||

Temperature Control | · Digital controller is installed in the control cabinet with 30-segment programmable and auto-tune function · Temperature accuracy ±1°C. | ||||||||||

Max. Working Pressure | · 6 Metric Tone (Note: the machine base must be secured to an unmovable & solid table before operation) | ||||||||||

Gauge Pressure Value to Force Conversion |

· Notes: o The actual force applied on the Hydraulic Cylinder (Ton) equal to the force applied on your working piece o For calculating the actual pressure (MPa) applied on your working piece, please follow the equations in below: § P = T/(πr^2) x g x 10 o P: Pressure (MPa) applied on your working piece o T: Force (Ton) applied on the Hydraulic Cylinder o g: Standard gravity. g ≈ 9.8 m/s2 o π: ~3.14 o r: Radius (cm) of the working piece o *1 Metric Ton = 1000 kg; 1 MPa ≈ 10 kgf/cm2 | ||||||||||

Power Requirement | · 110VAC or 220VAC +/-10%, 50/60Hz, single phase (please select the voltage in the selection bar) · 1200 W max,15A circuit breaker is required | ||||||||||

Option | · Optional: Upgrade to Digital Vacuum/Pressure Gauge (100Kp to 30Mp) with Max. Pressure Setting. · Optional: NIST certificate Load cell Pressure Calibration Kit to measure the actual force | ||||||||||

Compliance | · CE Certified | ||||||||||

Shipping Size Weight | · 120 lbs | ||||||||||

Warranty | · Two years limited standard warranty | ||||||||||

Application Notes | · The testings of solid lithium battery requires the cell assembly to be compressed and pressure maintained in order to ensure the good conductivity between the electrode and solid electrolyte. The use of such hot press is ideal for maintaining a constant pressure for the cell, in addition, interface conductivity can be increased under the elevated temperature condition. Please view the pictures below to order the necessary materials for solid lithium battery tests. |

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME:15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity.

1.Which procedure to secure your Quality?

1.Order processing?

2. Shipping methods?

1 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

2 Responsible for the damage during the shipping process, will change the damage part for you for free.

3.Order tracking?

Online order can be tracked by login to your account. Please allow 24 hours after order is shipped to see logging details.

If you need a tracking number for your order, please send an email to us with your order/invoice number.

4. Import/export tax, duty, GSM, Customs Clearance, and etc?

All import/export related expenses are sole responsibility of the buyer; charges will vary from country to country. Please consult with your local import experts or transportation carrier for more details.

5.Lost or Stolen packages?

Please report all lost or stolen packages to us at the earliest possible time. An investigation will be open soon after reporting the incident to us, and a final ruling will be issued by the carrier for the claim after 10-15 business days. A replacement package will be sent as soon as the claim is accepted by the responsible carrier.

-

Wooden door cold pressing woodworking machine wood refrigeration oil press

-

Factory Price MH3248*50T Plywood Door Production Line Hydraulic Cold Press Machine

-

Woodworking hydraulic heat press 200 tons

-

Furniture cold press machine 3000mmx1500mm / Plywood cold press machine

-

Wholesale veneer hot pressing equipment

-

120 tons woodworking machinery door heat press XBD-BY214-120T

-

hot press melamine laminating machine

-

120 ton wood hydraulic plywood hot press machine

-

Shiny 15 ply plywood veneer heat press machine

-

Automatic Heat Press Vacuum Film Press Vacuum Press

Other Products

-

$2090.00 / set

$2090.00 / set -

$5200.00 / set

$5200.00 / set -

$890.00 / set

$890.00 / set -

$900.00 / set

$900.00 / set -

$3000.00 / set

$3000.00 / set -

$980.00 / set

$980.00 / set -

$800.00 / set

$800.00 / set -

$890.00 / set

$890.00 / set -

$1000.00 / set

$1000.00 / set -

$1600.00 / set

$1600.00 / set