API certificated sucker rod centralizer/high quality oilfield api spiral type sucker rod

-

Supplier: Puyang Zhongshi Group Co., Ltd. -

Region: Henan, China -

Contact: Mr Jincheng Zhang -

Price: $10.00 / >=10 pieces -

Min. Order: 10 pieces

| Packaging Detail: | wooden case; | Supply Ability: | 50000 Piece/Pieces per Month Sucker Rod Centralizer; |

| Use: | centralizing sucker rod; | Model Number: | ZS8152; |

| Size: | 5/8'' 3/4'' 7/8'' 1'' 1-1/8''; | Product name: | sucker rod centralizer; |

| Type: | sucker rod centralizer; | Payment Terms: | L/C,T/T,Western Union; |

| Port: | QINGDAO; |

Parameter of sucker rod guide:

Size | Rod D.(in) | Thread D.(in) | Length of pin(mm) | Length of wrench(mm) | Width of Wrench (mm) | Length of rod(ft) |

5/8 | 5/8 | 15/16 | 31.75 | ≥ 31.8 | 22.20 | 2 / 4 /6 / 8 /10/25/30 |

3/4 | 3/4 | 1-1/16 | 36.50 | ≥ 31.8 | 25.40 | 2 / 4 /6 / 8 /10/25/30 |

7/8 | 7/8 | 1-3/16 | 41.28 | ≥ 31.8 | 25.40 | 2 / 4 /6 / 8 /10/25/30 |

1 | 1 | 1-3/8 | 47.63 | ≥38.1 | 33.30 | 2 / 4 /6 / 8 /10/25/30 |

1-1/8 | 1-1/8 | 1-9/16 | 53.98 | ≥41.3 | 38.10 | 2 / 4 /6 / 8 /10/25/30 |

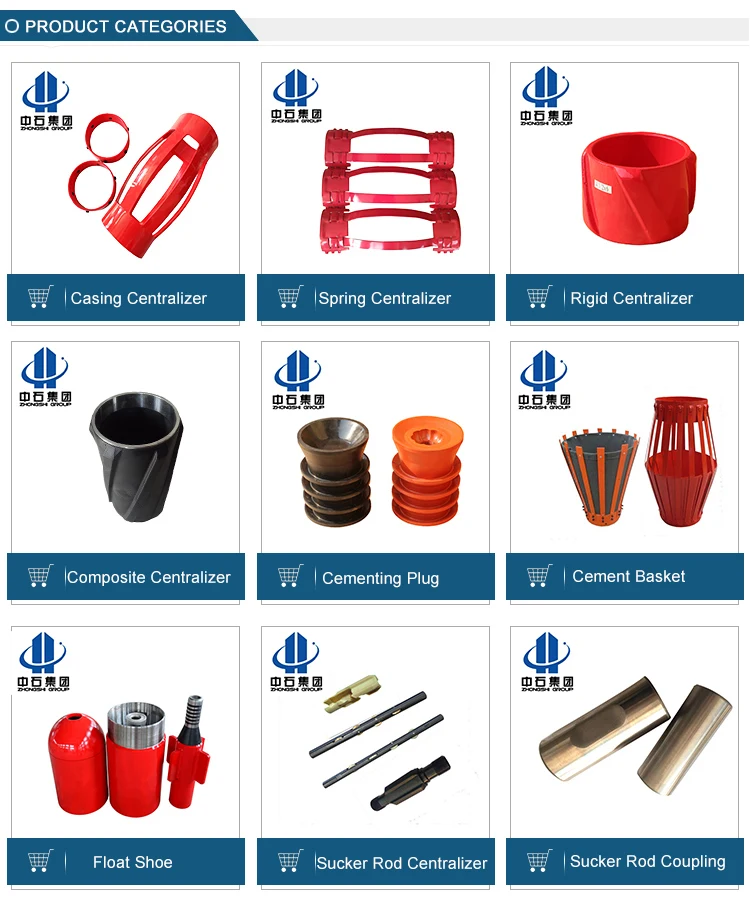

Sucker rod centralizer:

1) Standard: API 11B

2) API and ISO certified

3) Specification: 5/8-1 3/4"

4) Type: Coupling Sucker Rod Guide

Sucker rod centralizer is used in pumping well, it's a tool which can set upright the sucker rod, and protect the sucker rod wiping with tubing pipe.

Application:

Rod up and down inside the tubing activity, due to the elastic deformation of sucker rod, rod and oil tube wall is easy to produce friction, sucker rod break off easily, sucker rod centralizer has strong flexibility, it contact with the pipe wall, can reduce the friction of rod and tube, enhance the production life of pumping unit.

By centralizing the rod, the sucker rod guide acts as a wear resistant bushing, preventing the rod from wearing through the production tubing. Rod and production tubing contact is increased in deviated wells and horizontally drilled unconventional shale wells. Rod guides, used in wells with server deviation or with pumps set beyond the kickoff point in horizontally drilled wells, increase mean time between failure, decrease artificial lift cost, and increase well profitability.

Structure:

Sucker rod centralizer is composed of collar, centering sleeve and nipple.

Working theory:

It connect with sucker rod, the centralizer casing OD is larger than the sucker rod coupling OD in order to centralizer rod. Centralizer casing has high strength wear resistant, so when contact with oil tube, makes the centralizer body wearing and reduces oil tube wearing so as to anti-wear (centralizer casing temperature resistant: 260°C, material: self-lubricating Ni-p plating material). The steel surface adopt Ni-p plating (the anti-corrosion technology) makes the centralizer has the ability of anti-wear and anti-corrosion. And it also suitable for the worse corrosion well condition.

How to work

It connect with sucker rod, the centralizer casing OD is larger than the sucker rod coupling OD in order to centralizer rod. Centralizer casing has high strength wear resistant, so when contact with oil tube, makes the centralizer body wearing and reduces oil tube wearing so as to anti-wear (centralizer casing temperature resistant: 260°C, material: self-lubricating Ni-p plating material). The steel surface adopt Ni-p plating (the anti-corrosion technology) makes the centralizer has the ability of anti-wear and anti-corrosion. And it also suitable for the worse corrosion well condition.

-

API arch type case centralizers

-

Downhole tool sucker rod guide device

-

API oil field aluminum spiral blade centralizer

-

API 11B pumping unit sucker rod coupling

-

Cam-loc Swivel Anchor 4 1/2" * 2 3/8" EU 8RD API Standard Oil & Gas Equipment

-

Puyang factory wheel roller guide / sucker rod centralizer sucker rod

-

New Arrival Bow Spring Centralizer/Drilling Tool

-

API standard casing centralizer stop ring, oil well centralizer stop ring

-

portable pressure washer, rated 1800 STG-A1

-

casing centralizer

Other Products

-

$25.00 / piece

$25.00 / piece -

$35.00 / piece

$35.00 / piece -

$5.00 / piece

$5.00 / piece -

$5500.00 / set

$5500.00 / set -

$10.00 / piece

$10.00 / piece -

$25.00 / piece

$25.00 / piece