High quality API spring centralizer good price

-

Supplier: Puyang Zhongshi Group Co., Ltd. -

Region: Henan, China -

Contact: Mr Jincheng Zhang -

Price: $25.00 /piece -

Min. Order: 1 piece

| Package Type: | Plywood case; | Fast delivery: | Yes; |

| Surface: | powder Baking; | Private Label: | Yes; |

| Low Starting Force: | Yes; | Single package size: | 22X21X35 cm; |

| Applicable Industries: | Manufacturing Plant; | Type: | Casing centralizer; |

| Material: | Steel/ALuminum/Nylon etc; | Model Number: | 7*8.5; |

| Color: | red or as request; | Delivery Detail: | 0 days after payment; |

| Selling Units: | Single item; | Single gross weight: | 4 KG; |

| High Restoring Force: | Yes; |

Main Features:

1.API 10D certified manufacturer

2.Widest Range of Centralizers

3.Exceeds API Requirements

4.Available in sizes 4-1/2" to 20".

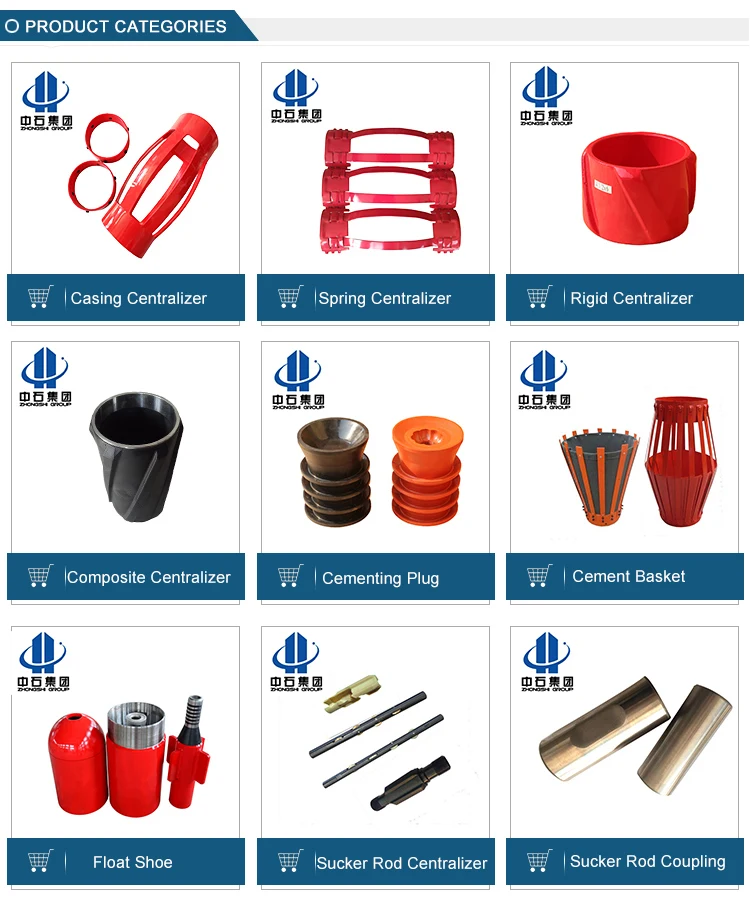

Casing Centralizer is a device used to place the casing at the center of the hole so as to improve the efficiency of the cementing. It is an important device because if the Casing Centralizer touches the formation at any part of the hole, then cement slurry does not pass through the area of the contact resulting in a poor cementing job.

The primary job of Casing Centralizers is to effectively spread the cement in the well casing. There are various types of Casing Centralizers used in the industry, but these are the four primary types of centralizers:

Bow-Spring Centralizer – This type of centralizer is a bow-shaped metal strip used to centralize the casing in a borehole so as to improve the efficiency of cementing.

Rigid Centralizer – This type of centralizer is built using steel or cast iron and works well with the deviated wellbores. It is not as effective as bow-spring centralizers.

Semi-Rigid Centralizer – This type of centralizer is made from double-crested bows that have both the features of bow springs and rigid centralizers.

Mold on Centralizer – This type of centralizer is made from carbon fiber ceramic materials and can be used directly to the casing surface.

With the energy industry’s challenging and demanding performance requirements, Our Centralizer Subs are designed to withstand the most extreme deepwater down hole conditions. Additionally, Our customization capabilities allow the sub design to match the exact needs of most well and casing

programs.

NO. | Size (in) | ID(mm) | Height (mm) | OD (mm) |

1 | 5-1/2”*7” | 142-148 | 305 | 215 |

2 | 5-1/2”*8-1/2” | 142-148 | 305 | 225 |

3 | 6”*8-1/2” | 156-158 | 305 | 235 |

4 | 7”*8-1/2” | 181-186 | 400 | 235 |

5 | 7”*9-5/8” | 181-186 | 400 | 255 |

6 | 7-5/8”*9-5/8” | 197-201 | 400 | 275 |

7 | 9-5/8”*12-1/4” | 250-255 | 650 | 330 |

8 | 13-3/8”*17-1/2” | 342-347 | 650 | 450 |

-

API arch type case centralizers

-

Downhole tool sucker rod guide device

-

API oil field aluminum spiral blade centralizer

-

API 11B pumping unit sucker rod coupling

-

Cam-loc Swivel Anchor 4 1/2" * 2 3/8" EU 8RD API Standard Oil & Gas Equipment

-

Puyang factory wheel roller guide / sucker rod centralizer sucker rod

-

New Arrival Bow Spring Centralizer/Drilling Tool

-

API standard casing centralizer stop ring, oil well centralizer stop ring

-

portable pressure washer, rated 1800 STG-A1

-

casing centralizer

Other Products

-

$25.00 / piece

$25.00 / piece -

$35.00 / piece

$35.00 / piece -

$5.00 / piece

$5.00 / piece -

$5500.00 / set

$5500.00 / set -

$10.00 / piece

$10.00 / piece -

$10.00 / piece

$10.00 / piece