API standard hinged non-welded casing centralizer

-

Supplier: Puyang Zhongshi Group Co., Ltd. -

Region: Henan, China -

Contact: Mr Jincheng Zhang -

Price: $25.00 /piece -

Min. Order: 1 piece

| Size: | 4 1/2"-20"; | Color: | Red or as request.; |

| High Restoring Force: | Yes; | Core Components: | 正唐庄; |

| Single gross weight: | 5.0 KG; | After Warranty Service: | Video technical support,Online support,Spare parts; |

| Place of Origin: | China; | Machinery Test Report: | Provided; |

| Brand Name: | zs; | Video outgoing-inspection: | Provided; |

| Marketing Type: | Hot Product 2019; | Condition: | New; |

| Samples: | Available; | Type: | Spring centralizer; |

| Selling Units: | Single item; | Material: | Alloy Steel; |

| Local Service Location: | None; | Warranty: | 1 Year; |

| Fast delivery: | Yes; | Single package size: | 20X20X35 cm; |

| Showroom Location: | None; | Model Number: | 7''x8.5''; |

| Features: | One piece; | Certificate: | API; |

| Low Starting Force: | Yes; | Packaging Detail: | plywood case; |

| Applicable Industries: | Construction works ; | Warranty of core components: | 1 Year; |

FEATURES:

1.Interlocking Design Between End Collar and Bow Spring

2.Meeting or Even Exceeding API

3.Available With Standard or Semi Rigid Non Welded Centralizer and Turbolizer

4.Low Running Force and High Restoring Force are vital to casing running operation

5.Applied in Casing Sizes from 4-1/2 to 20inch

describe:

1.Designed and manufactured as per API.

2.Non Weld Bow centralizers are used to position the casing in the center of the wellbore in vertical, deviated as well as horizontal wells.

3.The Non Weld Bow Centralizers combine the highest Non Weld Centralizer restoring force with the lowest starting force.

4.High quality Bows made of special alloy steel with uniform hardness provide optimum performance.

5.The bows with extended profile prevent them from hitting against casing collars.

6.Hinge locking pins are of high strength steel for maximum structural robustness .

7.Bows are then Flattened several times on a special machine to get permanent setting.

8.Centralizers undergo a special process of rust prevention before powder coating.

9.The Non Weld Bow spring centralizers are available in sizes 4-1/2" to 20".

|

NO. |

Size (in) |

ID(mm) |

Height (mm) |

OD (mm) |

|

1 |

5-1/2”*7” |

142-148 |

305 |

215 |

|

2 |

5-1/2”*8-1/2” |

142-148 |

305 |

225 |

|

3 |

6”*8-1/2” |

156-158 |

305 |

235 |

|

4 |

7”*8-1/2” |

181-186 |

400 |

235 |

|

5 |

7”*9-5/8” |

181-186 |

400 |

255 |

|

6 |

7-5/8”*9-5/8” |

197-201 |

400 |

275 |

|

7 |

9-5/8”*12-1/4” |

250-255 |

650 |

330 |

|

8 |

13-3/8”*17-1/2” |

342-347 |

650 |

450 |

-

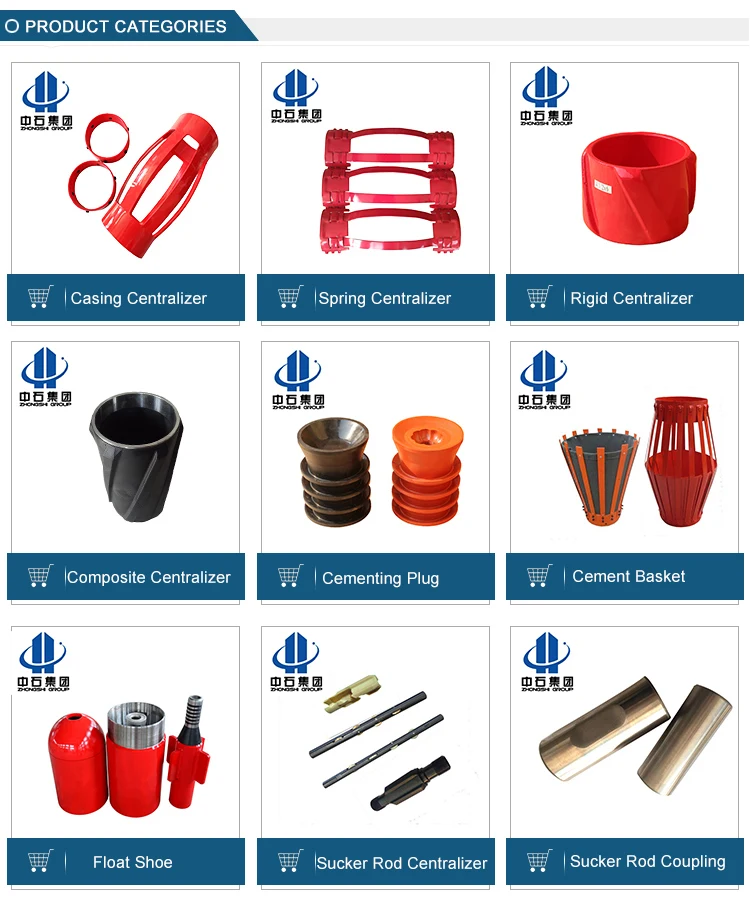

API arch type case centralizers

-

Downhole tool sucker rod guide device

-

API oil field aluminum spiral blade centralizer

-

API 11B pumping unit sucker rod coupling

-

Cam-loc Swivel Anchor 4 1/2" * 2 3/8" EU 8RD API Standard Oil & Gas Equipment

-

Puyang factory wheel roller guide / sucker rod centralizer sucker rod

-

New Arrival Bow Spring Centralizer/Drilling Tool

-

API standard casing centralizer stop ring, oil well centralizer stop ring

-

portable pressure washer, rated 1800 STG-A1

-

casing centralizer

Other Products

-

$35.00 / piece

$35.00 / piece -

$5.00 / piece

$5.00 / piece -

$5500.00 / set

$5500.00 / set -

$10.00 / piece

$10.00 / piece -

$10.00 / piece

$10.00 / piece -

$25.00 / piece

$25.00 / piece