Iso Certificated Gold Stone Mining Bentonite Zircon Sand Stone Grinding Wet Ball Mill

-

Supplier: The Nile Machinery Co., Ltd. -

Region: Henan, China -

Contact: Ms Lily Li -

Price: $60500.00 /set -

Min. Order: 1 set

| Core Components: | MOTOR; | Warranty of core components: | 1 YEAR; |

| Dimension(L*W*H): | according to the model; | Marketing Type: | New Product 2020; |

| OEM: | Yes; | Balls Weight: | 3.5t; |

| Place of Origin: | Henan China; | Capacity(t/h): | 4-12; |

| Motor Type: | AC motor; | Supply Ability: | 200.0 Set/Sets per Month; |

| Showroom Location: | kenya; | Video outgoing-inspection: | Provided; |

| Warranty: | 1 YEAR; | Applicable Industries: | Building Material Shops,Energy & Mining; |

| Port: | QingDao; | Type: | ball mill; |

| Effective volume: | 4.7m3; | Certification: | ISO CE; |

| Color: | Customerized; | Local Service Location: | kenya; |

| Feeding size: | 25mm; | Keywords: | Ball mill; |

| Machinery Test Report: | Provided; | Condition: | New; |

| Weight: | 9.5t; | Packaging Detail: | Ball mill will be packed into one 20 ft container or 40 ft container.; |

| Payment Terms: | L/C,T/T; | After-sales Service Provided: | Online support; |

| Brand Name: | The Nile; |

Iso Certificated Gold Mining Bentonite Zircon Sand Stone Grinding Wet Ball Mill

The ball mill is a cylinder tube mill, which is characterized by high grinding efficiency single large capacity, low power consumption and little dust pollution. It is commonly used in closed-circuit milling and open flow milling in the field of cement, fly ash, a variety of non-metallic materials dry milling production.

Working principle

The ball mill is horizontal cylindrical rotation device,driving by brim gearwheel, there are two chambers and grid. Material goes into the first chamber through the feeding inlet, inside the first chamber, there are stage liners and ripple liners as well as steel balls with various kinds.The shell rotates which generates eccentricity, this force brings balls to a certain height and then balls drop down by gravity, which will impact and grind the material. After the primary grinding in the first chamber, material goes into the second chamber through segregate screen, in the second chamber, there are fiat liners and steel balls, after the secondary grinding, material is discharged through the discharge screen.

Main features

1. The lining can be replaced.

2. Mineral ball mill is an efficient tool for grinding many materials into fine powder.

3.Two ways of grinding: the dry way and the wet way.

4.Ultimate particle size depends entirely on how hard the material you’re grinding is.

5. As the barrel rotates, the material is crushed between the individual pieces of grinding media that mix and crush the product into fine powder over a period of several hours.

| Model NO. |

Balls Weight (t) |

Max. Feeding Size (mm) |

Capacity (t/h) |

Main Reducer |

Motor Power (kw) |

Weight (t) |

| 1200*4500 | 6.5 | 25 | 1.4-2 | ZD30 | 45 | 13.1 |

| 1500*5700 | 13 | 25 | 3.5-4.5 | ZD40 | 130 | 24 |

| 1830*6400 | 21.6 | 25 | 5.5-6.5 | ZD60 | 210 | 38 |

| 2200*7000 | 23.5 | 25 | 6-7 | ZD60 | 210 | 43 |

| 2200*6500 | 31.5 | 25 | 8-10 | ZD70 | 380 | 50.2 |

| 2200*7500 | 36 | 25 | 10-11 | ZD70 | 380 | 53.2 |

| 2200*8000 | 39 | 25 | 10-12 | ZD70 | 380 | 55 |

Standard package in wooden boxes or containers.

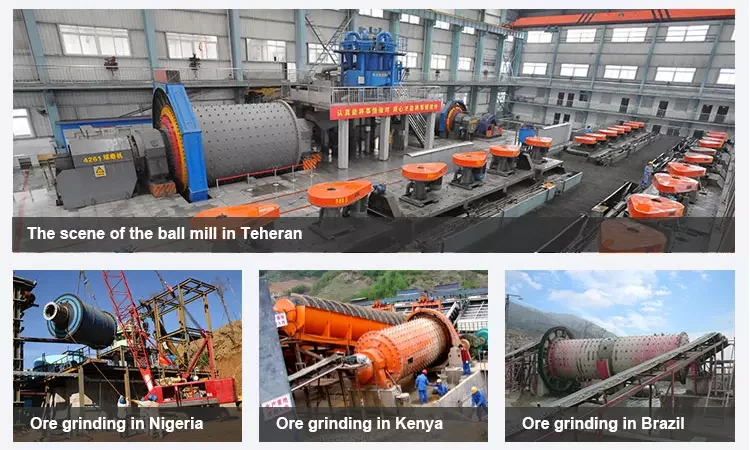

The Nile Co.,Ltd.is committed to designing,producing grinding mills,crushers,conveyors,feeding machine,drying and calcinating as well as beneficiation equipments,fine sand recyling equipment etc,which are widely applied in electricity,metallurgy,mine and quarry ,wharf,granary,chemical industry.Our products have been spreaded all over China,and also exported to

European,American,Asian,African countries and enjoyed great popularity among our customers.

Our company owns an experienced and skilled sales and service team which compose a perfect service network.We will send the professional engineers to the installation sites and provide guidance for the installation,commissioning and initial run as well as planning administration of the equipments after purchase.

Every year, we export our grinders and crushers to South Asia, Africa, South America, middle East and other regions. Our Machines enjoy a high reputation in the foreign market. You are very welcomed to visit our factory, and hope there are chance for us to have a long term cooperation.

Pre-sale services:

(1) Advice of model choice.

(2) Design and manufacture machines according to customer's special requirements

(3) The company is free of charge to the user on-site engineering and technical personnel planning site for the user to design the best processes and program

After-sale services :

(1) Arrange technicians to go to the site to guide installation

(2) If your machine is out of warranty period, you can go to the Nile's overseas office to buy spare parts.

(4) complete sets of equipment installed, 1-2 full-time technical staff to stay free of charge to help customers on-site production of 1 month, until the user' satisfaction.

Q1: Are you factory or trade company?

A1: We are factory.

Q2: Where your products have been exported before?

A2: Our products have been sold to South Asia, Africa, South America, middle East and so on.

Q3: How will you help the customer to install the equipment?

A3: Our senior engineer will guide the installation and commissioning as well as the initial production at

Q4: How about the wear parts supply?

A4: We offer wear parts to our customer with our most favorable price. If there are problems youcould not handle, we will send our technicians to your place and you are therefore, responsible for all thecost involved.

Q5: What about the payment method?

A5:T/T, L/C Paypal is available

Q6: What about after-sale service?

A6:12 months warranty for all kinds of products.

-

High efficiency rock gold grinding equipment wet disc grinder for sale

-

Professional 1000 tons/day cement grinding station ball mill price

-

Black graphite vibrating ball mill

-

Nano powder steel ball mill grinder laboratory grid ball mill with grinding ball grinder

-

Small gold ore mill, small wet mill, small gold ore mill

-

Diesel engine ball mill for gold mine development for sale

-

1600 gold mill with gearbox, china wet disc mill for sale

-

Superfine Powder Complete Production Line Fluidized Bed Jet Mill

-

Energy-saving gold mine rock crusher quartz gold ore stone mill small gold ball mill

-

1100 wet mill reducer 400 gears

Other Products

-

$5500.00 - $6000.00 / unit

$5500.00 - $6000.00 / unit -

$4000.00 - $4500.00 / unit

$4000.00 - $4500.00 / unit -

$2800.00 - $3500.00 / unit

$2800.00 - $3500.00 / unit -

$80.00 / unit

$80.00 / unit -

$999.00 / set

$999.00 / set -

$4000.00 - $5700.00 / set

$4000.00 - $5700.00 / set -

$100000.00 / set

$100000.00 / set -

$3000.00 / set

$3000.00 / set -

$4000.00 - $4500.00 / set

$4000.00 - $4500.00 / set -

$1000.00 / set

$1000.00 / set