gypsum powder machine

-

Supplier: Hebei Lvjoe Machinery Manufacturing Group Co., Ltd. -

Region: Hebei, China -

Contact: Ms Maria Zheng -

Price: $300000.00 /set -

Min. Order: 1 set

| Power(W): | 200-800KW; | After-sales Service: | Service Machinery Overseas; |

| Application: | gypsum powder production line; | Supply Ability: | 12 Set/Sets per Year; |

| Features: | Energy-saving; | Control System: | PLC; |

| Weight: | Depends Capacity; | Certification: | ISO+CE; |

| Place of Origin: | Hebei China; | Warranty: | 1 YEAR; |

| Voltage: | 380V/50HZ; | Condition: | New; |

| Port: | Tianjin port; | After-sales Service Provided: | Field installation, commissioning and training; |

| Automatic Grade: | Automatic; | Installation: | Professional Engineers Assigned; |

| Payment Terms: | L/C,T/T; | Machine Type: | Ramond Mill, crusher; |

| Packaging Detail: | suitable for long distance transportation in containers or according to your requirement; | Raw material: | Natural Gypsum Ore; |

| Applicable Industries: | Building Material Shops,Construction works ; | Annual Capacity: | 15000-300000 Tons; |

| Type: | Full-automatic; | Brand Name: | LVJOE; |

| Technology: | Germany; | Fuel: | Gas Oil Gas; |

| Dimension(L*W*H): | NO Standard; | Advantage: | High Productivity; |

Contact : Kathy Kan

Tel : +0086 13931862405

Wechat : +0086 13931862405

Skype : kathy8227

www.lvjoe.com

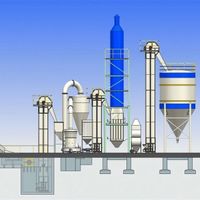

Gypsum Powder Production Line

1. Brief Introduction

The gypsum stone is crushed into granule less than 25mm with crusher.It’s stored in raw material silo,then conveyed into grinding mill to make gypsum powder.The powder is classified through a classifier. The qualified powder in required fineness shall be carried to the calciner, while the unqualified powder shall be returned to the grinding mill for furhter process. The calcined gypsum powder (it’s usually called Plaster of Paris) shall be stored in the finished product silo for preparation of plasterboard raw material.

2.The flow cart of the craft

Jaw crusher--Hammer crusher--Lifter--Nateriak silo--Measuring pump--Mill--Selecting powder machine--Lifter--Raw materials silo--Screw feeder--Fluidized bed furnace--Eletrostatic cleaning--Cooling--Lifter-Finisher material silo

The core technology ---The fluidized bed furnace

1) Simple structure, not easy to damage

2) Space-saving,intensive equipment

3) Low cost of energy

3. Product showing

4.Equipments and technical paremeters

5.Workers distribution on site

The Crusher System: 2 person/ day (including the forklift driver)

The Mill System: 1 person/ eight hours (that is 3 people/ day)

The Calcine System: 1 person/ eight hours (that is 3 people/ day)

The Heat Supply System: 2 people/eight hours(that is 6 people/day)

Electrical Engineering: 1 person/ day

Machinery Maintenance: 1 person/ day

In total: 16 person

6. Product output

The time of production: 300 days/year×24 hours

The output of one hour: ≥4.2T/hour (finished powder)

7. Energy consumption

Coal: :<45Kg/t standard coal (finished powder)

Electric: :≤40KWH / t (finished powder)

8.The related parameter of the product (GB9776-88 calcined gypsum)

1) Fineness:≥80 mesh

2)Antiflex strength (it is related to the raw material ): ≥1.8Mpa; compression strength: ≥3.0Mpa

3) Main component:

semi-hydrated gypsum content: ≥80% adjustable

dehydrate gypsum content: <5% adjustable

Soluble anhydrous gypsum: <5% adjustable

4) The initial setting time: 3~8min adjustable;

The final setting time: 6~15min adjustable

5)Standard consistency: 78~85% adjustable

7. Company Introduction

Welcome to Hebei Lvjoe Machinery Manufacturing Co., Ltd.

It owns the professional in designing and manufacturing all kinds of industrial equipments.

Our company has 300 workers, more than 80 sets of processing machines.

It was established in 1998.Therefore,it has rich experiences and mature technology.

-

The best-selling advanced pure calcined gypsum powder production line

-

Clirik Gypsum Vertical Mill is a high-quality grinding equipment.

-

Complete gypsum production line with calcining plant in gypsum manufacturing plant

-

Gypsum board machine German gypsum board production line adopts Knauf technology

-

Latest Technology Gypsum Calcination Best Performance Construction Gypsum Making Machine Gypsum Powder Production Machinery Factory

-

Gypsum board production line

-

On-site installation of gypsum powder production line manufacturers equipped with gypsum powder mills

-

2022 Precipitated Calcium Carbonate Gypsum Processing Plant 2.7-40t/h Gypsum Powder Production Machine Gypsum Powder Production

-

Large capacity and low investment cost gypsum powder production plant/gypsum powder production line for sale

-

2022 Ex-factory Price Gypsum Powder Making Machine/Fully Automatic High Yield Gypsum Powder Production Line

Other Products

-

$400000.00 / set

$400000.00 / set -

$280000.00 / set

$280000.00 / set -

$300000.00 / set

$300000.00 / set -

$260000.00 / set

$260000.00 / set -

$385000.00 / set

$385000.00 / set