Good quality drying coal grinding mill price, Cement limestone Small scale ball mill, gold ore rock wet ball mill

-

Supplier: Henan Baichy Machinery Equipment Co., Ltd. -

Region: Henan, China -

Contact: Ms Eva Zhao -

Price: $2470.00 / >=2 sets -

Min. Order: 2 sets

| Capacity(t/h): | 0.2-1.5 t/h; | Dimension(L*W*H): | 600X900; |

| Condition: | New; | Cylinder Rotating Speed(r/min): | 26-36; |

| Selling Units: | Single item; | After-sales Service Provided: | Video technical support,Free spare parts,Online support,Field installation, commissioning and training,Field maintenance and repair service; |

| Showroom Location: | None; | Warranty of core components: | 1 Year; |

| Output size: | 5-47 Micron; | Core Components: | Bearing,Gearbox,Gear; |

| After sale service: | Engineer Avalable; | Weight: | 0.8-2 t; |

| Product name: | Lab Jar Mill; | The Machines classification: | Granding Mill Machine; |

| Spare parts supplying: | Life Long Provide; | Name: | Small scale ball mill gold ore rock wet ball mill with best pric; |

| Video outgoing-inspection: | Provided; | Application: | Ore; |

| Single package size: | 80X50X70 cm; | Applicable Industries: | Construction works ,Energy & Mining; |

| Certification: | ISO, CE; | Type: | Ceramic Ball Mill; |

| Single gross weight: | 68.0 KG; | Place of Origin: | Henan China; |

| Feeding size: | 0-25mm; | Packaging Detail: | Wood package,Plactic package,Nude; |

| Machinery Test Report: | Provided; | Marketing Type: | Hot Product 2019; |

| Brand Name: | BAICHY; | Warranty: | 1 Year; |

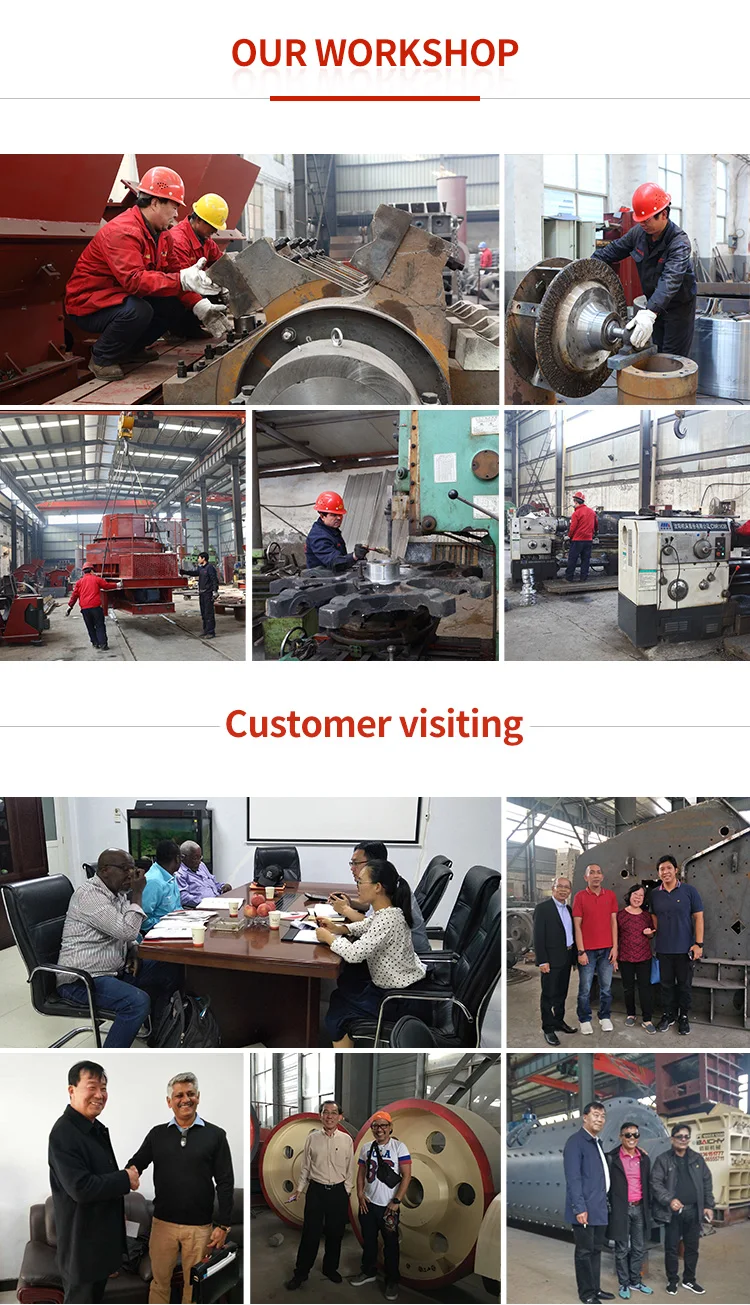

| Local Service Location: | None; | Factory visit: | Welcome; |

| Motor Type: | AC Motor; | Package Preview: | ; |

1. We are factory and be able to give you the lowest price than market one;

2. Our products have been exported to over 80 countries and widely used in global mining and construction industry;

3. we have a professional after-sale service team to promptly and thoroughly solve your problems;

4. Provide free process design.

Ball Mill is a type of grinder used to grind materials into an extremely fine powder mainly for use in the mineral processing industry. Ball Mills can grind various ores and other materials either wet or dry, depending on requirements.

Baichy Ball Mill is a key equipment to grind the crushed materials, which is widely used in the manufacturing industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics.

Dry type ball grinding mill is to grind feldspar, glass, dolomite, quartz, silica sand etc. Using ceramic lining plate, the raw material could keep high purity. It also could be get very fine powder such as 1500 mesh together with air classifier machine.

[ Capacity ]: 0.62–90 t/h

[ Applicable Material ]:

Ball mill is key equipment for grinding materials after crushing process. It is used to grind kinds of materials into fine powder 20-75micrometer. Based on discharging type, It could be grate type,overflow type etc.

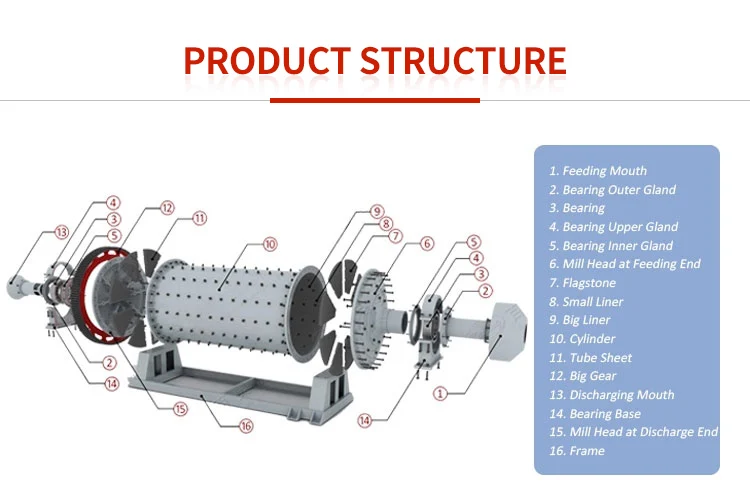

Working principle

Ball mill grinding machine is a kind of horizontal drum-type grinding mill with external gear and double bins. Materials goes evenly through quill shaft in feeding device into the first bin, which has ladder lining or ripple lining with steel balls in different specifications.Steel balls are taken to a certain height by centrifugal force from drum rotation and then fall. Thus it will give a heavy blow to materials, playing a role of grinding. Materials after crushed in the first bin shall enter bin across single-layer diaphragm into the second, which is provided with flat lining with steel balls, to go through further grinding. The ground materials are discharged through the discharging board thus the grinding process is finished.

| Model | Cylinder Rotating Speed (r/min) | Ball weight (t) | Feeding Size (mm) | Discharging Size (mm) | Capacity (t/h) | Power (kw) |

| 900×1800 | 38 | 1.5 | ≤20 | 0.075-0.89 | 0.65-2 | 18.5 |

| 900×3000 | 38 | 2.7 | ≤20 | 0.075-0.89 | 1.1-3.5 | 22 |

| 1200×2400 | 35 | 4.6 | ≤25 | 0.075-0.6 | 1.6-5.8 | 37 |

| 1200×4500 | 35 | 5.5 | ≤25 | 0.074-0.4 | 1.6-5.8 | 55 |

| 1500×3000 | 29 | 9 | ≤25 | 0.074-0.4 | 2-7 | 75 |

| 1500×5700 | 29 | 17 | ≤25 | 0.074-0.4 | 3.5-6 | 110-130 |

| 1830×4500 | 25.4 | 15 | ≤25 | 0.074-0.4 | 4.5-12 | 155 |

| 1830×6400 | 24.1 | 21 | ≤25 | 0.074-0.4 | 6.5-15 | 210 |

| 1830×7000 | 24.1 | 23 | ≤25 | 0.074-0.4 | 7.5-17 | 245 |

| 2100×4500 | 23.7 | 24 | ≤25 | 0.074-0.4 | 8-43 | 245 |

| 2100×7000 | 23.7 | 26 | ≤25 | 0.074-0.4 | 8-48 | 280 |

| 2200×4500 | 21.5 | 27 | ≤25 | 0.074-0.4 | 9-45 | 280 |

| 2200×6500 | 21.7 | 35 | ≤25 | 0.074-0.4 | 14-26 | 380 |

| 2200×7000 | 21.7 | 35 | ≤25 | 0.074-0.4 | 15-28 | 380 |

| 2400×3000 | 21 | 23 | ≤25 | 0.074-0.4 | 30-50 | 245 |

| 2400×4500 | 21 | 30 | ≤25 | 0.074-0.4 | 40-60 | 320 |

| 2700×3600 | 20.7 | 40 | ≤25 | 0.074-0.4 | 45-80 | 430 |

| 2700×4500 | 20.7 | 48 | ≤25 | 0.074-0.4 | 50-90 | 430 |

| 2700×13000 | 20.7 | 60 | ≤25 | 0.074-0.4 | 50-90 | 630 |

| 3200×4500 | 18 | 65 | ≤25 | 0.074-0.4 | -- | 800 |

1. Are you manufacture or trading company?

We are factory, established in 2003.

2. How long is your delivery time?

7-10 days for the stock, 15-30 days for the mass production.

3. What is your payment method?

30% deposit in T/T advance, 70% balance before shipment.

4. How long is the warranty? Does your company supply the spare parts?

One year. Spare parts for you at lowest cost.

5. If I need the complete crushing plant can you help us to build it?

Yes, we can help you set up a complete production line and give you related professional advice. We had already build many mining projects in China & Overseas.

-

High efficiency rock gold grinding equipment wet disc grinder for sale

-

Professional 1000 tons/day cement grinding station ball mill price

-

Black graphite vibrating ball mill

-

Nano powder steel ball mill grinder laboratory grid ball mill with grinding ball grinder

-

Small gold ore mill, small wet mill, small gold ore mill

-

Diesel engine ball mill for gold mine development for sale

-

1600 gold mill with gearbox, china wet disc mill for sale

-

Superfine Powder Complete Production Line Fluidized Bed Jet Mill

-

Energy-saving gold mine rock crusher quartz gold ore stone mill small gold ball mill

-

1100 wet mill reducer 400 gears

Other Products

-

$99999.00 / set

$99999.00 / set -

$7714.00 / piece

$7714.00 / piece -

$5000.00 / set

$5000.00 / set -

$5600.00 / set

$5600.00 / set -

$24580.00 / set

$24580.00 / set -

$23200.00 / set

$23200.00 / set -

$7714.00 / set

$7714.00 / set