Ultrafine micron calcite grinding mill equipment, mine pulverizer superfine powder limestone coal raymond grinder machine price

-

Supplier: Henan Baichy Machinery Equipment Co., Ltd. -

Region: Henan, China -

Contact: Ms Eva Zhao -

Price: $5600.00 /set -

Min. Order: 1 set

| output size (mm): | 0.613-0.033; | Marketing Type: | Ordinary Product; |

| Capacity(t/h): | 0.4-1.8 t/h; | Roller Size(L*H)(mm): | 210*150; |

| product keywords: | ginding mill wear parts; | Warranty: | 1 Year; |

| Core Components: | PLC,Engine; | Factory of High pressure Suspension mill: | welcome to visit; |

| Roller No.: | 3; | Showroom Location: | None; |

| Port: | Qingdao,shanghai,tianjin; | Condition: | New; |

| Video outgoing-inspection: | Provided; | Color of High pressure Suspension mill: | as you need; |

| Product name: | superfine powder limestone coal raymond grinder machine price; | Place of Origin: | Henan China; |

| Payment Terms: | L/C,Western Union,D/P,T/T; | Packaging Detail: | container small parts packed in wooden boxes or up to you; |

| Local Service Location: | None; | Warranty of core components: | 1 Year; |

| Grind ring Dia.and hegiht(mm): | 650*150; | Motor Type: | AC Motor; |

| Brand Name: | BAICHY; | Dimension(L*W*H): | 4100*3300*4500 mm; |

| Machinery Test Report: | Provided; | Supply Ability: | 30 Set/Sets per Month; |

| After-sales Service Provided: | Video technical support,Field maintenance and repair service; | Weight: | according to the product; |

| Package Preview: | ; | Max.feed size(mm): | 15; |

| Certification: | CE,ISO9001:2008; | spare parts: | supply the using life; |

| Applicable Industries: | Building Material Shops,Manufacturing Plant,Machinery Repair Shops,Construction works ,Energy & Mining; | Type: | milling machine; |

Ultrafine micron calcite grinding mill equipment, mine pulverizer superfine powder limestone coal raymond grinder machine price

[ Capacity ]: 0.5–60 t/h

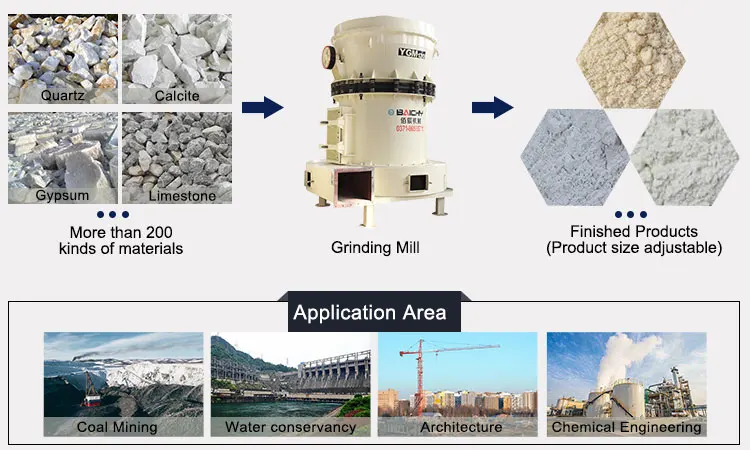

[ Applicable Material ]:

Raymond mill, also known as raymond grinding mill, raymond roller mill and raymond grinder, is suitable for grinding non-flammable and non-explosive materials.The finished powder size can be adjusted between 30 and 425 mesh(0.613mm-0.044mm).

Working principle

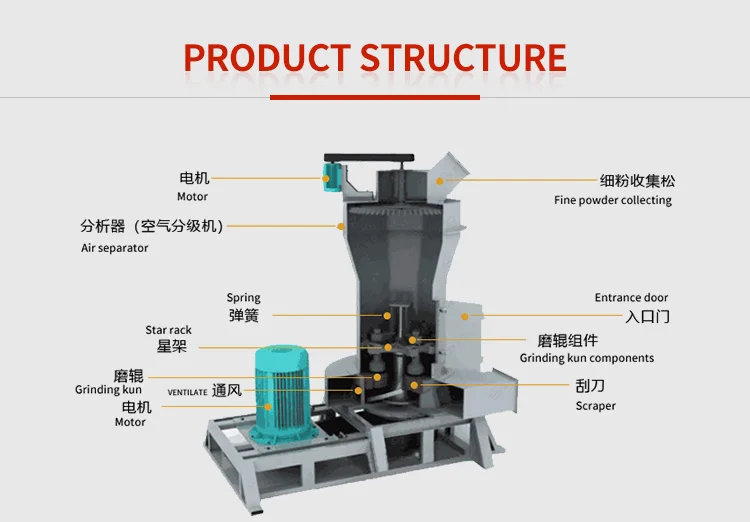

1. The whole structure of Raymond Mill machine is mainly including the host, analysis machine, plumbing fixtures and the blower, according to user needs, it can be equipped with crusher, elevator, electromagnetic vibrating feeder, electric control cabinet etc.

2. After materials crushed to the desired particle size, enter into the storage hopper by the elevator, and then through vibrating feeder enter into grinding chamber of Raymond mill uniform continuously.

3. Due to the centrifugal force when rotating, the rollers swings outward, pressed on the grinding ring, shovel blade scoop up materials, then sent them between grinding roller and grinding ring, due to the grinding roller roller rolling to achieve crushing purpose.

4. After grinding material, the powder along with the circulating air which made by blower, is brought into the analysis machine for sorting, coarse material will regrind. Qualified powder along with the air enters into finished product cyclone powder collector, then discharge powder tube, that is finished product.

5. In the grinding chamber of Raymond mill, because there are certain moisture in the grinded material, when grinding, it will generate heat, moisture evaporates, and the pipe interface of the whole is not tight, the outside air is drawn into making the circulation pressure increased to ensure that the mill wok under negative pressure. The increased air flow enter into the dust through the duct, at last enter into the atmosphere after purification.

| Model | Roller | Roll Dia. (mm) | Roll Ring Size (mm) | Max. Input Size (mm) | Output Size (mm) | Capacity T/Shaft | Power (Kw) | Dimension | |

| 3R | 1510 | 3 | 150*100 | 570*100 | 15 | 0.125-0.044 | 0.8-10 | 7.5 | 3200*1200*3800 |

| 2115 | 3 | 210*150 | 630*150 | 15 | 0.125-0.044 | 1-12 | 15 | 3500*3300*4500 | |

| 2615 | 3 | 260*150 | 780*150 | 20 | 0.125-0.044 | 1.5-20 | 18.5 | 4650*3600*5100 | |

| 2715 | 3 | 270*150 | 830*150 | 20 | 0.125-0.044 | 2-28 | 22 | 4700*3600*5100 | |

| 3015 | 3 | 300*150 | 875*150 | 25 | 0.125-0.044 | 2-35 | 30 | 5300*4100*5200 | |

| 4R | 3016 | 4 | 300*160 | 890*160 | 25 | 0.125-0.044 | 3-36 | 30 | 5400*4100*5200 |

| 3216 | 4 | 320*160 | 970*160 | 25 | 0.125*0.044 | 4-45 | 37 | 7100*5900*7900 | |

| 3220 | 4 | 320*200 | 970*200 | 25 | 0.125-0.044 | 4-55 | 45 | 9900*5800*1058 | |

| 5R | 4119 | 5 | 410*190 | 1270*190 | 30 | 0.613-0.044 | 8-60 | 75 | 9200*7250*9700 |

Jaw crusher

Impact crusher

Cone crusher

Ball mill

Grinding mill

Mobile crusher

1. Are you manufacture or trading company?

We are factory, established in 2003.

2. How long is your delivery time?

7-10 days for the stock, 15-30 days for the mass production.

3. What is your payment method?

30% deposit in T/T advance, 70% balance before shipment.

4. How long is the warranty? Does your company supply the spare parts?

One year. Spare parts for you at lowest cost.

5. If I need the complete crushing plant can you help us to build it?

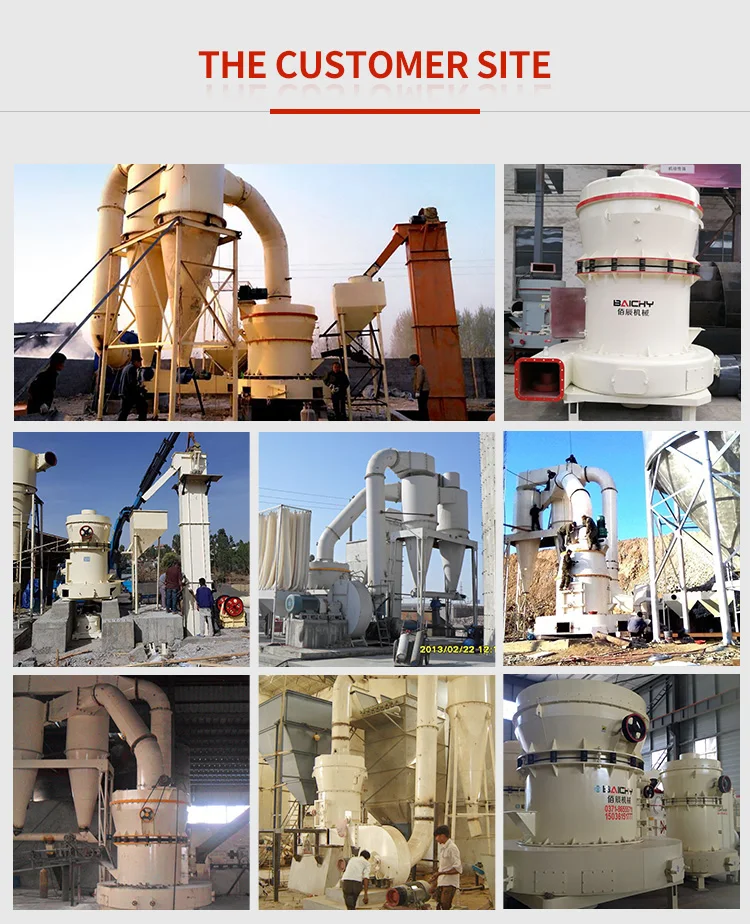

Yes, we can help you set up a complete production line and give you related professional advice. We had already build many mining projects in China & Overseas.

-

High efficiency rock gold grinding equipment wet disc grinder for sale

-

Professional 1000 tons/day cement grinding station ball mill price

-

Black graphite vibrating ball mill

-

Nano powder steel ball mill grinder laboratory grid ball mill with grinding ball grinder

-

Small gold ore mill, small wet mill, small gold ore mill

-

Diesel engine ball mill for gold mine development for sale

-

1600 gold mill with gearbox, china wet disc mill for sale

-

Superfine Powder Complete Production Line Fluidized Bed Jet Mill

-

Energy-saving gold mine rock crusher quartz gold ore stone mill small gold ball mill

-

1100 wet mill reducer 400 gears

Other Products

-

$99999.00 / set

$99999.00 / set -

$7714.00 / piece

$7714.00 / piece -

$5000.00 / set

$5000.00 / set -

$24580.00 / set

$24580.00 / set -

$23200.00 / set

$23200.00 / set -

$7714.00 / set

$7714.00 / set -

$2470.00 / set

$2470.00 / set